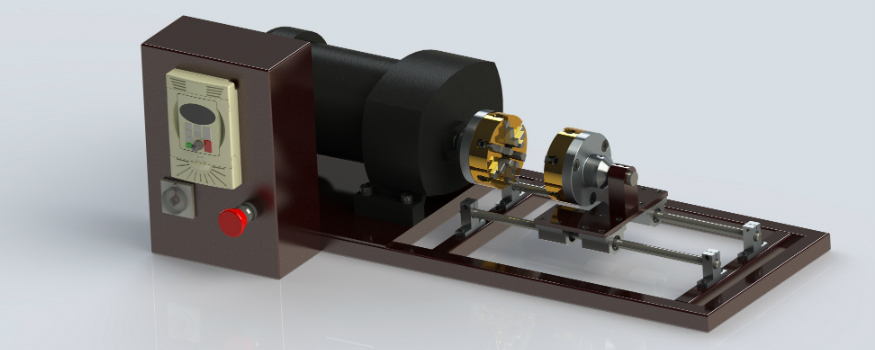

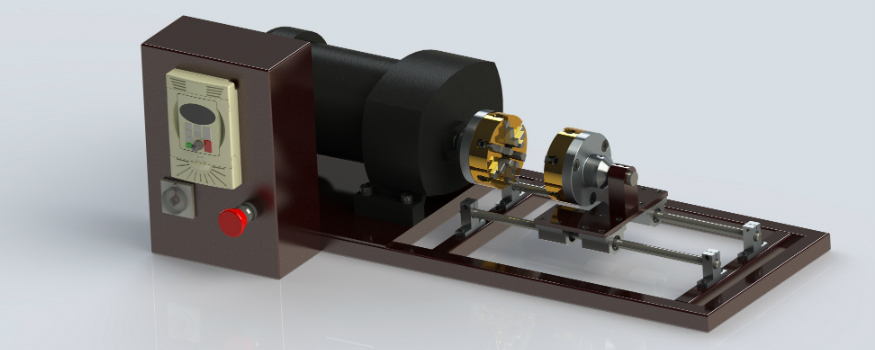

Tabletop Torsion Device

-

Our Sponsor

The Munitions Directorate at Eglin Air Force Base has a need for a torsion testing machine that will be used for small scale specimens.

The testing machines that the Munitions Directorate have been using in the past are intended to be used for large specimens,

and when used on small samples they are not accurate enough. This is a result of a low signal to noise ratio that accompany these large testing machines,

so therefore the Munitions Directorate has requested a smaller torsion testing machine for the small samples.

VISIT LIVE

-

-

Project Scope

Materials are the building blocks of our physical world.

From a designer’s standpoint, knowing the limitations of the materials is of the utmost importance.

There is always the trial and error route of constructing a mechanism or specimen and putting it to use until it fails, but this would prove to be extremely costly.

A better route would be to develop a method to test these materials by allowing it to endure the same loads it will when it is put to purpose.

The Eglin Air Force Base’s Munitions Directorate has done extensive research in the field of testing mechanical properties of materials commonly used in projectiles.

They are interested in how different materials react under different loads to simulate different scenarios of diverse mediums that the munitions will be fired at.

This being said, the group is constrained to the size of the specimens that they can generate. The reason for limited plate thickness is not a matter of cost, however.

it is a matter of geometry. When the Munitions Directorate is fabricating components of the munitions they use raw stock that is as close to final shape as possible.

to conserve waste material. In order to properly characterize the materials that end up in a product they have to simply test similar geometry in order the get accurate results.

Our group was tasked with developing and testing a smaller torsion device that will be more accurate than the machine they are currently operating.

-

Our Sponsor

The Munitions Directorate at Eglin Air Force Base has a need for a torsion testing machine that will be used for small scale specimens. The testing machines that the Munitions Directorate have been using in the past are intended to be used for large specimens, and when used on small samples they are not accurate enough. This is a result of a low signal to noise ratio that accompany these large testing machines, so therefore the Munitions Directorate has requested a smaller torsion testing machine for the small samples.

VISIT LIVE -

Project Scope

Materials are the building blocks of our physical world. From a designer’s standpoint, knowing the limitations of the materials is of the utmost importance. There is always the trial and error route of constructing a mechanism or specimen and putting it to use until it fails, but this would prove to be extremely costly. A better route would be to develop a method to test these materials by allowing it to endure the same loads it will when it is put to purpose. The Eglin Air Force Base’s Munitions Directorate has done extensive research in the field of testing mechanical properties of materials commonly used in projectiles. They are interested in how different materials react under different loads to simulate different scenarios of diverse mediums that the munitions will be fired at. This being said, the group is constrained to the size of the specimens that they can generate. The reason for limited plate thickness is not a matter of cost, however. it is a matter of geometry. When the Munitions Directorate is fabricating components of the munitions they use raw stock that is as close to final shape as possible. to conserve waste material. In order to properly characterize the materials that end up in a product they have to simply test similar geometry in order the get accurate results. Our group was tasked with developing and testing a smaller torsion device that will be more accurate than the machine they are currently operating.