The diameter of these pins must be given to determine

the cross sectional area and the resulting shear stresses

in the pins.

Analysis of this concept must also take into account

the shear forces acting on the pins that hold the disks

in place. If these forces are too great within the

operating torque limits, then the pins will shear before

the torque limiter even begins to compensate for any

overloaded condition.

And the spring constant

is:

Therefore the required spring force to keep the disk

at an angle during normal operation is:

The spring constant can then be found by

specifying the length that the spring must travel:

In equilibrium the Moment equation is equal to 0, therefore

we can solve for the spring force.

Therefore it appears that a material may be chosen for

the pins to withstand the shear

stresses involved.

And the Tensile yield Strength is:

For Type 301 cold rolled stainless steel:

In this case, this steel would not be suitable for the

pins

However the Tensile yield Strength is:

For 1040 hot rolled steel The ultimate tensile strength

is :

Depending on the material chosen for the pins, this

design may or may not hold up to the required torque

levels.

The shear force on the pins will depend on the angle

of the disk and the Force from the maximum allowable

torque of the shaft:

Given an angle of the disk with respect to the axis

perpendicular to the axis of rotation of the shaft:

The geometry of the design will place a normal force

on the second disk as a result of the force from the

torque. Based on the angle of the disk this component

of the force can be found. The reaction force from

the second disc is equal to this force when the system

is in equilibrium.

The Force located at this point on the

shaft can be calculated using the equation:

A tangential force will result on the end of the shaft

dependant on the radius of the point in question

For a given radius:

With a given torque limit:

Seizure Recovery System for Fuel System Distributor

Concept #4

The distance from the point of contact of the spring

to the pivoting axis of disk 1 must also be specified.

However this distance will change as the disk is tilted.

Using the distance between these two points when the

disk is in a vertical position, this length can be

calculated for any angle:

The distance of the force acting on disk one from the

pivoting axis of the disk

is found from the equation:

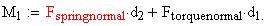

But first the distances d2 and d1 must be calculated

The width of the disks must be specified to find the

distance between the two pivoting axes of the disks

By analyzing the moment about the pivoting

axis of disk 1 we can solve for this spring force:

During normal operation this normal force is balanced

by

a force from the spring in a direction that directly

opposes it.

The normal force acting on the

disk from the spring is determined by: