|

Confinement System for the CRUSHED Experiment |

|

Senior Design 2010-2011 Group #4 |

|

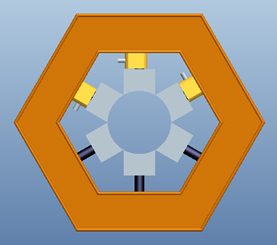

The final design that we came up with was the ring metntioned in concept generation except with a few tweaks to the system. Due to budget constraints the new system will only have three hydraulic cylinders, and the rest of them will be replaced with columns. This was a very effective way to keep cost down and still get the same amount of force out of fewer cylinders. Due to equal and opposite forces this design will apply the same amount of pressure although with less flexibility to get the pipe into the ring. That was the main design change when it came to manufacturing the entire system. All of the cylinders will actuate at once because they are tied into the same pump using a 6-port manifold. These are the main changes that can be seen from the our final design in the concept generation stage to the final design after fabrication. Pictures can be seen below of our final system.

With this final design there is a correlation between the pressure in the hydraulic hose and the pressure on the pipe. The relation is that the pressure in the hose is 9.425 times higher than the pressure on the pipe. With this relationship you are able to caclulate the pressure on the pipe with touching the pipe. Two tests were run on the system to verify these results. The first test was to place a copper wire around the pipe and squeeze it to see how unifor the pressure is. As suspected the gaps in the aluminum blocks were a problem and became large stress concentrators on the copper. Once you get away from the gaps though the pressure is very uniform over the rest of the aluminum block. The second experimant that was run we put a strain gauge on the inside of our test pipe and ran tests at various pressures to see if our equation for the stress was correct. In the graph seen below on one of the tests there was a much larger pressure calculated on the pipe than anticipated, this is believed to be due to the stress concentrations of the corners of the aluminum blocks. While other tests showed that the correlation was very close to the estimated value by the equation above. We believe that this was the best design to chose and that it performed very well and could be made a little bit better with parts machined to a lower tolerence.

|

|

Programming Flow Chart |