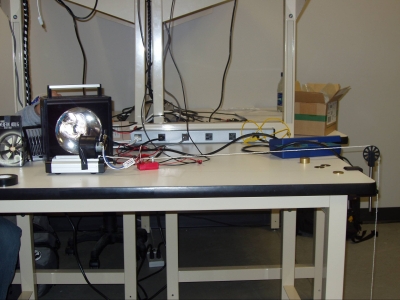

Testing setup for ducted fan and motor

Testing setup for ducted fan and motor with track

Ducted fan mounted and ready to go

Side view

Power source used for initial testing

6 channel 72Mhz FM transmitter

Without track, right before turning the power on

Fan blowing with a small amount of thrust

Measuring the amount of thrust using various hanging masses

Testing is fun!

We concluded that we needed a power source with greater output, like an ATV battery

A and B combined to make foam for molding the body

After mixing the 2 parts together well, it's just like making a cake

Foam mixture cures pretty quickly

Fully cured foam blocks

Forming the foam to fit our needs

The foam has to be cut just right

Resulting molds

Fiberglass sheets to be used for the body

The fiberglass sheets soaked in resin are placed onto the mold

Moving quickly and carefully is a must since the resin tends to dry at a fast rate

Out to dry

Let's see if our new motor, power source, and fiberglass body can attach itself on a vertical surface

Almost there...

Success! Now we know our concept works!

Body mounted with foam wheels

Top view

Angled view

Bottom view

Measurement of an uncut body

Ground clearance

Testing to see wall attachment with ground clearance

Good to go!

We decided that the best way to secure the ducted fan was to mold the fiberglass directly onto it

Ducted fan and fiberglass body out to dry

Brackets for wheel driving motors mounted

Side view

Brackets on two different bodies

Motors mounted on the brackets

Receiver mounted opposite motors

Receiver mounted adjacent motors

Testing the newly mounted motors

To increase traction, various types of tape can be used for adhesive tracks

Rubber band track

Electrical tape track

Double-sided Scotch tape

Side view

Bandage tape track

Side view

Various body types and wheel configurations

Body with receiver, 2 motors, and two speed controls

Front view

We decided that to shave off excess weight (2+ oz) and excess torque from the motor/speed control setup, modified servos would do the job

The mechanical and electrical stops were removed from these position servos to make them run continuous

Servos mounted

Top view

Side view

Raised wheel up front to aid in the horizontal to vertical transition

Only 3 channels were used for the platform, so the 8 channel receiver was swapped out for a smaller receiver to shave off even more weight

Making the transition!

"Stealthy" camouflage paint job done by Ryan, hardly detectable by radar!

Final Design

.

.

|

Testing setup for ducted fan and motor