The physical properties of composites are fiber dominant. This

means that when resin and fiber are combined, their performance remains

most like the individual fiber properties. For example, it is not

satisfactory to merely average the tensile strengths of fabric and resin to

determine the strength of a panel. Test data shows that the fibrous

reinforcement is the component carrying the majority of the load. For this

reason, fabric selection is critical when designing composite structures.

The average fabricator has a choice of three types of

reinforcing materials with which to construct a project. These are

fiberglass, carbon fiber, and Kevlar®. All three have their benefits and

shortcomings, and are available in numerous forms and styles.

To

understand composites, there are some key terms that must be understood. The finished product is referred to, so

eloquently, as the piece. The item constructed in the mold is

called the plug. The mold

is the basis for the manufacturing of the part. There are two types of molds; male and

female. Male molds are

the actual shape of the intended piece and female molds are the negative

space that the piece could be formed in. A laminate is the solid part

constructed from a combination of resin and reinforcing fabric. This

also refers to the process, i.e.

laminating. The gel coat,

also known as the surface coat, is a term that technically

applies to polyester-based materials. The term surface coat is

used to describe epoxy or polyester materials that are thickened formulas

of resins which can be used on the surface for cosmetic and protective

reasons. Release

agents are chemicals added to the surface of the mold to help the

release of the part from the mold (Fiber Glast).”

Glass fiber, commonly called fiberglass, is a versatile

and relatively inexpensive composite material. It is the most widely accepted and least expensive reinforcement.

It has been used successfully in many applications since the 1950’s, and

much is known about its properties. It is relatively lightweight, has

moderate tensile and compressive strength, is tolerant of both damage and

cyclical loading, and is easy to handle and machine. Because it is considerably cheaper than carbon fiber

and Kevlar, fiberglass cloth is more widely used in industry (Fiber

Glast).

Carbon

Fiber

The

idea of carbon fiber first came to life when Thomas Edison took out a

patent for the manufacture of carbon filaments for use in electric lamps. Commercial production of this product was

not started until the early 1960’s by Royal Aircraft Establishment at

Farnborough, Hampshire in England. Recently applications of carbon fiber

have been extended to products in numerous industries such as sporting,

transportation, and manufacturing.

Improvement in materials, technologies and customer awareness are

allowing for carbon fiber to be produced at a steadily decreasing price.

The product itself is generally the same in its

composition, and only varies in the care taken to create it as well as its

quality of carbon. Its atomic structure is very

similar to graphite, where it is basically sheets of carbon which are in a

hexagonal shape, but instead of being in parallel with each other as in

graphite, the hexagons of carbon are chaotically strewn together, making the

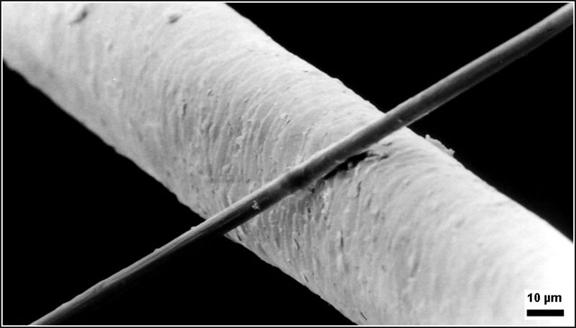

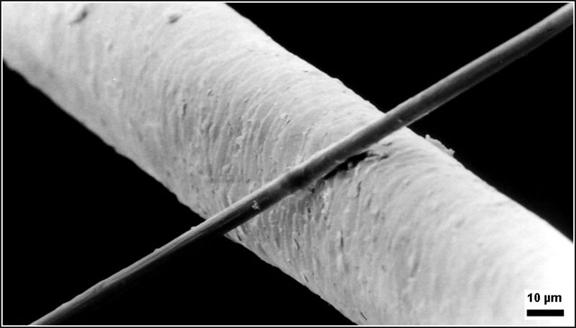

end product much stronger and more flexible (see Figure 3.1). A carbon

filament is a thin tube with a diameter between 5 – 8 microns. The fibers have high electric

conductivity and low thermal conductivity.

Figure 3.1: Hexagonal Structure

(James)

Carbon

filaments are commonly made by using oxidation and thermal pyrolysis on polyacrylonitrile

(PAN). This is a

polymer which when heated under the correct conditions, most of the

non-carbon contaminants evaporate away. The result after drawing is a filament

which is 93-95% carbon. Lower quality

filaments can be made by using pitch or rayon instead of PAN. Figure 3.2 shows a strand of carbon fiber

as compared to human hair.

