Fuel injection System

Final Design

Pressure Vessel

The

pressure cylinder is where the pressurized Nitrogen and the JP-10 come into

contact and the line pressure is developed.

The cylinder must be strong enough to contain the relatively high

pressures inside without exceeding the failure stress of the material. Since the nozzle designs require operational

pressures up to and including 150psi the design was toleranced to a factor of

safety of at least 2 for 200psi. Given

that this indicates a maximum operational hoop stress of approximately 5.51 MPa

with an outer radius of 8 cm and a thickness of 2 cm. This is well below the failure stress of

steel piping, which averages to around 500 MPa.

An alloy of steel should be used for

numerous reasons. First, the ability of

steel to avoid fatigue failure means that the device can be used much more

often without fear of a rupture when compared to a material such as

aluminum. Second, there are numerous

reliable and cheap surface treatments that can be used on steel. A surface treatment such as Chromium plating

would be favorable for the inside of the vessel to avoid possible oxidation or

other contamination of the fuel.

Finally, steel is readily available and is easily machined using standard

processes.

The finalized design of the pressure

vessel consists of two main parts, the body and the lid. The body can be made through welding a round

plate with an outside diameter of 16 cm and a thickness of 2 cm onto a 24 cm

length of steel pipe with an outer diameter of 16 cm and an inner diameter of

12 cm. The non-welded end should be

inset such that it has a 2 cm long, 1 cm deep lip. This lip should be tapped to accept the

matching threads to be placed on the lid.

Having a well machined threading fitting here helps seal the joint between

the body and the lid so that a gaseous or fluid leak becomes unlikely. A second seal can be accomplished by cutting

a shallow ring into the non-threaded surfaces where the body and the lid meet. Rubber o-rings can be fitted into these cuts

such that when the lid is tightened down a leak proof seal is obtained. These o-rings should have half of their body

sitting above the upper part of the cut when installed into the cuts. A drilled and tapped hole should be placed on

the welded end of the body in a manner which allows an air line quick connect

(such as a Coilhose Pneumatics

Male-Threaded Six-Ball Coupler (A937B4M)).

This quick connect will allow a standard male fitting to inserted in

order to fill the tank with the required pressure of Nitrogen. When not being used for this purpose the line

can be disconnected and the quick connect will provide a leak proof seal for

both the Nitrogen and alternatively the JP-10.

The lid of the pressure vessel can

be simply milled out of a 16 cm diameter round piece of 3 cm thick steel. A cut 1 cm deep and 2 cm wide from the bottom

edge is to be made along the bottom edge of the circle to match the similar

notch in the body of the pressure vessel.

Threads corresponding to the tapped section of the body are also to be

cut into this notched region. At the

center of the lid is a through hole that is drilled and tapped to accept ½” NPT

piping and threads. This hole is to be

used to run the piping system through which the JP-10 will be pressurized and

will flow through when the valve is opened.

Also through the lid should be a drilled and tapped hole that will accept the same type of air

line quick connect as is present at the bottom of the body of the pressure

vessel. This second quick connect

becomes important when the orientation of the pressure vessel needs to be

flipped.

Pressure Vessel Sketch: (all units in cm)

Black represent the body of the pressure vessel, red lines

outline the lid, blue outline the piping, and yellow lines represent quick

connect air line fittings.

Versatility

is a key aspect to the success of this design, and the pressure vessel’s design

reflects this. There are three main

orientations in which the design can be used during experimentation. The fuel delivery system may be set up such

that it sprays the fuel downward, sideways, or straight up. Any one of these orientations may be used by

the Air Force staff, while the design team would recommend that the downward

and upward shots may provide the best results.

This is due to gravity’s influence on the spray pattern. When shot upwards, spray droplets will

eventually run out of momentum and stall in the air, allowing for a greater

spread of fuel throughout the test chamber.

Likewise, a downward spray will allow for lower pressures to be used,

resulting in larger droplets that fall like rain drops through the test cell.

In order to be able to facilitate these

three orientations the pressure vessel has two main design aspects. First, the air line quick connects on both

the top and bottom of the vessel (with the lid securely tightened down) means

that either the top or the bottom can receive the pressurized Nitrogen. This is important since the pressure vessel

can be flipped up to 180° in order to change from a downward to an upward

spray. Having the quick connects on both

sides also keeps one from putting the Nitrogen up through the fuel which could

cause the aeration of some JP-10 particles or the stagnation of Nitrogen

bubbles into the JP-10.

The second important design aspect is the

threaded center hole in the lid of the pressure vessel. This allows for piping to be inserted from

both ends of the hole. Coming out of the

hold through the top of the lid would be a permanent pipe which leads to the

control valve and then to the nozzle. If

the experiment calls for a downward or a sideways spray then this will not be

changed with the lid being on the bottom of the pressure vessel pointing

towards the ground. For these spray

orientations the quick connect mounted in the body of the pressure vessel would

be used to fill the vessel with pressurized Nitrogen. Should the experiment call for an upward shot

a pipe with a length of 18 cm can be threaded into the bottom of the lid. When pressurized the JP-10 will flow up

through this pipe, through the permanent pipe and then through the valve to the

nozzle. In this scenario the quick

connect in the lid of the pressure vessel will be utilized for Nitrogen pressurization. For a sideways spray a 90° elbow will be used

to direct the spray parallel to the ground.

Placing this 90° elbow immediately before the valve should produce results

that would most closely relate to those of the same parameters that lack the

elbow.

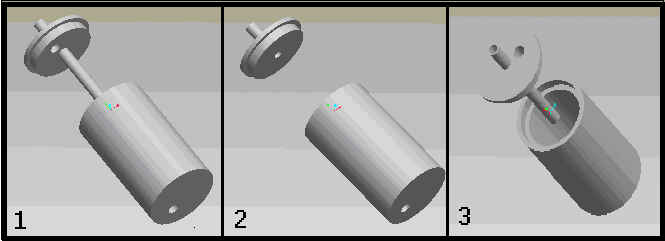

3-D Rendering, Set Up For :

An (1) upward spray (2) downward or sideways shot (3) Different angle for an upward shot

|