|

Test Integration |

|

This section involves the before integration of each component as well as the integration at Eglin Air Force Base.

Before Integration

Sabot

The sabot is largely dependant on the gun barrel that is located at Eglin Air Force Base. The integration of this component into the test space is impossible before the team is able to visit the test site again. The loading of this component into the barrel is an issue that the team and sponsor have explored. The plan is to muzzle load the payload package and use a ram rod in order to push the payload package down the barrel. A small rod will be needed to sit in the barrel on the breech end to provide a stop when the payload package reaches the desired position. The effectiveness of this design will be tested when the components test is integrated.

Whole Completed Sabots

Sphere

The sphere is part of the payload package. It will be cradled by the sabot and then muzzle loaded into the gun tube. The sphere does fit in the sabots determining the effectiveness of the entire payload package will not be scene until the team is able to integrate the test at the test bay. The spheres will also be heat treated before the test, but the testing is outside the scope of the project.

Payload Package Protruding from Gun Tube

Extrusion Block

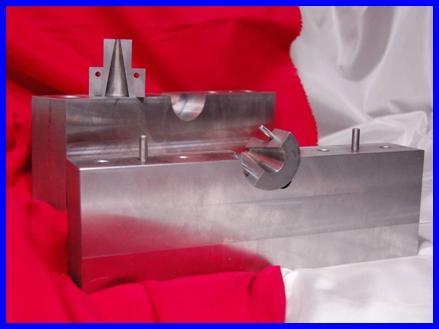

The Finished Extrusion Block

The finished housing is fit exactly to the insert. With the three housings machined, it is the same for each case. After receiving the piece and dry fitting the component, the team made one small modification to the next two being constructed. A pair of jack screws are now located close to the dowel pins in order to allow the top block to be lifted in line with the pins.

The height is also something to consider. The block is 3.75” tall and the height of the flight path is 3.86” tall. This gap will be filled with gasket or cork material in order to absorb vibration. The correct material will be determined when the system is integrated.

Soft Catch

The soft catch is the only component that the team was not truly able to design. The testing apparatus created is only a temporary component that can be used to determine the constants for the mathematical model. Once these constants are found, the equations can be used to design a more accurate soft catch with variable soft catch materials. Although the preliminary tests were done, an environment able to record velocity at different sections as well as time and depth is needed to determine the constants. The gun bay at Eglin Air Force Base is able to do so.

Finished Soft Catch

|

|

Copyright 2006-2007 Famu-Fsu College of Engineering . All Rights Reserved |