The Project

The objective of the project is to articulate a nose cone during testing in a subsonic wind tunnel.

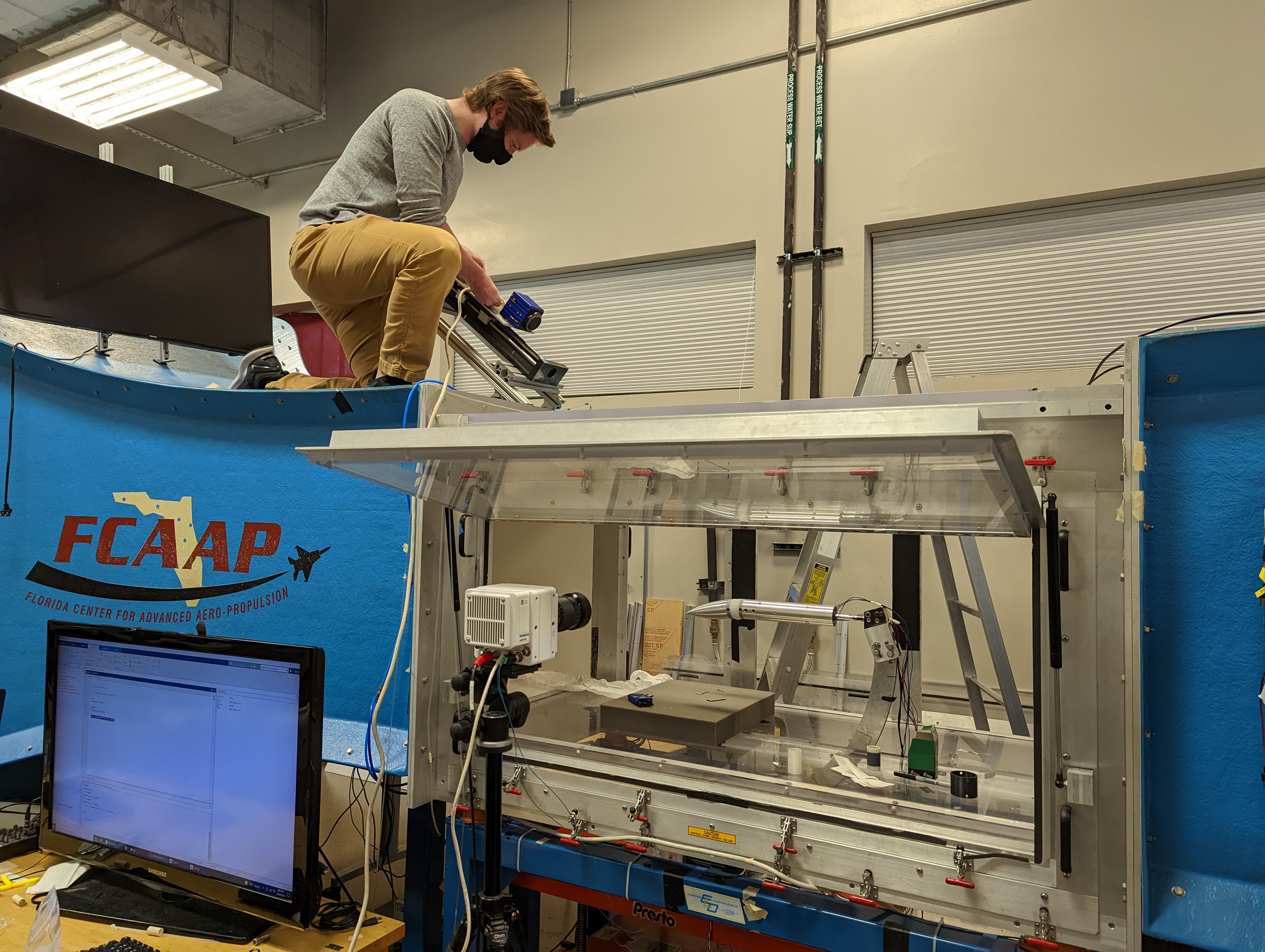

The team was tasked with implementing a new flight control method for the Florida Center for Advanced Aero-Propulsion (FCAAP). Current missile technologies frequently use fins to control the missile. Control through the use of fins requires them to be rotated against potentially high forces, which requires powerful and sizable motors to operate which uses crucial space. With the removal of the fins, more space would be made available within the missile, allowing for increased available storage items such as fuel. Due to the potential benefits of finless missiles, FCAAP is looking into new methods to gain control without the use of fins.