Figure

3.2: A 6 μm diameter carbon filament

compared to a human hair. (Carbon Fibre)

Kevlar

Kevlar

was developed in 1965 at the Dupont Company by

Stephanie Kwolek by synthesizing two monomers and

drawing the solution into a fiber. Kevlar is commonly used as reinforcement

in marine and aviation industries. Kevlar has become most famous for its

military applications. It is used in body armor, gloves, helmets, vehicles,

and many more applications. Military body armor was previously made from heavy metals

and ceramics. The Kevlar used

in the new Interceptor Outer Tactical Vest is five times the strength of

steel by weight. This weight

reduction drastically increases a soldier’s mobility and decreases human fatigue. Kevlar has become such an integral part

of the military that many soldiers refer to their Kevlar helmets as “my

Kevlar.” Kevlar has a

tensile strength of 3GPa. (Kevlar).

Comparison

Table 3.1 shows comparative

properties of Glass Fiber, Carbon Fiber, and Kevlar.

Table 3.1: Materials Properties

|

Property

|

Glass

Fiber

|

Carbon

Fiber

|

Kevlar

|

|

Fabric

Density (g/cm^3)

|

2.5

|

1.78

|

1.44

|

|

Tensile

Modulus (Mpsi)

|

2.5

|

8.2

|

3.8

|

|

Tensile

Strength (kpsi)

|

45.8

|

75.6

|

45.4

|

|

Flexural

Modulus (Mpsi)

|

3

|

6.4

|

2.5

|

|

Flexural

Strength (kpsi)

|

66.7

|

96.5

|

34.5

|

Polyester

Polyester resin is a commonly used substance

because of its flexibility in use and its wide variety of

applications. This product is

commonly available at retail stores for use with fiberglass. In most polyster

resins a catalyst such as Methyl Ethyl Ketone

Peroxide (MEKP) is added to begin curing. Many professionals use polyester

resins because of their low viscosity.

This makes them easy to handle and infuse (Fibre

Glast).

Epoxy

Epoxy

resins are not as versatile as polyester resins and must be used with

greater care. However, some say that

epoxies provide a superior part. In

many tests, epoxy resins made a tougher part allowing it to absorb more

energy before failure. Epoxies are usually more expensive and are viscous

making them difficult to work with and even more difficult to infuse (Fibre Glast).

Vinyl Ester

Vinyl

ester resin qualities lie between those of polyester and epoxy. Its most important characteristic is

corrosion resistance. For this reason, vinly

esters are commonly used in boat hulls, fuel tanks, and chemical storage

tanks. The most important drawback

to vinyl ester is its short shelf life of about 90 days (Fibre Glast).

