The Electrical Discharge Machining process is one of the most accurate and low cost processes, when creating complex or simple shapes and geometries within parts and assemblies. EDM is also a very desirable manufacturing process when low counts and high accuracy is required, as well as has quick turn around time. When fabricating the gear and pawl, EDM was very useful in assuring that the angles were machined close to exact as it was designed, to avoid the gear and pawl not fitting together correctly. Another advantage in using the EDM process was that the material chosen for the gear and pawl is an extremely hard material, making this process extremely beneficial in cutting the 17-4 stainless steel.

EDM is sometimes called "spark machining" because it removes metal by producing a rapid series of repetitive electrical discharges. These electrical discharges are passed between an electrode and the piece of metal being machined. The small amount of material that is removed from the work piece is flushed away with a continuously flowing fluid (see the diagram below). The repetitive discharges create a set of successively deeper craters in the work piece until the final shape is produced.

EDM Process:

Figure 7.2.1

Illustration of EDM equipment:

Figure

7.2.2

Figure

7.2.2

EDM is commonly used for making prototype and production parts, which is exactly what was needed in the development of this project.

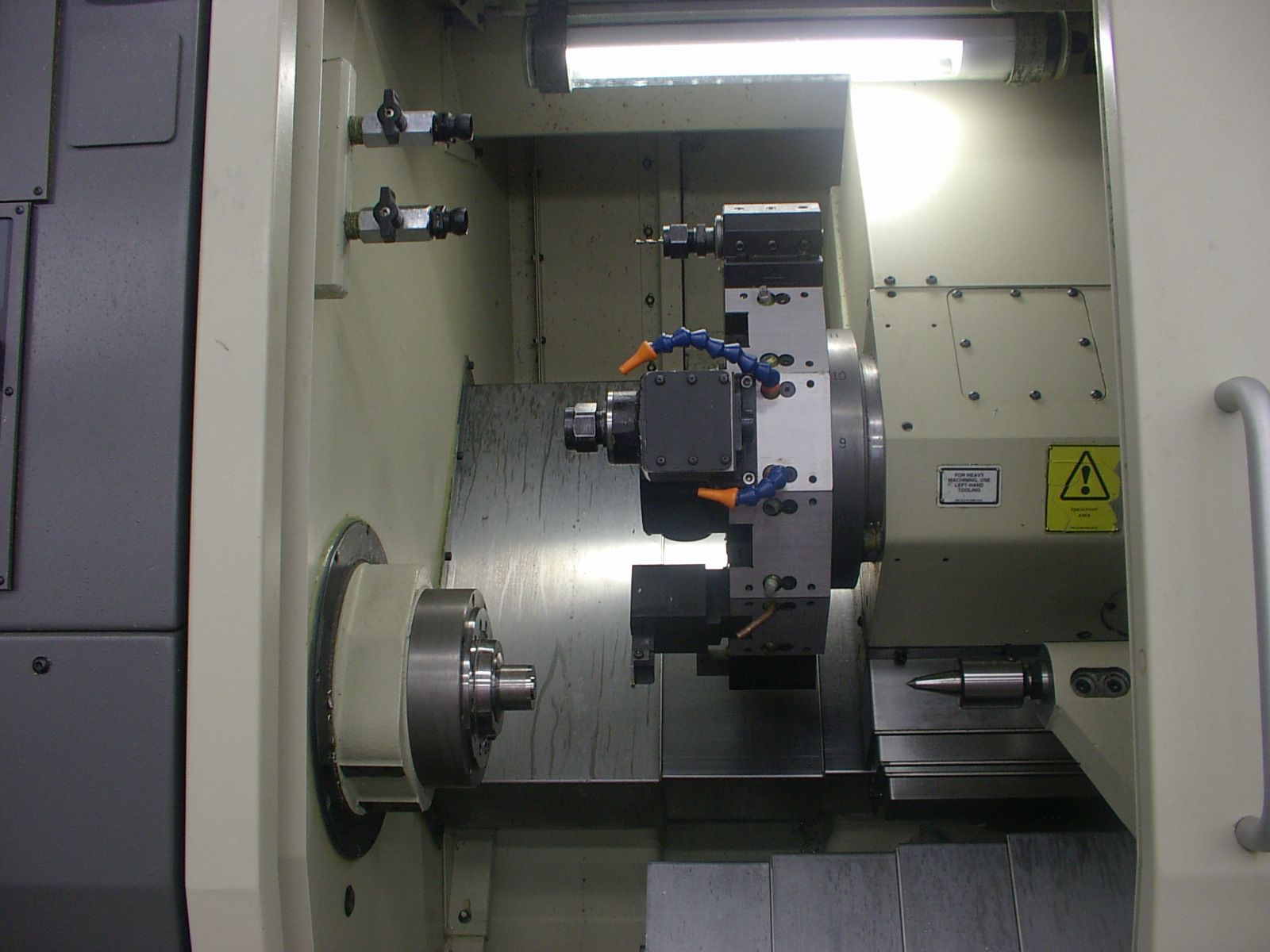

The housing components, as well as the skeleton of the ratchet gear and pawl were machined using the traditional lathe and mill.

Machined Using a Lathe Teeth Angles were EDM Pawl Teeth Angles were EDM

Illustration of Lathe:

Figure 7.3.1

Accuracy and clarity were vital in composing the drawings and tolerances for machining every component of the knee joint. All the parts were properly assigned tolerances on the respective drawings to allow for assembly of the knee joint. The group spent a total of 20 hours in the machine shop. The main parts were successfully fabricated and assembled.