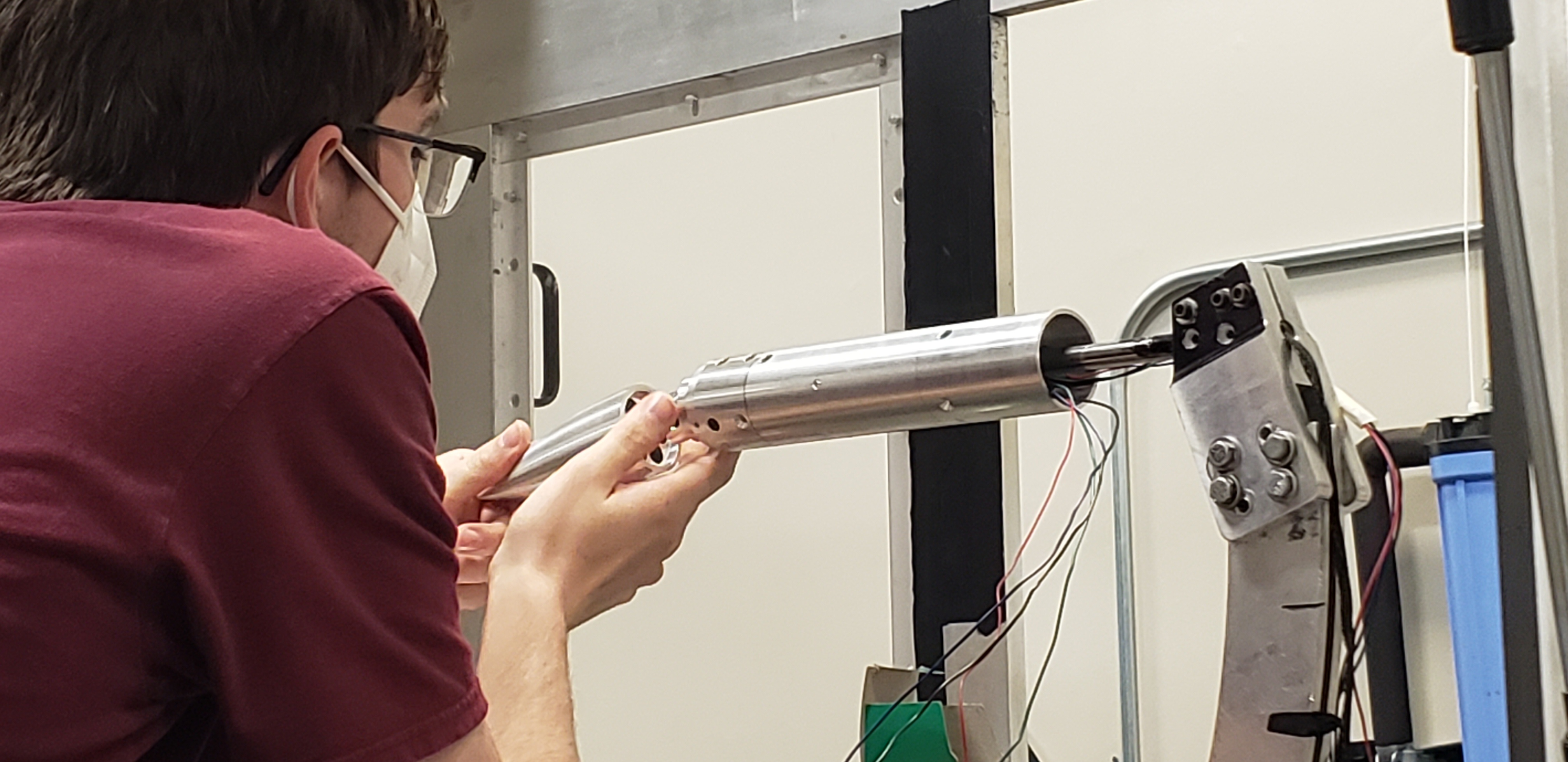

One area that shows great potential for control is the nose cone. As the nose cone is a critical component allowing for flight, it is necessary to have on most all high speed flying vehicles. Thus, making modifications to the nose the optimal choice for enhancing the missile control. Our goal is to create a rotating nose cone model that allows for control without the use of fins.

The model will be tested in a low-speed wind tunnel to test the validity of the rotating nose concept. To control the rotation and angle of the nose, internal motors are connected to a controller located outside the tunnel. When hooked up to the computer, the nose is user-controlled through software. Using analysis software and coding, the impact of the rotating nose on the control of the missile will be analyzed through the process of particle image velocimetry (PIV). PIV involves obtaining a pair of images and comparing them to visualize how the air moves around the missile. Using these results the team will determine how well the articulated nose performs at controlling the flow around it and if it is a suitable alternative to fins.

The critical goals for our project were as follows:

- Articulate the nose cone up to 20 degrees.

- Mitigate the edge effects caused by the nose cone rotation.

The Team

Jed Fazler

Materials Engineer

Jed Fazler is a senior in mechanical engineering looking to pursue a career in the aerospace industry. Jed assisted with this project as the materials engineer.

Noah Moffeit

Design Engineer

Noah Moffeit is a senior in mechanical engineering looking to pursue a PHD in aerodynamics. Noah's focus on this porject was developing the CAD and operating methods of this project.

Nicholas Samuda

Systems Engineer

Nicholas Samuda is a senior in mechanical engineering looking to pursue a career in control systems. Nicholas assisted as the systems engineer.

Robert Smith

Research Engineer

Robert Smith is a senior in Mechanical engineering who is plannign to progress torwards a PHD in Mechanical Engineering. Robert helped contribute to the coding and control for the model.

Sponsor and Advisor

Deliverables

The following deliverables provide an overview of the crticial parts of our project. The evidence manual is a catalog containing numerous items such as the project scope, customer needs, functional decomposition, targets catalog and summary, concept generation, and our second semester project plan.

Evidence Manual

Bill of Materials

Risk Assessment

Operation Manual

Design Review 1

Design Review 2

Design Review 3

Design Review 4

Design Review 5

Design Review 6

Photos