|

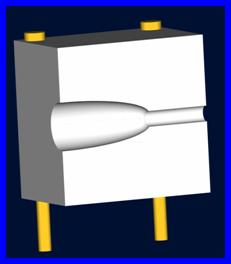

Extrusion Device- Design 1 |

|

Design 1 was the base level of understanding that the team felt would successfully complete the objective. The design is a clamshell design, meaning that the design splits into two symmetric sections. The two sections separate in the vertical direction. A cross-sectional image of the initial concept is shown in Figure 6. The other side of the block would be a mirror image. The purpose of the clamshell design is to retrieve any residual elements of the sphere that are not extruded completely through the block. The design features a parabolic section with an extrusion channel. The region where the parabola meets the cylindrical channel would be a place for high stress and elevated pressure. The block would be held together by steel rods and steel nuts that would hold the extrusion block to the table.

Pros: The design is very simple made of only two identical parts. Because it is only made of two parts, this design would be very easy to set up and use. The machining would not be difficult because the same cuts are duplicated. Cons: The entire test section must be made out of the same material, which has cost implication for purchasing high grade steel. The test section is parabolic and the one used at Los Alamos Research Lab was conical. The parabolic section would be more difficult to machine. There is no precaution taken to where the sabot will go and what it will do. The extrusion channel in the rear of the block obscures the field of view of the extrusion process relative to recording the event with high speed photography.

Design 1-Half view cut along the middle line

|

|

Copyright 2006-2007 Famu-Fsu College of Engineering . All Rights Reserved |