|

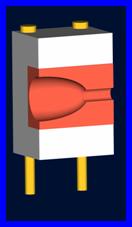

Extrusion Device-Design 2 |

|

After the first brainstorming session, the team met with various members of the FAMU/FSU College of Engineering Mechanical Engineering staff in order to refine the design. Design 2 includes an insert that would contain the extruding cross section. This design would allow for the insert to be removed and be re-machined or an alternate insert to be created if the insert is damaged. The design is clamshell and separates from top to bottom in both the insert and the housing block. The insert is held in place by a square shoulder on each side. The parabolic to cylindrical section remains on this model which is still a concern due to the high stresses. The horizontal mid-plane has a seam separating top and bottom of the housing block and insert.

Pros: The extrusion component can be removed, re-designed and re-machined. The design uses a minimum of high strength material which overall lowers the cost of design. Cons: The channel restricts view of the extruding material which again is the area of interest. The sabot can deflect randomly. More parts exist which means that setup could take longer and be a bit more difficult. Again the extrusion section is not the conical configuration used by Los Alamos

Design 2- Half view cut along the middle line

|

|

Copyright 2006-2007 Famu-Fsu College of Engineering . All Rights Reserved |