Team 520

Desktop CNC

Creating a custom rapid prototyping system for designers and engineers

Firebird Concept

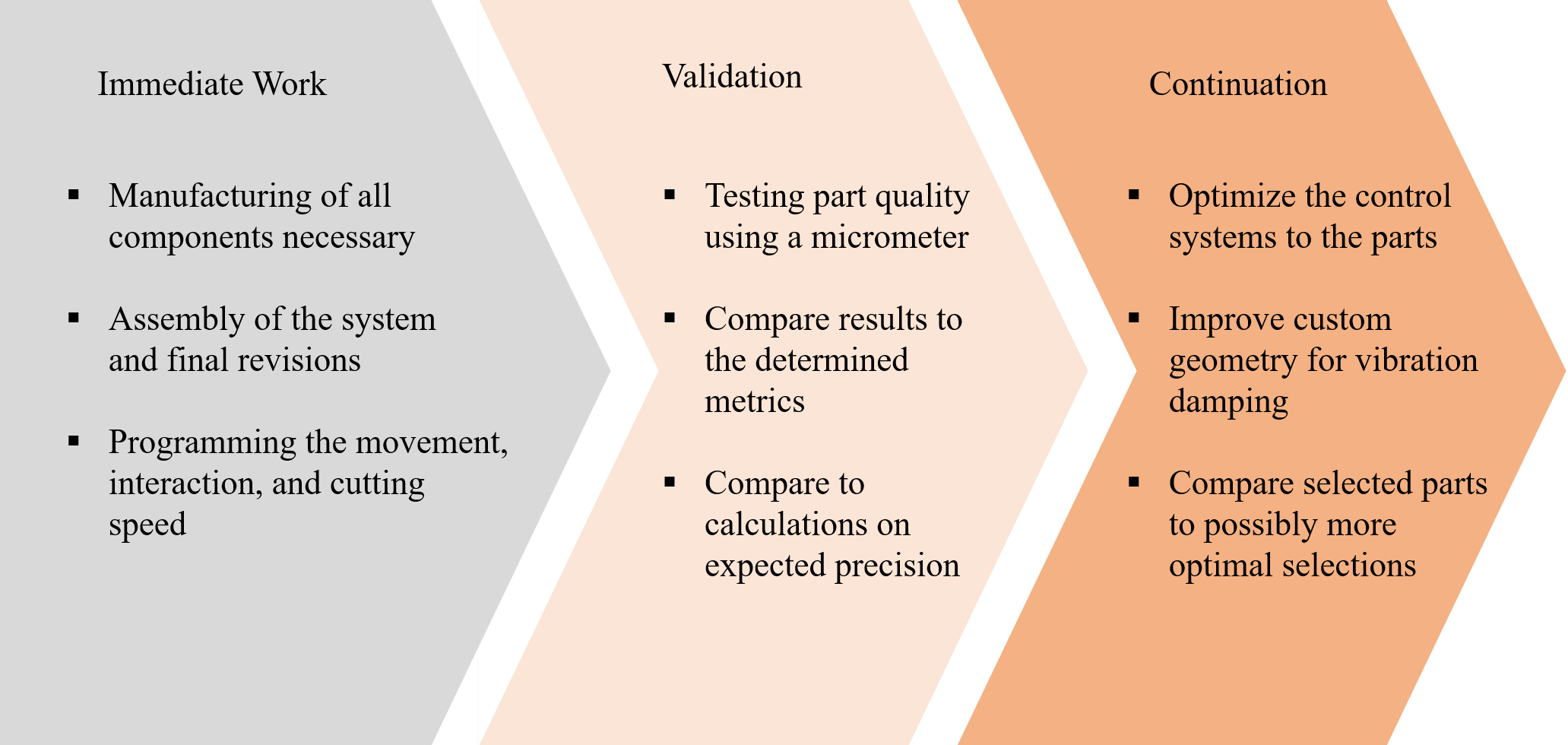

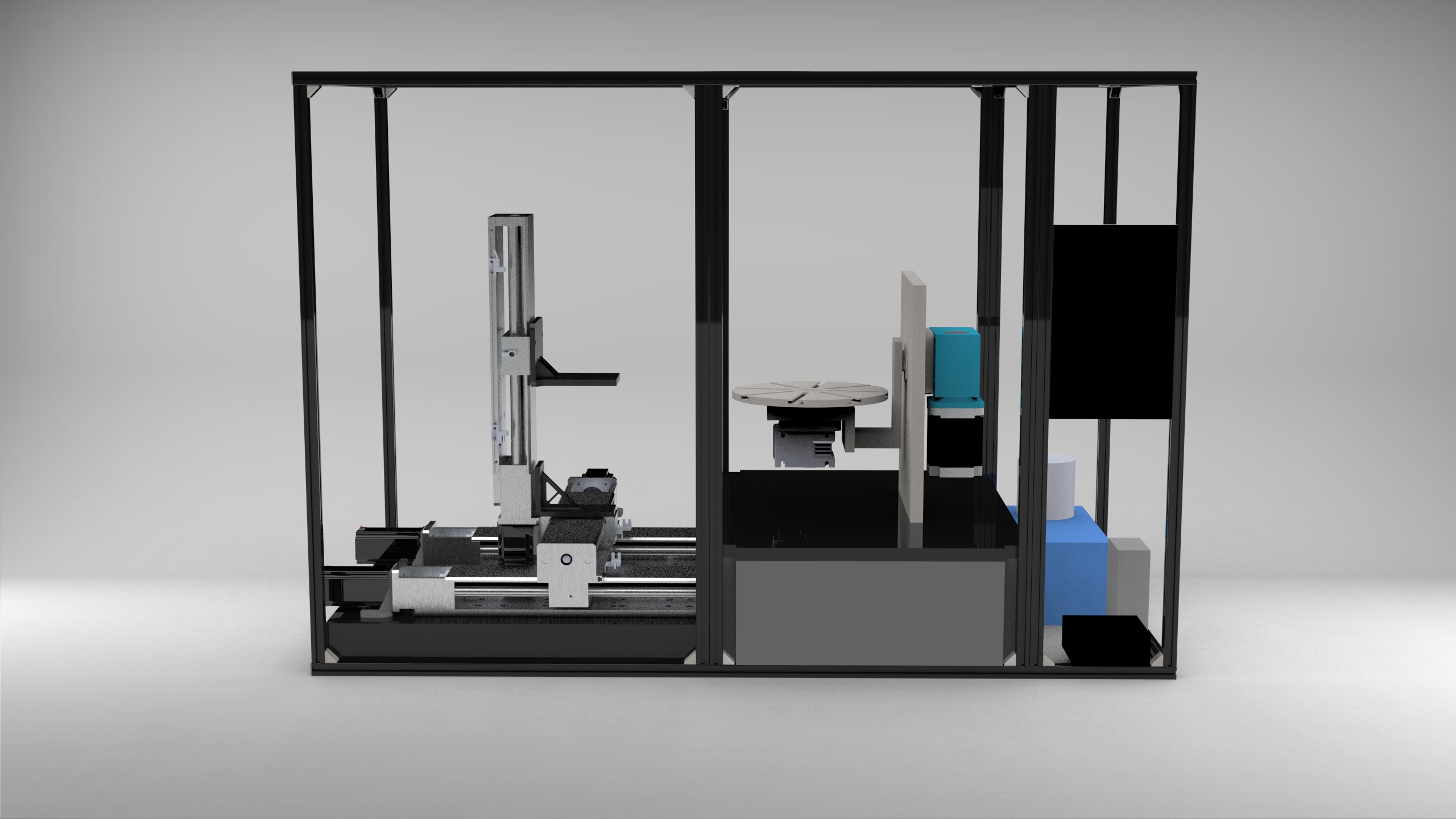

For this project we are developing Firebird, a desktop-sized five-axis CNC milling machine. This is a machine that fill the void currently between the 3D printer and the CNC milling machine markets. 3D printers currently control the market due to their ability to fit on a desk, ease of use, and that they are cheap enough for the average person. However, 3D printers make low quality parts, are slow, and only work with plastic. CNC milling machines are extremely fast, very precise, and can work with a range of materials. However, they are expensive, hard to operate, and require a large space to store. Firebird will take the best of both markets, which includes the ease of use, size, and price of a high-end 3D printer. While also taking the versatility, capability, and precision from a five-axis CNC mill. By using the most advanced technology available, Firebird will have more options, have faster production times, and make higher quality parts than current machines. The most important components will be the structure, linear guides, and operating system. The frame must be able to control and reduce all forces and vibrations on the machine. The linear guides must move around accurately and quickly with minimal error. Finally, the operating system must control the machine, be easy to use, and efficient. Combining these leads to a machine that is much more convenient and capable than anything available currently. The goal of the project is to have a complete machine that will be on the market by March, cost under $8,000 to build, and sold around $15,000. At this price point and with the technology in it, there is nothing available on the market that can compete which makes it more desirable.