|

System Walkthrough |

|

Eglin 1—Team 12: Biodiesel Plant |

|

The first stage of the biodiesel manufacturing process is the chemical mixing and reactor stage. The chemicals are mixed in the methoxide mixing tank which is located above the reactor tank. The oil is preheated to 55˚C and the chemicals are added by opening the valve between the tanks. The chemicals are gravity fed into the reactor. The reactor is heated by two heating elements, and the fluid inside is mixed using a pump. The pictures below show these components of the system. |

Chemical Mixing / Reactor Stage |

Glycerin Separation |

Washing Stage |

Transfer System |

Methanol Recovery |

|

After the reaction is complete and the fluid is allowed to settle, a layer of glycerin forms on the bottom of the reactor barrel. The glycerin must be removed from the system. If it is left in the biodiesel, it could significantly damage an engine using the fuel to operate. The glycerin is gravity drained into the glycerin holding tank. One of the reasons we used clear piping was so we could see when the glycerin had completed draining. |

|

Once the glycerin is removed from the system, the biodiesel needs to be washed. This washing happens in a separate tank. Washing simply means removing the impurities and particulates from the biodiesel. The biodiesel is transferred to the wash tank where water is added. For our 20 gallon batch of biodiesel we added about 10 gallons of water to wash it. The water is mixed with a paddle mixing blade attached to a drill until the water is completely mixed with the fuel. Then the water is allowed to settle to the bottom of the tank taking the impurities with it. One was is not enough so we repeat the process two more times. Each time, the fuel should get lighter and lighter. The lighter the fuel, the cleaner it is. The picture below shows the wash tank with the drill on top. |

|

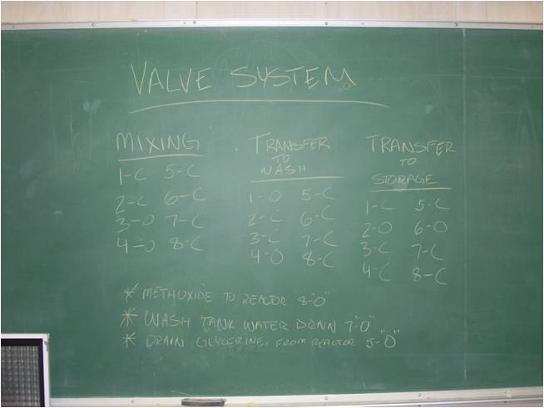

Our biodiesel plant employs an ingenious system for transferring and mixing fluids. Instead of using the three pumps we had originally planned on using, we combined all of our mixing and transfer systems into one, compact, money saving system. We no longer needed to pay for three pumps, but instead only one. This was a major achievement for our group. All valves in our system are numbered, and the first picture below shows the guide we used to tell us which valves should be open or shut for each part of the experiment. The second picture shows a few of these valves close to the pump. |

|

One unique part of our plant that many biodiesel plants do not use is a methanol recovery system. This system utilizes an air compressor driven vacuum pump that pulls methanol vapor away from both the glycerin storage tank as well as the reactor tank. The vapor is pulled through a simple heat exchanger filled with ice water where the methanol condenses and drains into a methanol storage tank. The picture below shows this system. |