DANFOSS AFTERMARKET WORKFLOW

PROCESS CREATION AND IMPLEMENTATION

Sponsored by: Danfoss Turbocor

Team 504

FAMU-FSU COLLEGE OF ENGINERING

ME DEPARTMENT

Abstract

Danfoss Turbocor wishes to improve the process of replacing parts for damaged compressors returning from the field. The current job of a planner is to find the appropriate replacement parts. Our goal is to help the planner by streamlining and automating this process. We are implementing a MATLAB script that produces a bill of materials of suitable replacement parts for a damaged compressor.

There are three reasons that parts need replacement: failure, compatibility, and obsolescence. Planners filter through these factors to determine the proper replacement parts. There is no standard procedure for this process which has led to organizational problems within Danfoss production. Therefore, we are creating a system that determines part replacements based on the criterion for replacement. Our system identifies the most recent revision of a failed part. If a replacement depends on other parts, the other parts must be added to the bill of materials as well. Furthermore, our system determines whether a part is obsolete. This prevents outdated parts from entering the bill of materials.

Our team is designing a MATLAB script to organize the part replacement process. The script automates the logic for part replacement. Certain scenarios are dependent on the intuition of the planner. We discussed this issue with Danfoss personnel and developed a way of addressing these problems. Therefore, the script is used with a standard which handles the manual side of planning. Together, the script and standard produce a final bill of materials. While we have designed our system to handle Danfoss’s TT/TG model compressors, our system is formatted to be replicated for all Danfoss compressor models.

Master Scheduler

BOM Lookup Tab

The BOM Lookup Tab has two primary functions. First, it determines what static BOM should be used for the given compressor number. For these two input fields are provided: part # and MO (Manufacturing Order). The part number or compressor unit number is used in determining which static BOM should be used for planning aftermarket production. The MO simply follows the compressor down the line and is attached to the final BOM. Once the part number is entered by the user, the app determines the group, group \#, and Static BOM that should be used for this compressor repair. These three fields are then displayed for the user in edit fields. The secondary functionality of the BOM Lookup Tab is the upload feature. Now that the static BOM is known, the upload feature is used to upload the appropriate static BOM to the app. This static BOM will be used in future features within the app.

Decision Matrix Tab

The Decision matrix panel is comprised of a panel you can input the component number of the four major parts: IGBT, CAP, PWM, SCR. In addition to the input fields, there are good and bad check boxes that determine the structural integrity of the part. To the right of the input panel there is an action text box that lets the user now what the app is doing with those four main components. Finally, there is an OK button that activates all the functionality. Based on the weather the 4 main components are on the static BOM, and the structural integrity, the part enters 4 possible cases.

Repair List Tab

The Repair List has two main functionalities: a manual repair list and upload file feature. The manual repair list allows the user to input component numbers and their associated quantities. From the component numbers entered, the component number's description is generated using the BOM Lookup.xlsx file. For each component number added the application will determine if the component number exists within this file, and if it exists it will be added to the repair list. Each entry contains four components row number, component number, description, and quantity. If two of the same component numbers are entered, then the row will be highlighted red and an error dialog box will be displayed to the user saying "Please delete repeated component." There is also a deletion feature which allows the user to delete rows they do not want to be contained within the repair list. The second functionality is an upload feature. This feature can serve to replace or supplement the manual repair list. Its functionality is the same as that of the first upload feature, see the BOM Lookup tab for more details.

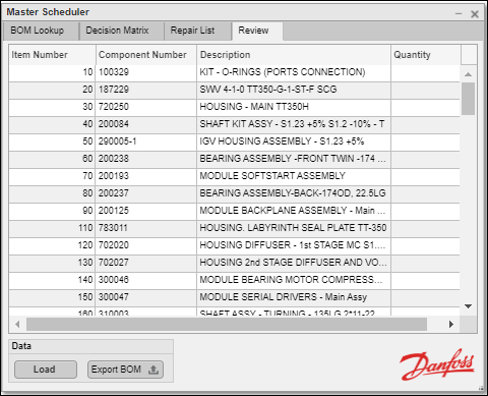

Review Tab

The Review Tab is a sum of the revised static BOM and the repair list. This information is displayed in a UITable. The table is updated by passing the final results from each tab as global variables to the final tab. The two tables, the revised static BOM and the repair list, are concatenated into one final table. Then some functions were made within the app to get rid of duplicate items on the final BOM. In addition, there is a sheet on the BOM Lookup file called Comments that contains an obsolescence list. The app cross-references the component numbers on the final BOM with the components on the obsolescence file. Within the obsolescence file is the correct replacement for each associated part. The app deletes the obsolete part off of the final BOM and adds the correct replacement on the end of the final BOM. After these changes are applied, the final BOM can be exported to an excel file.

Our Team

David Bishop

Systems Engineer

Julian Villamil

Systems Engineer

Alex Wilson

Design Engineer

Kyle Youmans

Design Enginner

Deliverables

Fall 2020

Project ScopeCustomer Needs

Functional Decomposition

Targets and Metrics

Concept Generation

Concept Selection

Bill of Materials

VDR1

VDR2

VDR3 (Poster)

Spring 2021

DR4DR5

DR6

Final Poster

Operation Manual

Spring Item Tracking (Current)

Evidence Manual