Plain Carbon Fiber

Toray T300 carbon fiber and Epon 862 epoxy resin. This is the stongest system compared with the other two.

Carbon Fiber Hybrid

This system combines the best of the virgin and recycled composites. This will provide the preferred properties at the lowest cost.

Recycled Carbon Fiber

This system is 60% less expensive that the virgin carbon fiber. However, this comes at the cost of significantly less strength.

Abstract

The

goal of this project is to introduce a composite material that

can replace aluminum airframe beams in military aircraft. The

project sponsor, Northrop Grumman, is exploring ways to reduce

the cost of incorporating composites. Carbon fiber reinforced

polymer is extremely strong and lightweight, but it is

currently very expensive. The team used recycled material to

mitigate the high cost of carbon fiber. The team designed

three carbon fiber beams with the same strength as a currently

used aluminum beam. The first beam uses T300 plain weave

carbon fiber; it is the lightest and most expensive. The

second beam uses recycled carbon fiber; it is the heaviest and

cheapest. The third beam is a mixture of T300 and recycled;

the optimal proportions were found by comparing the cost and

weight of the T300 and recycled beams. Each beam uses epoxy

resin because it is the cheapest material that meets the

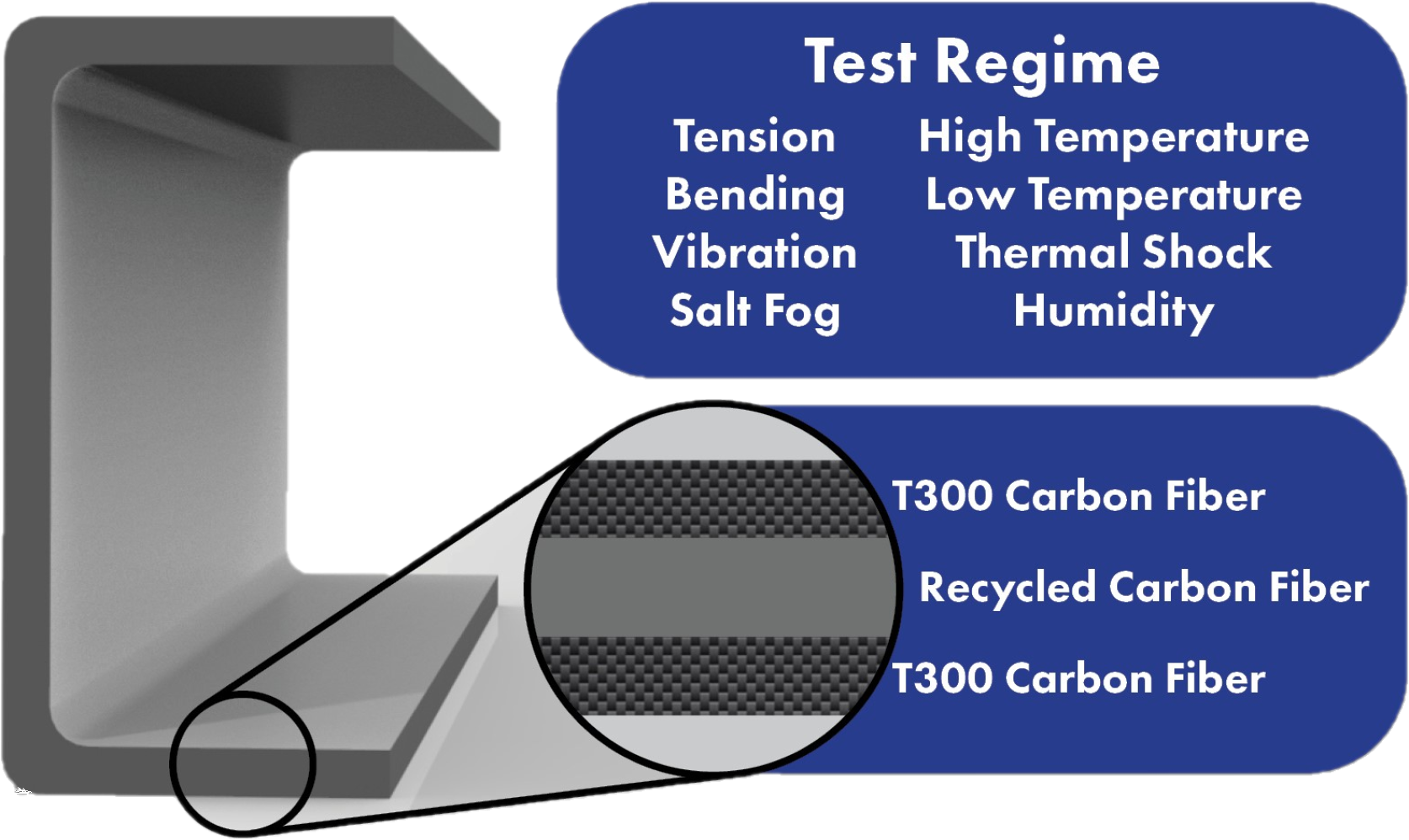

strength requirements. The beams must provide strength in all

operational conditions, such as high temperature, low

temperature, vibration, thermal shock, humidity, and salt

atmosphere. The team designed and performed a series of tests

to validate that the beams are suitable for use in these

