Manufacturing Research

Materials

Glass Fiber

Glass fiber, commonly called fiberglass, is a Versatile and Relatively Inexpensive Composite Material. To understand fiberglass, there are some key terms that must be understood. The finished product is referred to, so eloquently, as the piece. The item constructed in the mold is called the plug. The mold is the basis for the manufacturing of the part. There are two types of molds; male and female. Male molds are the actual shape of the intended piece and female molds are the negative space that the piece could be formed in. A laminate is the solid part constructed from a combination of resin and reinforcing fabric. Also refers to the process, i.e. laminating. The gel coat, also know as the surface coat. Gel coat is a term that technically applies to polyester-based materials. The term surface coat is used to describe epoxy or polyester materials that are thickened formulas of resins which can be used on the surface for cosmetic and protective reasons. Release agents are chemicals added to the surface of the mold to help the release of the part from the mold. The last term discussed will be the parting dam or flange. This tool “creates a surface for materials to be molded against, perpendicular to the parting plane of symmetry. The flange aids in clamping or bolting the mold sections together, as well as serving as a mounting point during vacuum bagging operations.”

Because it is considerably cheaper than carbon fiber and Kevlar, fiberglass cloth is more widely used for. “Fiberglass cloth comes in a wide variety of styles and weights, making it ideal for many applications. High-strength weave styles are available, and these could be considered cost effective alternatives to the advanced fabrics” (Fiber Glast).

Kevlar

Kevlar was developed in 1965 at the Dupont Company by Stephanie Kwolek by synthesizing two monomers and drawing the solution into a fiber. Kevlar is commonly used as reinforcement in marine and aviation industries. Kevlar has become most famous for its military applications. It is used in body armor, gloves, helmets, vehicles, and many more applications. Military body armor used to be made from heavy metals and ceramics. The Kevlar used in the new Interceptor Outer Tactical Vest is five times the strength of steel by weight. This weight reduction drastically increases a soldier’s mobility and decreases fatigue. Kevlar has become such an integral part of the military that many soldiers refer to their Kevlar helmets as “my Kevlar.” Kevlar has a tensile strength of 3000MPa. It is very light but is heavier than fiberglass and carbon fiber (Kevlar).

Carbon Fiber

The idea of carbon

fiber first came to life when Thomas Edison took out a patent for the

manufacture of carbon filaments for use in electric lamps. Commercial production of this product was not

started until the early 1960’s by Royal

Aircraft Establishment at Farnborough, Hampshire in

The product itself is generally the same in its composition, and only

varies in the care taken to create it as well as its quality of carbon. Its atomic structure is very similar to

graphite, where it is basically sheets of carbon which are in a hexagonal

shape, but instead of being in parallel with each other as in graphite, the

hexagons of carbon are chaotically strewn together, making the end product a

lot stronger and more flexible. A carbon

filament is a thin tube with a diameter between 5 – 8 microns. The fibers have high electric conductivity and

low thermal conductivity.

Figure 2: Hexagonal Structure (James)

Carbon filaments are commonly made by using oxidation and thermal pyrolysis on polyacrylonitrile (PAN). This is a polymer which when heated under the correct conditions, most of the non-carbon contaminants evaporate away. The result is after drawing is a filament which is 93-95% carbon. Lower quality filaments can be made by using pitch or rayon instead of PAN.

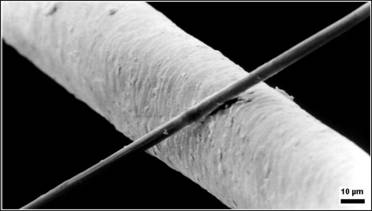

Figure 3: A 6

μm diameter carbon filament compared to a human hair. (Carbon Fiber)

Resin

Polyester

“Polyester resin is a

general-purpose resin suitable for a wide variety of applications. Methyl Ethyl

Ketone Peroxide (MEKP) must be used as the catalyst to

begin the curing process. Catalyzation rates can be

varied with polyester resins and environmental conditions. In thin laminations

or when gel coat is sprayed as a topcoat, the surface may remain tacky and not

cure properly if left exposed to the air. To get a complete cure, thin

laminations or top coats must contain either styrene wax solution of have a

coat of polyvinyl alcohol (PVA) solution sprayed over them to seal out the air”

(Fiber Glast).

Epoxy

“Epoxy resins are not as forgiving in their measurement as polyester resins, but epoxies provide a greater part strength and dimensional stability. They also adhere to other materials better than polyester resins. Epoxy hardener ratios can’t be varied, and adequate temperatures (at least 70 degrees F) must be maintained during the curing process. Epoxy resin systems tend to cost more than polyester resins, but they are a virtual necessity in some repair applications, such as with Sheet Molded Compound (SMC). Epoxy resins are also highly recommended for use with Kevlar® and carbon fiber” (Fiber Glast).

