|

Final Solution |

|

The filter temperature data should be weighted and averaged based on the importance of the measurement location on or in the filter. This should give an accurate overall thermal model of the filter. The first experimental phase consists of passing a soot-free heat stream of gas through the filter. The temperature data should give a good idea of the thermal response (specific heat capacity) of an “empty” filter. The next phase consists of gradually loading the filter with soot by passing a stream of exhaust gases through the filter. This stream of exhaust gases should closely approximate the normal operation of the vehicle that the filter will be placed on. The temperature measurement devices should be constantly monitored to observe the overall specific heat change of the system. After set time intervals, the filter should be removed from the exhaust system and measured to find out the amount of diesel soot that has accumulated in the filter. The set time interval should be based on assumed time needed to accumulate a significant amount of soot. The shorter the interval of time, the more data will be available for the correlation study. This will make the final system capable of monitoring smaller amounts of soot. The filter soot measurement can be performed using a weight comparison between the original weight of the filter and the weight following engine operation (soot loading). There are also previously mentioned soot measurement methods that were discarded because they were too complicated for utilization during truck operation. These can be utilized in the experimental research at this step to get an accurate determination of the soot content of the filter. Once the soot content of the filter has been determined, the filter should be placed back into the exhaust system and the cycle restarted. This cycle of loading soot and removing to measure soot (while monitoring temperature) should be repeated until the filter is deemed “full” of soot. The final phase is the analysis of the temperature response data. Each overall system specific heat value should be correlated with a measurement of how much soot mass is in the system. This should result in a chart correlating real time temperature measurements with the amount of soot content in the system, thus solving the project problem. |

|

The Temperature Measurement Method |

|

Experimental Research Setup |

|

Cummins |

|

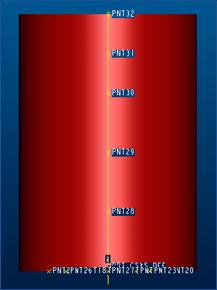

Diesel Particulate Filter |