PROPOSAL

The FAMU-FSU College of Engineering solar car club

will be building a new racing car (Sunsation II)

to compete in the 2001 solar challenge. A mechanical

team has been formed to design and build a new front

and rear suspension system for this new solar car.

The duties of designing the front and rear suspension

have been split into two teams of three mechanical

engineers and one electrical engineer, our task being

the new front suspension design. The design of a

solar car is extremely complex therefore the project

has been split into two semesters.

The first phase of this project included: Determine

shock/spring configuration, analyze suspension

geometry, design suspension connection, minimize scrub,

write preliminary design report, engineer drawings for

each component, analyze composite chassis material,

material selection, and ordering parts. The second

phase of this project continuing next semester, includes:

IMPROVMENT

Better team and group organization.

Better work scheduling and time management.

Suspension connection: First of all we need

to connect the suspension for the double A-arm and bulkhead.

Next the engineering drawings need to be done for the

suspension and stirring systems.

The material for the suspension and the stirring

systems is selected depending on the strength and stiffness.

Ordering parts for the break assembly needs to be done

next. Because without ordering the parts like springs and

break assembly the design cannot be carried on to the next level.

The forces that the weight of the body impacts to the

suspension need to be known. In other words force analysis have

to be calculated.

The drawings and geometric calculations for the stirring

system need to be done either using pro-engineer or AutoCAD.

Stress analysis for the composite materials have to be

performed before incorporating into the design.

The next stage is to test the suspension by performing

stress analysis.

Analyzing the performance of the suspension is very

critical in the design process to check out if any errors occur.

Machining the parts for the suspension and stirring

systems follows.

Finally all the parts need to be assembled.