conditions. The outcome of this project is a method to select,

test, and validate composites for use as an airframe

component.

test regimen

Click Results To View Data

|

|

Recycled | T300 | Hybrid |

| Flexural Strength |

Results |

Results |

Results |

| Tensile Strength |

|||

| High Temperature |

Results |

Results |

|

| Low Temperature |

Results |

Results |

|

| Humidity |

Results |

Results |

Results |

| Salt Atmosphere |

Results |

Results |

|

| Thermal Shock |

Results |

Results |

|

| Vibration |

Results |

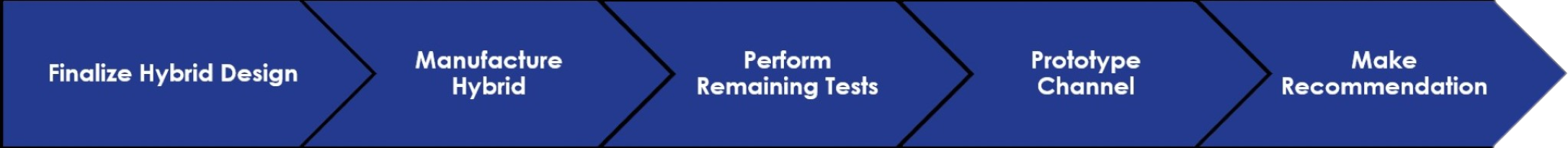

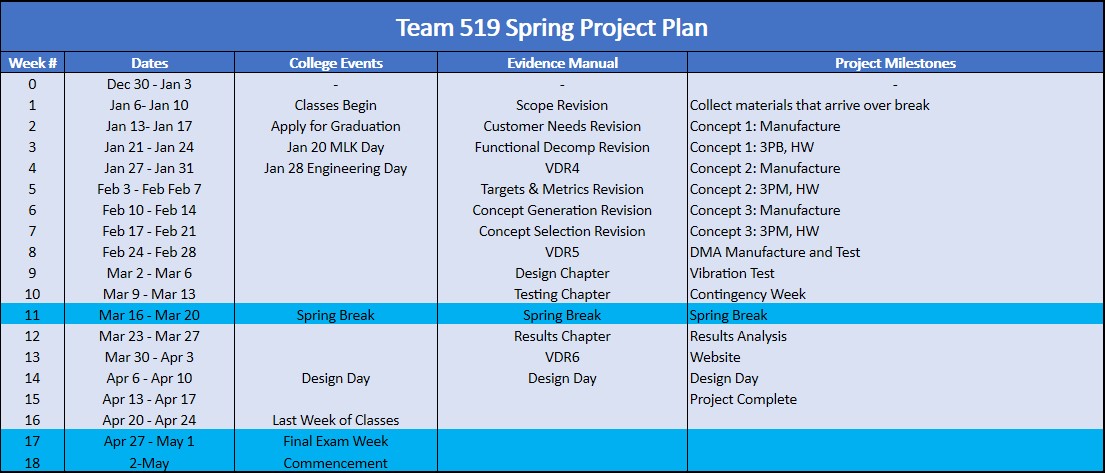

FUTURE WORK

Below Is a Timeline of Upcoming Work

Team

Meet Senior Design Team 519

Stefan Spiric

Test EngineerStefan is a mechanical engineering student who is interested in aeronautics. Stefan enjoys working on projects for student organizations like Society of Automotive Engineers. Stefan plans on pursuing a career in the defense industry.

Gabrielle Mohrfeld

Manufacturing EngineerGabrielle is a mechanical engineering student with an interest in aeronautics. Gabrielle balances her time studying and participating in student organizations as she is the president of the American Society of Mechanical Engineers.

Cecil Evers

Materials EngineerCecil is a mechanical engineering student who plans on pursuing a masters degree once he graduates. Cecil is interested in material science and currently does research at the High Performance Materials Institute .

Christopher Ryan

Design EngineerChristopher is a mechanical engineering student with an interest in material science. Christopher hopes to enter the defense industry after graduation. He is currently an intern at a local engineering firm.