Final Design

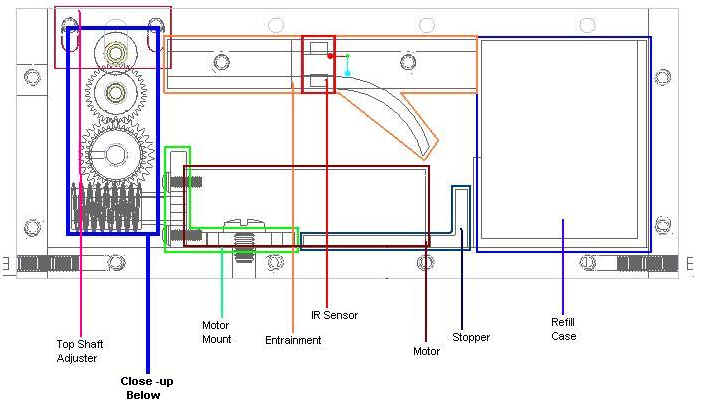

Shown are different views of the final prototype design. No front cover is shown for viewing purposes.

Click to enlarge

30deg 60deg 90deg 120deg 150deg

Prototype shown with front cover in place.

Click to enlarge

The design works as follows: After the motor is activated by the computer, it spins the worm which is attached to the motor shaft. The worm then spins the worm gear, which spins the bottom shaft. A spur gear is attached to this bottom shaft, which is also spun by the worm gear. An identical spur gear is meshed with the first gear. This second spur gear pins the middle shaft, which spins the bottom knurled rollers. This spins the top knurled rollers. The pill package is dispensed through the knurled rollers.

The Infrared sensor detects the pre-cut notches on the side of the pill. When one pill package needs to be dispensed, the motor is activated until the infrared sensor reads itself (one pill package is dispensed.) There is one notch per pill package. This is the motor control facet of the design. Note the IR sensor is lodged in the entrainment.

Side View of Phase One End Result. The blue box is shown in more detail below.

Close-up of Enclosed Blue Area