Vinyl Ester

“Vinyl ester possesses qualities that fall between polyester and epoxy resins for the most part. It excels above both, however, in the areas of corrosion resistance, temperature resistance (it’s good to 300 degrees F), and toughness. Common uses include boat hull repair, full tank construction and chemical storage tank linings. Like polyester resin, it is catalyzed with MEKP, but vinyl ester has as shorter three-month shelf life” (Fiber Glast).

Bonding Processes

Resin Transfer Molding

Resin

Transfer Molding (RTM) is a process by which reinforcing fiber is held in a

closed mold at room temperature and atmospheric pressure. Resins are injected into the mold via

injection ports. Air and excess resin

escape the mold through vents. This

process provides a smooth, defined finish on both sides of a part. Resin

Transfer Mould Provides a part with very few voids and consistent resin

concentration. In common applications,

the reinforcing material is glass fiber and the resin is an epoxy that is a

mixture of a resin and a catalyst.

Figure 4 is

a basic diagram of the process.

Figure 4 (Resin Transfer Molding)

Vacuum Bagging

The concept of vacuum bagging is to place the object in construction in an airtight bag and then remove the air from it creating an airtight seal around the product. Some of its uses include wrapping items for storage and transport, creating a tight seal around products in which the chemicals of the process must not escape, and laminating products. Some of the pros for this process is an unnoticeable increase in weight, the bag is evenly distributed which in turn increases strength and durability (Vacuum Bagging).

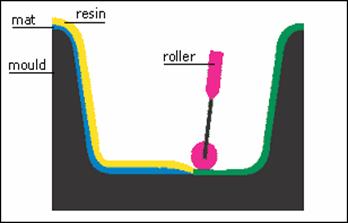

Contact Molding

Also called hand lay-up, in this process, a mold is layered with various materials to produce the product. Then using a roller press, the material is pressed to form one component as shown in Fig 1. Or perhaps before the product is finished, more layers are added after the initial set of layers dry.

Figure

5 (Hand Lay Up Process)

The main ingredient is resin, which promotes adhesiveness and rigidity. Products of any size can created through this process however, it is a timely process. Examples of applications are plane wings, motorboats, and train noses such as Figure 6 (Hand Lay Up Process).

Figure 6 (Hand Lay Up Process)

Curing

Autoclaving

An autoclave is a device that sterilizes an item at values of high pressure. Some examples are needles and surgical instruments. An autoclave could possibly be used in the space industry where the parts and components need to be as sterile as possible (Autoclave).

Room Temperature

Many composites can be cured at room temperature. This process is simple, and inexpensive and is capable of producing very strong parts.

References

“Autoclave” 2007. Lexico

Publishing Group, LLC 10 October 2007 www.dictionary.com

“Autoclave” 14:24, 8 Oct 2007 Wikipedia 10 October 2007 http://en.wikipedia.org/wiki/Autoclave

"Autoclave." Encyclopædia Britannica. 2007 Encyclopædia Britannica Online. 10 Oct. 2007 <http://www.britannica.com/eb/article-9011357>.

“Carbon Fiber.” http://en.wikipedia.org/wiki/Carbon_Fibre (7 Oct 2007).

“Carbon Fiber Guide.” http://www.asbury.com/pdf/CarbonFiberGuide.pdf (June 2003).

“Fibre Glast Developments.” 10 October 2007. http://www.fibreglast.com/contentpages-molding+fibreglass-171.htm

“Growth opportunities in Carbon Fiber Market 2006-2011.” http://www.e-composites.com/marketcarbon.asp (November 2006).

“Hand Lay Up Process” 1996-2004 Design Insight ©1996-2007 10 October 2007 http://designinsite.dk/htmsider/p0102.htm

“Hex Tow Carbon Fiber Selection Guide.” http://www.hexcel.com/NR/rdonlyres/ 225E3CA5-965B-4B29-9A920CE184B1DDF3/0/CarbonFiber_ SG_US.pdf (June 2007)

James, Mathew. “An Introduction to Carbon.” http://www.chm.bris.ac.uk/webpro jects2002/mjames/carbon.html (15 June 2002).

“Kevlar.”2007. www.kevlar.com Accessed: 2 Oct 2007.

“Resin Transfer Molding,” JHM Technologies, inc.

www.rtmcomposites.com/whatrtm.htm2005 Accessed 5 Oct 2007.

Tomba. “Carbonfibre.” http://www.f1technical.net/articles/3 (21 Sep 2002).

“Vacuum Bagging” 21 September 1996 Chris Fouquet 10 October 2007 http://www.pilotsguide.com/rc/vacbag.shtml