Rotational Compressor Valve

Rotational Compressor Valve

EML-Senior Design- Spring

2012

Team 18

Alejandro Castro

Sam Leuthold

Andrew Borger

Department of

Mechanical Engineering, Florida State University, Tallahassee FL

Project Sponsor

Project Advisor:

Dr. Van Sciver

Department of

Mechanical Engineering

Project

Scope

Problem Statement

Current gas compressor intake and exhaust valves restrict flow,

which cause inefficiencies within the system. The currently accepted valve is a

plate valve. The problem with these valves is that the gas must flow around the

plate rather than taking a more direct efficient path. This causes a

restriction of mass flow both coming in and out of the cylinder and the

addition of unwanted heat to the gas. A better flowing valve is needed. The

main proposed solution is a valve that rotates to allow for flow. A mode of

rotating the valve is needed.

Justification/Background

The project focuses on improving the valve design used in GE gas

compressors. These compressors are used all over the world to compress gases

for either transportation or storage. They are piston type units that operate

on a dual stroke cycle that uses the piston to compress gas on each forward and

backward stroke. Each side of the piston requires two sets of valves, one for

intake and one for exhaust.

Currently, GE compressors utilize a plate type valve for this

application. A plate valve is a valve that is activated by a pressure

difference that pushes against a specified spring force for the given

compressor. The pressure difference at which the valve opens can be changed

using different spring rates. As the pressure acts on the sprung plate, the

plate is pushed forward, opening the valve and allowing the fluid to pass

around the plate. While this design is relatively cost effective and is very

reliable, it does not flow very efficiently due to the fact that the fluid must

pass around the plate, which is not a very direct flow route.

In order to maximize efficiency of the compressor, it is important

that the valve design has as high flow as possible. During each stroke of the

piston, the valve creates a minor loss in the flow of fluid into the cylinder.

A restrictive valve limits the flow into the cylinder, which forces the

compressor to go through more cycles to pump the same amount of gas. A better

flowing design can be created using a more direct flow path that would increase

the overall efficiency of the pump by limiting the pumping losses of each

compressor cycle.

Objective

One objective is to find a means of operating, designing, and

producing a rotational compressor valve. This valve should be able to flow gas

into and out of a GE compressor more efficiently while being completely

leak-tight. The new valve design must be adaptable to current GE compressors

and should be cost effective. The new design must also be at least as reliable

as existing designs in order to limit compressor down time during maintenance.

Methodology

To begin deciding what aim we will be taking for the project we

will first analyze and understand the products that are already available. Once

we know what valves are currently being used in the field, we can research the

problems these valves currently posses.

It is also important that the gas compressor that the project is

focused is well understood. This is critical to designing the valve towards the

applications parameters. Some of these parameters are operating pressure, size

of the valve necessary to fit the seat, and operating temperatures.

Once the style of valves already available, their weaknesses, and

the compressor in which the valve will be fitted for are known, we must decided

in which manner we plan to have the valve operating. Each type of operation has

its pros and cons. Though some may have a more reliable operation short term,

they may not have long life times.

Along with the type of valve operation, we must analyze the amount

of flow rate achieved by the decided design. In this market, flow is money. The

more flow per valve opening, the better. The valve must also produce efficient

flow avoiding adding to much heat to the gas due to friction. With a few types

of operations decided on, a decision matrix will be implemented to assure that

the design decided on is indeed the best design overall. The proposed

rotational valve will be included in the matrix to decide of it is one of the

better choices.

After the mode of operation is known and the desired flow rate is

achieved, materials for the fabrication must be chosen. The materials for the

entire valve must be able to withstand long time exposure to natural gas.

Further more, the valve must be airtight. No amount of gas can seep around or

through the valve. So a type of seal must be implemented in which can also last

the life of valve itself.

With the style of valve, the desired flow rate achieved, and

necessary materials are chosen, a pro-type must be produced. To do this, we

will use a 3-D modeling program such as ProE to produce a digital model of the

valve. With the digital model complete, we can then produce the physical part

itself. Most of the parts will be sent to the on campus machine shop to be

fabricated. Any part that is too intricate to be fabricated on campus will be

sent to GE to be made. Any parts such as springs and bolts will be purchased

for a local store of off the Internet.

Having the part produced then allows us to build a working

simulation. Along with group 19, whom are producing the digital instruments and

software to be able to analyze the system, a physical representation of the gas

compressor will be made. Both the sensors and valve will be modeled.

Product Specification

It is important that

the valve has a balance of cost, reliability, and performance. If the product

turns out to be more expensive than the existing valves, the pros must out

weigh the cons. The desired mode of operation of this valve is a rotational

manner. When the desired pressure of the gas cylinder is achieved, the valve

must rotate to allow the gas to flow out. When the pressure drops, the exhaust

valve must rotate shut as the intake valve rotates open. Then again, as the

pressure increases, the intake valve must rotate shut. This device should be

able to be used as both an intake and exhaust valve. The device should also be

able to be fitted onto all or most of the gas compressor out on the field today. This product should be able to be easily installed in

replace of the existing plate and poppets valves with no modification to the

compressor. The entire project should fall within the budget range of two thousand

dollars.

Costumer Needs

• Product must operate in a rotational manner

• Flow volume and efficiencies must out perform

current designs

• The valve’s cost must be justified by its

performance including efficiency, cost, and

lifetime

• The product must stay in the budget range of

$2000

• A working model is to be made at the end of

the design process

Expected Results

The valve should operate at a higher efficiency than the current

model and have a higher factor of safety. A rotating action will open the valve

as well as close it with a tight seal. This rotation may be actuated by an

electric motor or a mechanical system synchronized with the compressor. Our

design must be contain the complexities necessary for operation but still be

simple enough to ensure durability and ease of installation.

Constraints

A G.E high speed reciprocating gas compressor has specific

pressures and temperatures that it operates between. Exact dimensions of the

space where the valve fits will constrain the size and shape of the design. The

valve must be tested thoroughly to ensure that the design concept and material

selected can withstand the rigors of operation. The valve must be designed,

fabricated, and tested within the allotted time frame of 18 weeks and the

budget determined by G.E

Project

Plan

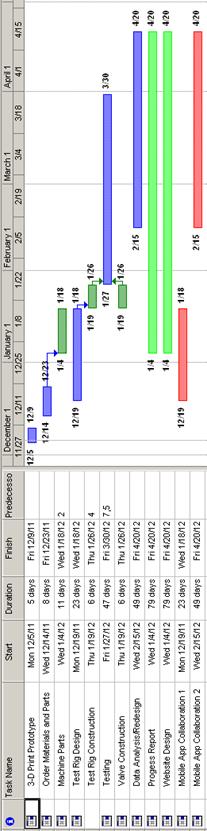

To begin the

semester, the ordering of all the materials is to be completed. Once the

materials have been ordered, the design of the valve will be “touched up” and

finalized so the drawings and materials can be sent out for machining. As the

parts are being machined, a test rig will be designed and constructed. The rig

will be fitted with thermocouples, pitot-static tubes and pressure gauges to

collect data. Once the parts are machined, the construction of the valve will

take place. With both the rig and valve constructed, extensive testing will be

done. If time allows, the test results will be used to improve the original

design and create an improved final design prototype. Our group will be collaborating with group

19, Mobile Application for Android, to be able to compare results and join

designs. During the entire process, the website will be updated on a weekly

basis.