The first fuselages were built with a four part

design as in the Bullwinkle 1 model. This model was very strong and

aerodynamic. The first prototype was constructed with 3k plain weave carbon

fiber. “3k” means that each strand consists of 3,000 fibers of carbon. This

fabric was easy to work with but the loose weave left a porous surface in

the fuselage even with two layers.

The vinyl ester resin worked well in conjunction with the vacuum infusion

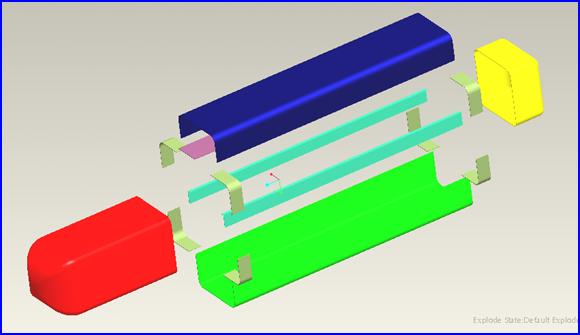

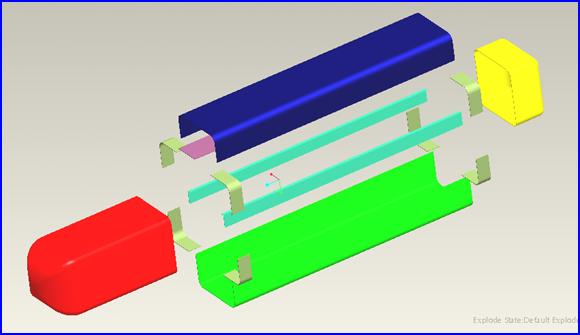

process as the research suggested it should. Figure

5.1 shows the final design of the parts of Group 15’s first

Bullwinkle. In this model the three

parts of the main structure are held together with bonding strips cut from

excess material from the lay-up process.

The parts were allowed to cure at room temperature for 18 hours and

were bonded together with epoxy.

Figure 5.1: Original Design

At beginning of the fall semester, the team

constructed the same design from a different type of carbon fiber cloth.

This new material was tight 3k twill weave material. As opposed to the plain weave, light did

not pass readily through even one layer of this material. This new material

increased the weight to around 130 grams.

This made the fuselage heavier, but close

enough to the specifications to be approved by the sponsor. It also allowed

for a much more aerodynamic and stronger structure.

With an elementary knowledge of composites, the group

looked for other ways to improve the design. The team evaluated laying up

the whole structure at one time. As

it sounds, this was very difficult, and was quickly abandoned. The best fuselage design was constructed

in two main parts instead of four, which was an appropriate compromise of

the previous ideas. After bonding,

the fuselage is a complete shell with cutouts. The process is still the same but the

fuselage is much stronger and requires much less secondary labor. In the original design, the group

required about ten man hours of labor to make a complete fuselage after the

main parts were infused. This work

is known as secondary labor. With

the final design, the secondary labor is cut to about 1 hour.

The final design used the 3k twill weave carbon fiber

material. This material was infused

with vinyl ester resin through the vacuum infusion process. The molds were

female plaster molds as they have worked well throughout this project. The main design difference was the shape

of the parts. The structure of the

fuselage was made from two main parts. All the other parts were cut from a

flat infused sheet of carbon fiber.

A major area of time saving was the method of cutting. All of the flat pieces and the openings

in the fuselage were cut using the water jet cutter. This provided extremely quick and

accurate cuts that needed only minimal sanding. The bonding material was changed from JB

Weld epoxy to a two part, five minute epoxy, available at most stores. Carbon fiber dust (made from sanding) was

added to the clear epoxy for color.

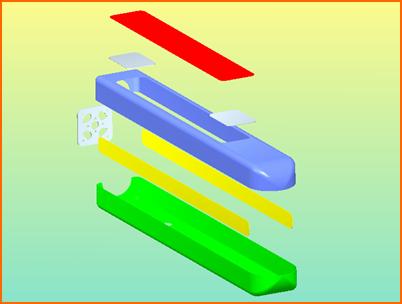

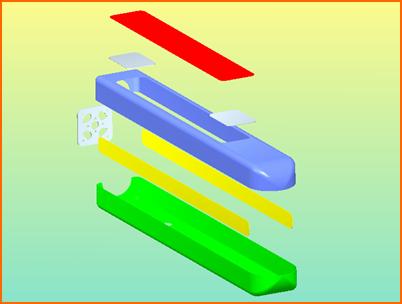

Also, in the spring semester, Group 15 designed and

built motor mount plates. The plates

were designed on a sketch program called Omax

Layout. The plates, designed to

promote air flow through the motor, were cut from 0.064” thick 2024

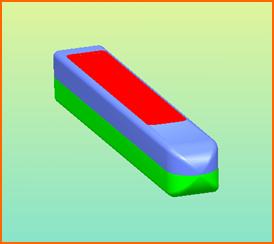

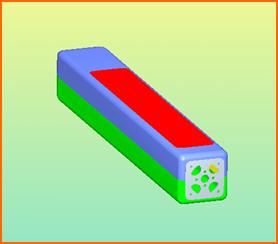

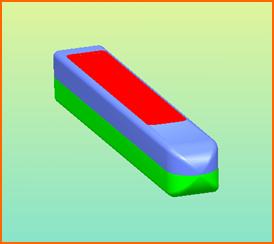

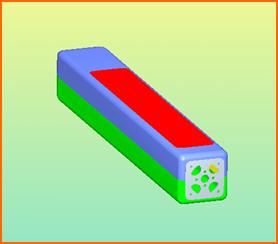

aluminum. Figures 6.1, 6.2, and 6.3

show renderings of the final fuselage design.

Figure 6.1: Final Design Explosion

Figure 6.2: Final Design

(Isometric) Figure 6.3:

Final Design (Rear Isometric)