Projected Budget

Bulk metal (aluminum/iron) 600.00

Shocks 1200.00

Wheels 1200.00

Tires 1000.00

Hardware (Bolts/Nuts) 300.00

Steering linkage 500.00

Steering Box 500.00

Brake calipers 400.00

Brake rotors 700.00

Rotor hubs 800.00

Brake lines 200.00

Master cylinder 200.00

Pedal Assembly 250.00

Total 7850.00

Schedule

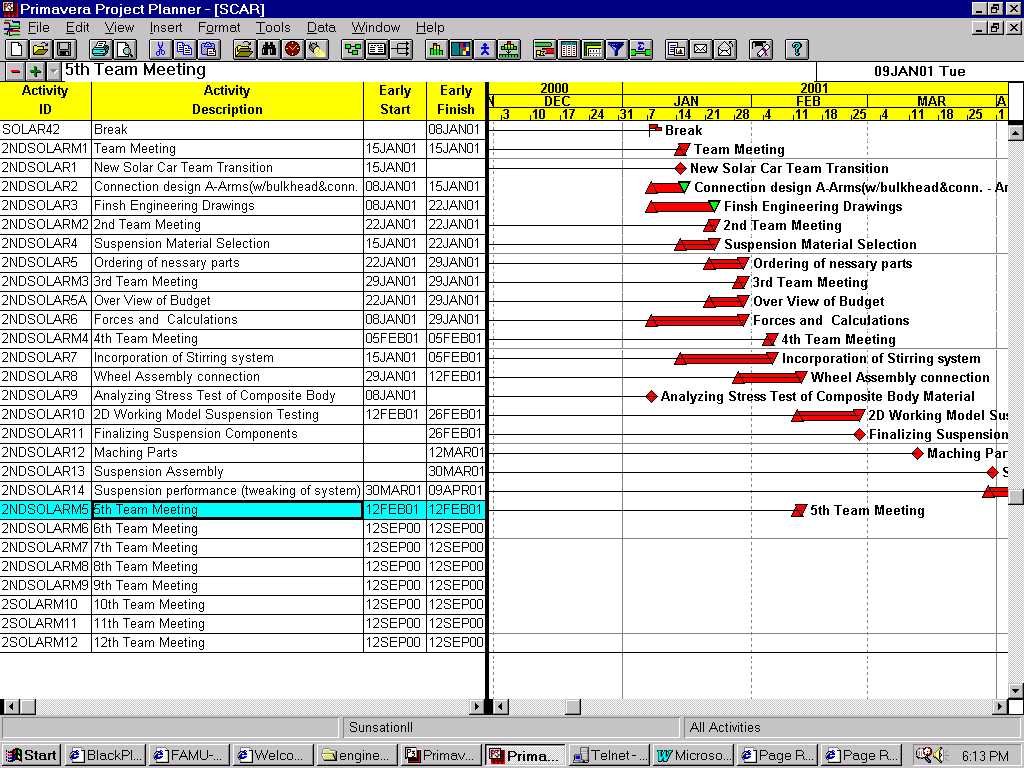

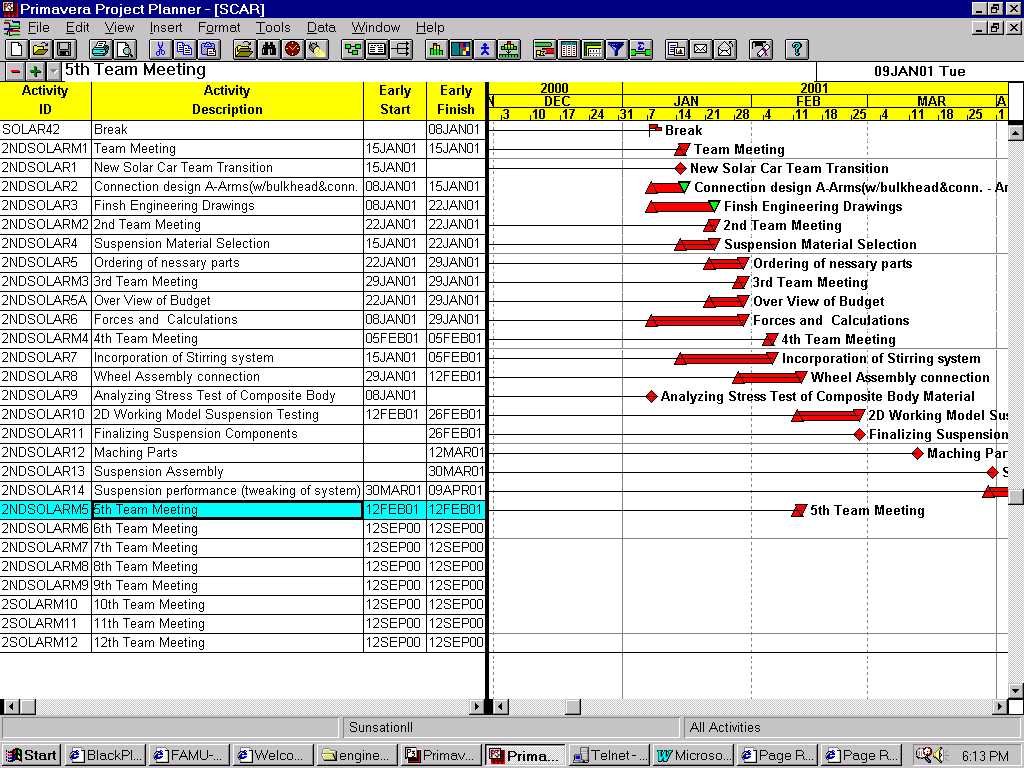

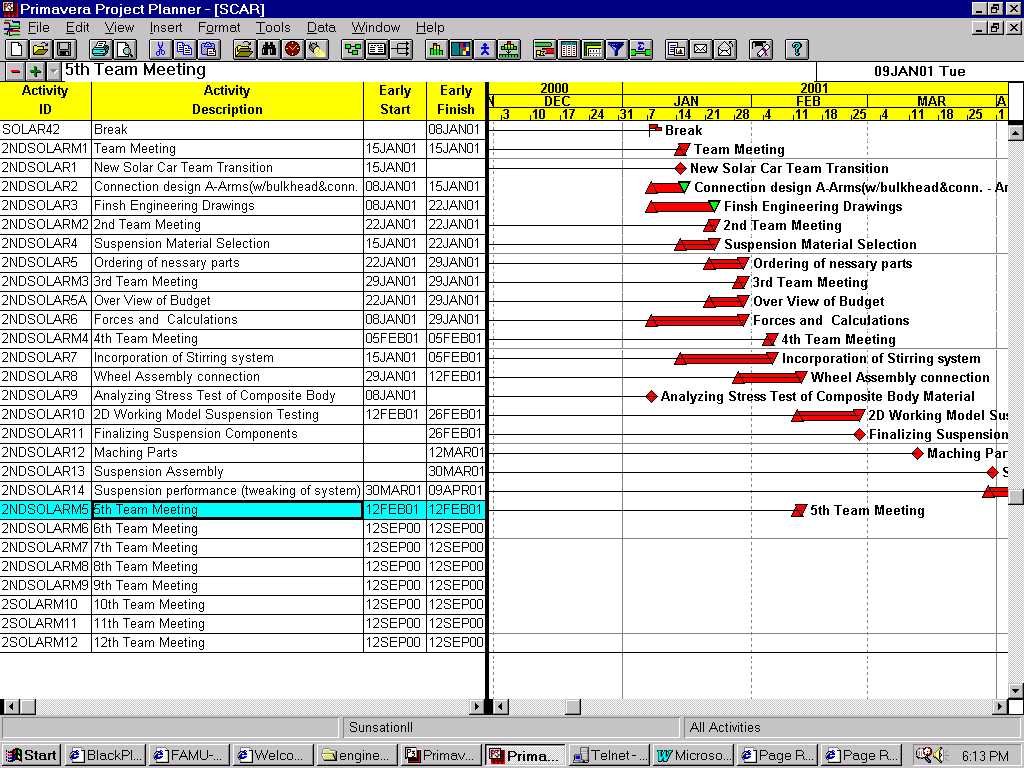

A productive continuation of a project needs a well thought out

and organized schedule. This semesterís schedule was actually

well though out but not too organized, causing fallbacks in the

goals set at the beginning of the semester. However falling short

of the desired task to be completed does not mean that they will

never be completed. Therefore a new schedule for next semester

was thought up and layout in Figure 1 below.

This primavera schedule lays out the goals (unfinished task) and

the projected timetable on when they will be started and finished.

It also has a projected schedule of the solar car team meeting dates.

These projected meeting dates are not yet confirmed though.

Figure1: Second Phase Projected Schedule

Figure1: Second Phase Projected Schedule

Conclusion

In conclusion, we have given a basic over view of our problem

statement and required task needed to complete the front suspension

for Sunsation II. As stated in this proposal the project has moved

from phase I to phase II. Phase II of this project is where the

design and concept analysis are tested. Although phase I was very

productive there was still room for improvement as stated earlier.

Our team has looked at the mistakes it has made during phase I, and

discussed possible solutions. These solutions will be implemented

during phase II, which will help in the quality of our final design.

Figure1: Second Phase Projected Schedule

Figure1: Second Phase Projected Schedule

Figure1: Second Phase Projected Schedule

Figure1: Second Phase Projected Schedule