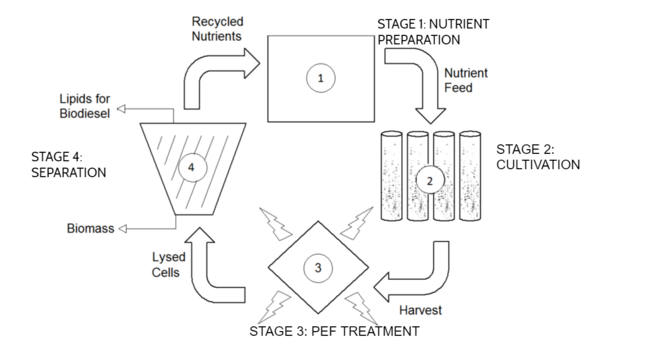

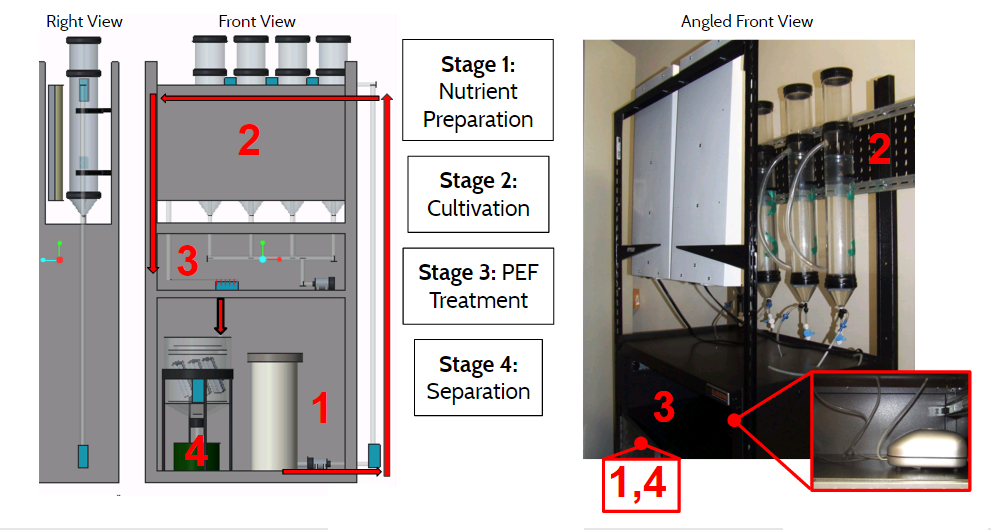

As a result of waning fossil fuel resources it is desirable to have access to a sustainable alternative energy source. Microalgae photo bioreactors are viable options for simple and sustainable energy source production. The operation of these bioreactors has the potential for automation and produces environmentally friendly biomass and biogas which have many widespread applications, as aforementioned. The current state of microalgae photo bioreactors is very dependent on consistent maintenance and check-ups to keep the algae growing. In addition, there are no viable methods for automated harvesting of the microalgae. This is unsatisfactory because it limits the scope of utilizing microalgae as a large scale biofuel source. UFPR in conjunction with FSU are sponsoring the Senior Design team to develop a continuous harvesting system which requires minimal intervention as a solution to the harvesting problem.

Lysing Process Begins

Litre of Algae Arrives

Walk through Presentation at College of Engineering

Team 9 wins 2nd place in Alabama Competition

Spring Break Begins

Electrodes Constructed

Construction for Automation Begins

Algae Cell Count Begins

Construction for airlift began

Update Presentation

Algae ordered

Team reunited at FSU

Website updated

Group Meeting

Automated system components ordered

Midterm Presentation 2

Group Meeting

Pulsed electrical field flocculator components considered

Group Meeting

Group Meeting

FSU algae cultivation complications-excessive evaporation.

Group Meeting

FSU algae cultivation initiated

FSU algae cultivation infastructure implemented

Midterm Presentation I

Conceptual Design Completed

Group Meeting

Sponsor Meeting with Dr. Ordonez- discussed budget and lab set up

Group Meeting

Project Plans and Specifications Report Submitted

First website launch