Resin

Transfer Molding

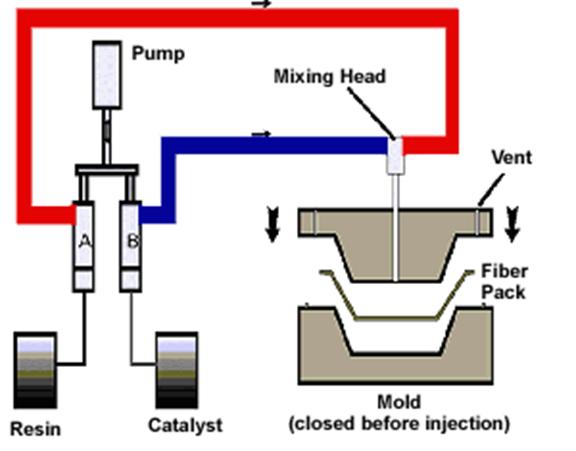

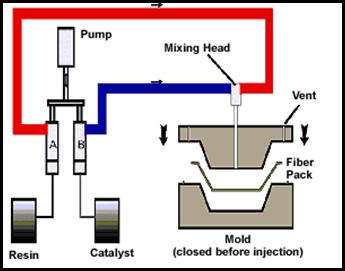

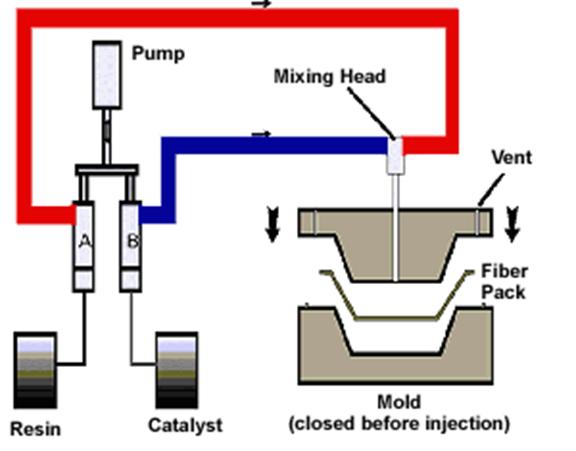

Resin

Transfer Molding (RTM) is a process by which reinforcing fiber is held in a

closed mold at room temperature and atmospheric pressure. Resins are injected into the mold via

injection ports. Air and excess

resin escape the mold through vents. This process provides a smooth, defined

finish on both sides of a part. Resin Transfer Mold provides

a part with very few voids and consistent resin concentration. In common applications, the reinforcing

material is glass fiber and the resin is an epoxy that is a mixture of a

resin and a catalyst. Figure 3.3 is a

basic diagram of the process.

Figure 3.3: (Resin Transfer Molding)

In

order to control resin and make a smooth part, materials can be placed

inside a plastic bag to which a vacuum is applied. This removes air from the part making a

very low void ratio (air in the product). It also holds the material

tightly against the mold making the part very smooth on both sides (Vacuum

Bagging).

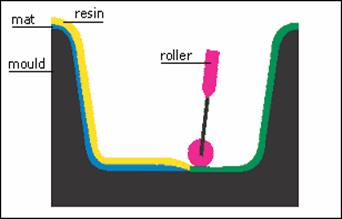

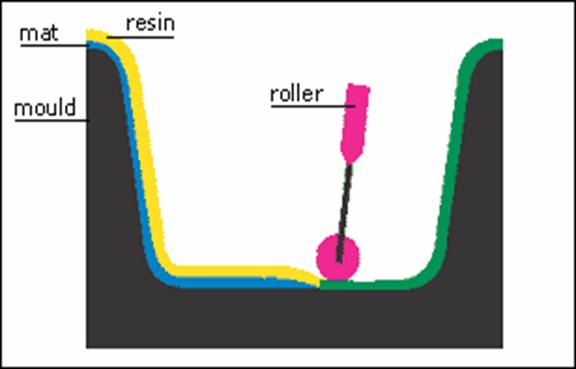

Contact

Molding

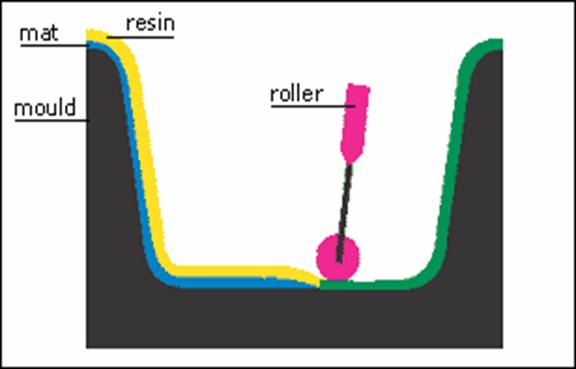

Contact molding is commonly

known as hand lay-up. In this process, a mold is layered with various

materials to produce the product. Then using a roller press or a brush, the

material is pressed to form one component as shown in Figure 3.4. Examples of applications are plane wings,

motorboats, and train noses such as Figure 3.5 (Hand Lay Up

Process).

Figure 3.4: Hand Lay-Up

Process (Hand Lay-Up Process)

Figure 3.5: Bullet Train (Hand

Lay Up Process)

Oven

The ovens used in composite manufacturing work on the

same principles as a household baking oven. These ovens cure composites at high

temperature and a pressure of 1 atmosphere. The composites lab available to students

has an oven with 12 cubic feet of heated space.

The most common use of autoclaves is the

sterilization of surgical and scientific instruments. They operate at high temperature and high

pressure. The temperature and pressure can be varied to achieve the

engineer’s desired results. The composites lab available to students does

have a large autoclave but the facilities have prohibited its set-up and

projects have not deemed its connection necessary. Thus, the autoclave is not set up or

connected to any of its needed systems and is not available for the group’s

use.

Many composites can be cured at room temperature. This process is simple, inexpensive, and

is capable of producing very strong parts. Parts may take longer to cure but in

many cases this is preferred to the costs of owning and operating large

ovens and autoclaves.