Design Conception and Selection

Several ideas were generated during the design conceptualization. Shown below are the ideas that the group generated.

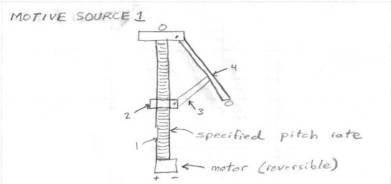

Show above is the Screw-type Tetrahedron over Tetrahedron design.

Proposed Operations: This design called for the center shaft to rotate via a DC motor. Link 2 would move up and down the lead screw, thereby deploying link 4 to the retracted or deployed position

Design Issues: This design was deemed impractical because of parts availability issues (center shaft lead-screw). Vibration damping would be very difficult, adaptation of a vibration damping mechanism would be nearly impossible

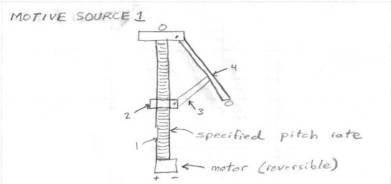

Shown above is a Four-Bar Slider Frame.

Proposed Operations: Slider would move via a linear actuation mechanism, causing it to move up and down thereby deploying or retracting link 2.

Design Issues: Linear actuation device was very difficult to implement into the design. This was overcome by simply utilizing the center shaft as a dual slider mechanism.

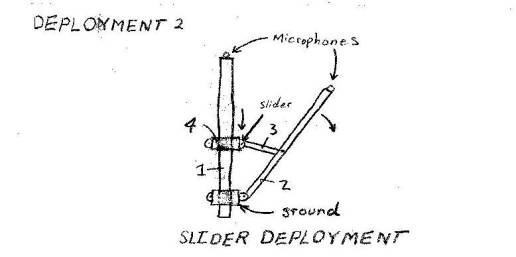

Shown above is the Jointed Tetrahedral Slider Mechanism Frame design.

Proposed Operations: A slider attached to a pulley cable mechanism caused deployment or retraction of link 6, due to movement of the foldable four-bar linkage.

Design Issues: Very difficult to implement cable actuation system, there are no connection points available on foldable four-bar linkage rods. Numerous connection joints allow for more points of vibration initiation caused by the array itself, causing more disturbance in the microphone sensors.

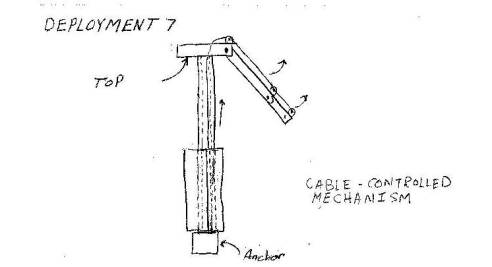

Shown above is a Cable Controlled Deployment Mechanism Frame.

Proposed Operations: External slider is linked to cable pulley system to retract and deploy array.

Design Issues: Again, this design is very impractical to implement, as the slider mechanism in the fully retracted position would interfere with the foldable four-bar linkages.

Final Design Decision Matrix

|

Mechanism |

Price to Produce (0.2) |

Weight (0.15) |

Rigidity (0.05) |

Complexity (# of

parts) (0.1) |

|

A |

4 |

4 |

8 |

5 |

|

B |

8 |

5 |

6 |

5 |

|

C |

7 |

2 |

6 |

5 |

|

D |

1 |

4 |

3 |

1 |

|

Adaptability (0.25) |

Machinability(0.05) |

Vibration Resistance

(0.15) |

Overall Height (0.05) |

Total |

|

4 |

4 |

2 |

10 |

0.481 |

|

8 |

7 |

5 |

10 |

0.9 |

|

3 |

5 |

2 |

10 |

0.3875 |

|

2 |

8 |

3 |

10 |

0.406 |

|

Key |

|

|

A |

Tetrahedron over

tetrahedron screw-type |

|

B |

Four-Bar Slider

Linkage folding down |

|

C |

Jointed Tetrahedral

Slider |

|

D |

Cable Controlled

Deployment |

|

Ratings |

1 |

5 |

10 |

|

Price |

Expensive ($175+) |

Mid-Range ($140+) |

Cheap (>$100) |

|

Weight |

Heavy (+10 lbs) |

Moderate (+5 lbs) |

Light (>5 lbs) |

|

Rigidity |

Soft (Very Flexible) |

Firm (Moderate

Deflection) |

Rigid (No Deflection) |

|

Complexity |

17+ Parts |

15-17 Parts |

>15 Parts |

|

Adaptability |

Complex |

Moderate |

Simple Mounting |

|

Machinability |

Complex |

Mid-Range |

Simple |

|

Vibration Resistance |

Poor |

Moderate |

Outstanding |

|

Overall Height |

<25% Taller than

Robot |

Up to 25% Taller |

Up to 10% taller |

After examining the results of this decision matrix, the most practical design was clearly design B, the Four-Bar Slider Linkage folding down.