There are many types of lifting

devices that were explored in the research for this project. The Shaw Industries

plant in Bainbridge uses a lifting system that the group thought could be built

upon to meet the customer’s needs. Original designs that the group discussed

involved using the current design with additional legs incorporated for

increased lifting height. This, however, did not turn out be feasible and

additional modifications had to be made.

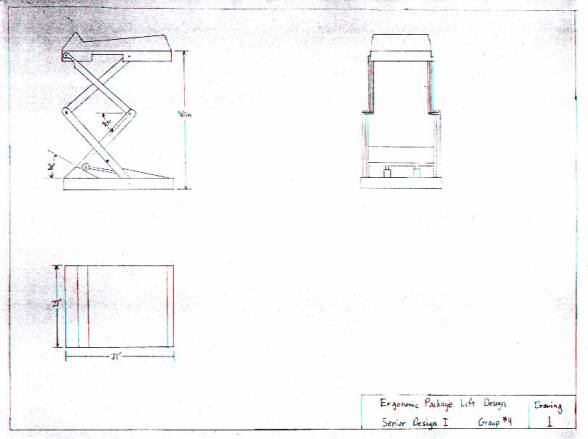

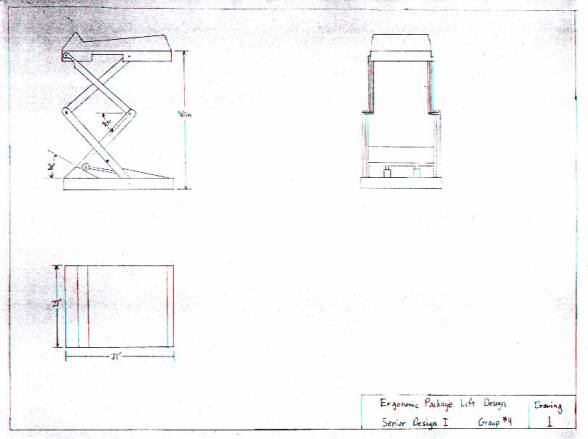

The second evolution of the design

had legs of 30 inches inclined at an angle of 45°.

This design ran into many problems dealing with the packaging of the legs

underneath the lifting pan when it folded down. The cross member that are used

for support would not allow for complete collapsing of the legs. This meant that

a new solution had to be found.

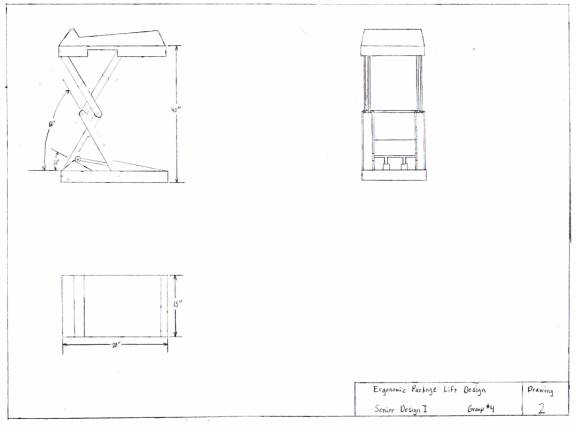

Figure 5:

Original Sketch

To answer this problem it was decided to move the pivot point higher up

on the links and increasing the angle of incline. The incline was changed to 60°

and this resulted in the link lengths being decreased to 23 inches. This managed

to solve the problems resulting form the space constraints. All of the inner

working parts have to be confined to and area of 17 inches by 30 inches. Now

they could be fully collapsed on top of each other without parts banging

together and overlapping each other.