|

Rancho Suspension Senior Design |

|

Team 7 |

|

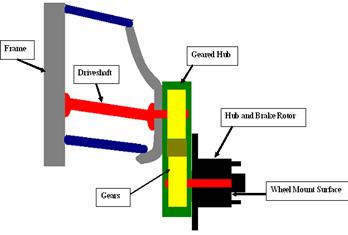

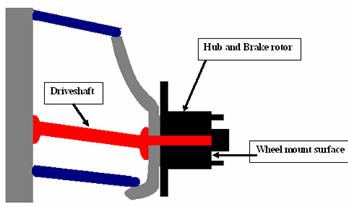

These pictures show the replacement of the stock hub design with the new geared hub design. |

|

Project Objective |

|

COE Machine Shop rm.102 2525 Pottsdamer Tallahassee, FL. 32310

Phone: 850-410-6210 |

|

In the off-road and aftermarket suspension industry, the basic lift kit is a tool used by many in order to get stock trucks to perform beyond specifications. The “typical” consumer likes the idea of making his/her truck perform better and being able to take it unexpected places. Although the “typical” consumer likes this idea, he/she does not like the idea of spending a lot of money to do this.

The 2007 TRD Toyota Tundra is the “biggest and best” ½ ton truck currently on the market, and is a truck that consumers want to take advantage of in more aspects; case in point, off-road exploring and aftermarket lifting. The stock Tundra comes with the strongest components for suspension, braking, chassis, etc. The problem that deters numerous customers from modifying the Tundra with a standard lift-kit is that cutting, welding, and other forms of serious modification to the stock truck are necessary to get the desired effect. What is more desired for the customer and in turn more desired for Rancho-Tenneco is a “simple” suspension modification that lifts the truck a certain distance without needing all new components, hence keeping the truck more of a stock vehicle with higher ground clearance, and keeping the price tag down. The solution to this problem is to implement the use of a geared hub design (portal box) replacing the stock knuckle with the new design which increases the ride height of the vehicle with no major fabrication/ frame medication. The pictures to the right, give a simple description of this new hub design. |

|

To contact us: |