Note: These processes are

described in detail with photographs and drawings in the instruction

manual.

The

male mold form was provided by the sponsor. This was created in a rapid

prototyping machine and coated with epoxy to seal it. In many cases in

industry, mold forms and molds are machined from metals or polymers. Though the group has access to a five-axis

Computer Numerical Controlled (CNC) mill at the composites lab, there are a

few downsides to machining and using these materials. These materials are very expensive. For example, a bar of aluminum 2.25’’

square and 36’’ long to make this form would cost the group $170.75

(Speedy Metals). Also the group has to wait weeks for these materials

to ship. If a machining

error occurred, the loss would be great. This led the group to make molds out of gypsum plaster,

which is far less expensive and more readily available. The mold box was made from particle board

5’ x 10’ sheets 3/4” thick. This was used

because of its availability, consistency, and workability.

All

of the wood was sprayed with Minwax Polycrylic polyurethane. This was used because it provides a

smooth, durable finish, with less than one hour recoat times and simple

water cleanup. The coating was

sprayed with an automotive style spray gun for optimum volume and coverage

control. Also, the

coating is much more affordable to purchase in bulk than in individual

spray cans. The box was assembled

using #8 X 1” sheet metal screws throughout and labeled to ensure proper

and easy assembly and disassembly.

After disassembly, each piece was waxed with paste

wax. This wax, commonly used on furniture, was used to seal and level any

small imperfections as well as ensure proper release of plaster castings. With

a center line drawn on the mold form, the mold form and box were

assembled. The bottom half of the

mold was poured and allowed to cure.

After leveling a waxing the bottom of the mold, the top half was

poured. After careful separation of

the molds, the corners were rounded with sandpaper. The molds were cured in

the oven for 24 hours and then wax was applied to the warm molds.

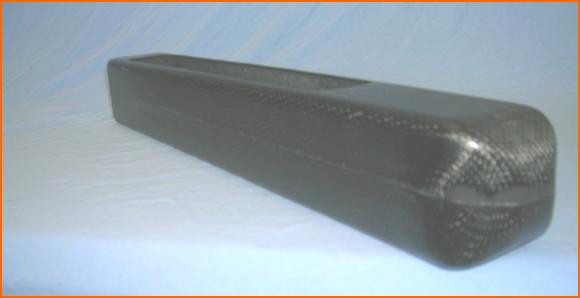

Figure 7.1: Molds

The

plaster mold was coated thoroughly with paste wax to keep resin from

leaching into it. The wax was

allowed to dry for five minutes between coats and was buffed lightly after

the final coat. The area of the mold

where the cloth is laid was coated with Poly Vinyl Alcohol (PVA), a water

based release agent. The PVA was allowed

to dry for 15 minutes. The first

layer of carbon fiber was laid and formed into the mold. The excess was then trimmed. The mold was sprayed with a common spray

adhesive to hold the cloth in place.

This step does not bond the cloth to the mold. It temporarily bonds the cloth to the

layer of PVA release agent.

Subsequent layers of the cloth were trimmed and bonded to previous

layers. A layer of peel ply was placed

on top of the final layer of cloth.

This material keeps the flow media and vacuum bag from being bonded

to the carbon fiber. A layer of mesh

flow media was placed over the peel ply.

This media allows the resin to flow quickly and evenly into the

cloth. If the peel ply is not

positioned correctly, the flow media will permanently bond to the carbon

fiber thus ruining the part.

The

part was covered in a polymer sheet that is sealed with vacuum bagging

tape. Inlet and outlet tubes were

sealed into the bags. The ends of

the tubes were covered with a small piece of flow media to keep the bag

from stopping the flow. The inlet

tube was crimped with locking pliers.

The outlet tube was connected to a vacuum chamber. The vacuum chamber was connected to a

vacuum pump. This chamber is used in

case any resin flows into the vacuum hose.

Cured resin is easily cleaned from a vacuum chamber. A small amount of resin would ruin a

vacuum pump that easily costs thousands of dollars. Once proper vacuum is established, resin was

allowed to enter the inlet and infuse the part. When the part is completely infused, the

inlet and outlet are closed. The part was allowed to cure for 18

hours. The part was then removed

from the mold. The part was trimmed

with a diamond blade saw and the edges were sanded. The cap parts and

bonding strips were cut from a flat sheet of infused carbon fiber using the

water jet machine. Also the top

opening and vent in the fuselage pieces were cut using the water jet. The parts were lightly sanded, and the

fuselage was bonded together. The

completed fuselage was coated lightly with Minwax

Polycrylic to seal and protect the shell.

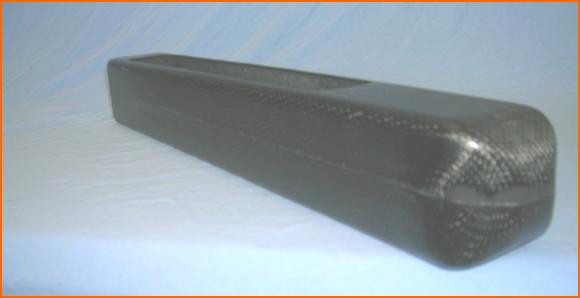

Figure 7.2: Fuselage (Iso)

Figure 7.3: Fuselage (Top)

Figure 7.4: Fuselage (Bottom)

Motor Mount Plate

In order to cut the motor mount plate, the aluminum was

secured in the water jet machine. The

drawing exchange file was loaded and the part was cut. The part was painted black to promote

military tactical advantage and was then bonded to the fuselage.

Figure 7.5: Motor Plate