|

This section describes the design elements we needed to define in order to produce a physical working model. |

|

Design Elements |

|

This is our proposed design concept for mixing. The reactor tank will be pump mixed through a system of pipes outside of the reactor. |

|

Design Element 1: Mixing |

|

Hoppers will be used to eliminate the handling of chemicals. |

|

Design Element 2: Hoppers |

|

Ideally we would like to utilize a biodiesel generator to produce the biodiesel. We have calculated that we would only need to use 5-10% of our biodiesel produced to run the generator. Therefore this method is preferred. |

|

Design Element 3: Power |

|

To heat the reactor tank to the reaction temperature, we will use immersion heating elements that will be in direct contact with the reactor fluid inside the reactor. We will use a thermocouple to monitor the fluid temperature. |

|

Design Element 4: Heating |

|

Eglin 1—Team 12: Biodiesel Plant |

|

The methanol recovery is a unique component of our system. The main goal is to recover some of the methanol that is vaporized during the reaction process. |

|

Design Element 5: Methanol Recovery |

|

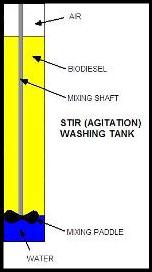

This washing method was chosen because it will tell us whether or not our reaction was complete. When the water and fuel are mixed, they should separate if there is a complete reaction. If the reaction was not complete, they will not separate. |

|

Design Element 6: Washing |