Program an Economizer :

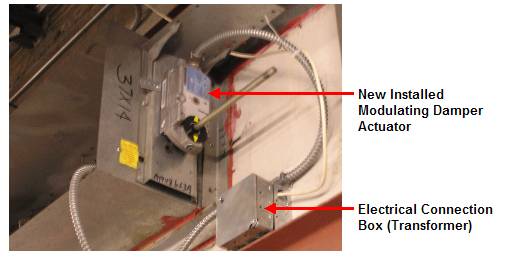

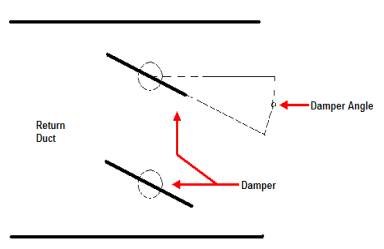

The existing two position dampers on the return duct inlets had to be changes to modulating dampers. The rest of the equipment such as dampers, humidity sensors and the ductwork were already in place.

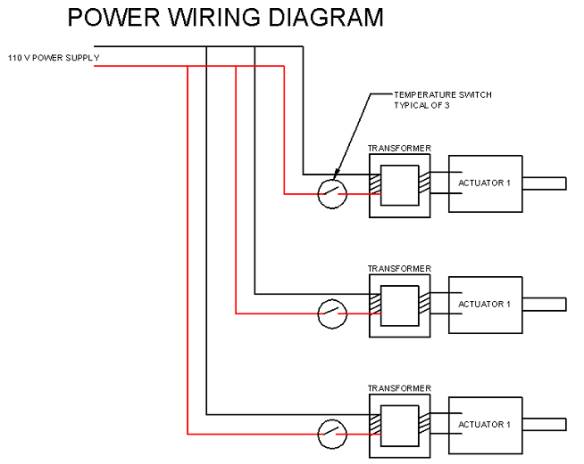

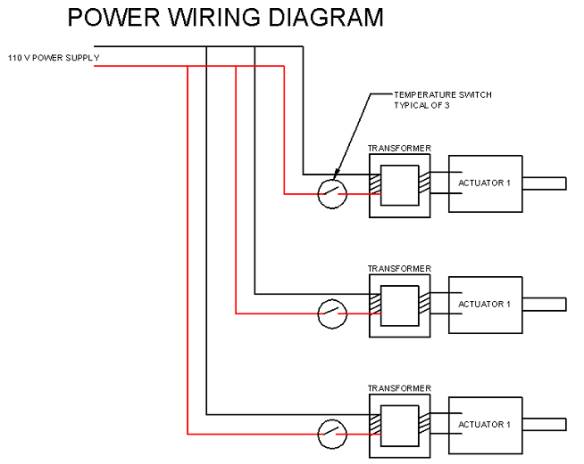

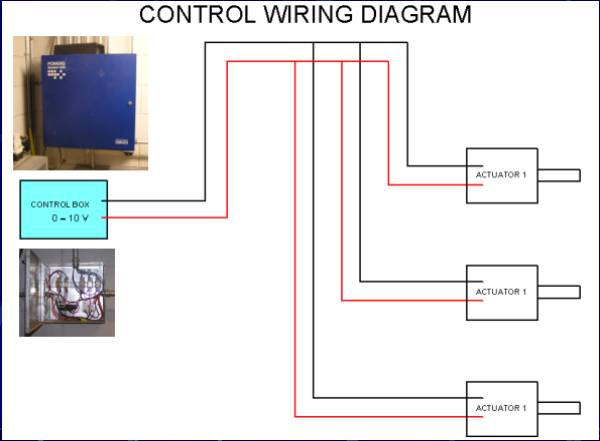

The Figures below show the changes that were made in the wiring program.

Below are pictures before and after the new dampers were installed.

Results:

A test was performed to determine the amount of increases outside air that could be introduced to the system by changing the damper position.

This air handling unit supplies 30,500 CFM of air to the spaces, 15,000 of this needs to be outside air. The test concluded that the damper position should not be closed much more than 75o. The reason behind this is the increases velocity in the ventilation duct caused the noise level to rise above a reasonable level.

Control Program : John Kynoch programmed the system based on the following information.

If the outside air dry bulb temperature (Tdb) is between 65oF and 75oF and the relative humidity (RH) is less than 60% then the actuator position should be 60o.

If Tdb for the outside air is less than 65oF and the outside air RH is less than 70% then set the actuator position to 75o.

The dampers should not be set to the closed position unless called for by the fire protection system because the noise level increases drastically above 80o closed.

In Heating Mode

For heating the Return Air dampers will be set to 100% open, as outside air will need to be minimized. Energy use improvements for heating will mostly be made in changing the supply air temperature setpoint.