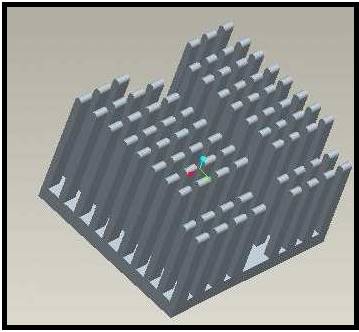

Finned Heat Sink Model

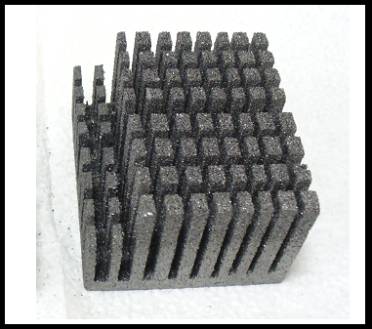

Finned Heat Sink Prototype

Prototypes

Prototype I: Finned Heat Sink

Carbon foam will be investigated for use as a thermally conductive material. A carbon foam heat sink will be tested and compared to an identical one made from a conventional heat transfer material (aluminum). Heat sinks absorb heat from electronic components by thermal conduction. The heat travels through the fins of the sink, and is dissipated to the environment by convection.

|

Finned Heat Sink Model |

Finned Heat Sink Prototype |

Prototype II: Flow Injection System

It was decided that another model should be designed; one that improves upon the performance of the finned heat sink.

Prototype II is a cylindrical model with a tube inserted into a hollow section in the middle. Air is injected into the middle of the cylinder. The flow travels radially through the pores, carrying heat away. This takes advantage of the high porosity of carbon foam. The mode of heat transfer for this design is conduction from the processor to the carbon foam and convection from the carbon foam to the ambient air. Heat transfer by convection is directly proportional to the internal surface area, which is related to the porosity of the foam.

|

Flow Injection Model |

Flow Injection Prototype |