Dow Inc. is a company known for producing polyurethane, rubber, and acrylic acids.

Producing these materials creates toxic gases that can cause explosions and chemical fires. To

uphold safety standards, Dow sends employees to inspect and repair pipes used for production.

This task has put workers at risk of toxic gas exposure. This exposure can lead to fainting or

death. Team 514 aims to reduce the risk of harm to the worker as they perform inspections and

repairs.

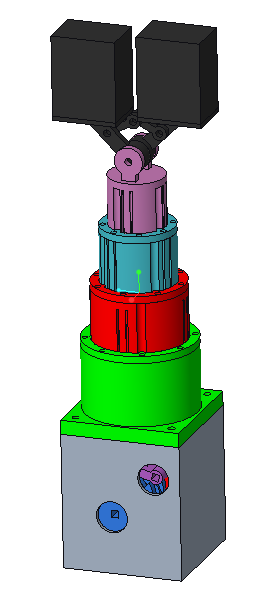

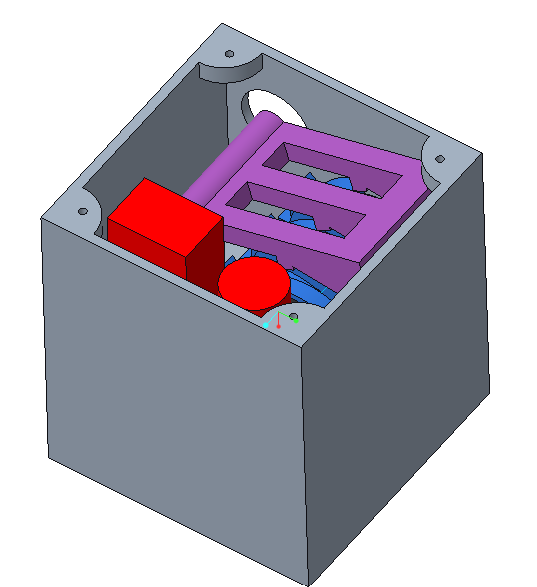

To help workers safely perform these tasks, Team 514 designed a robot named Luffy.

This robot removes the need to send someone to find out if the environment is safe for workers to

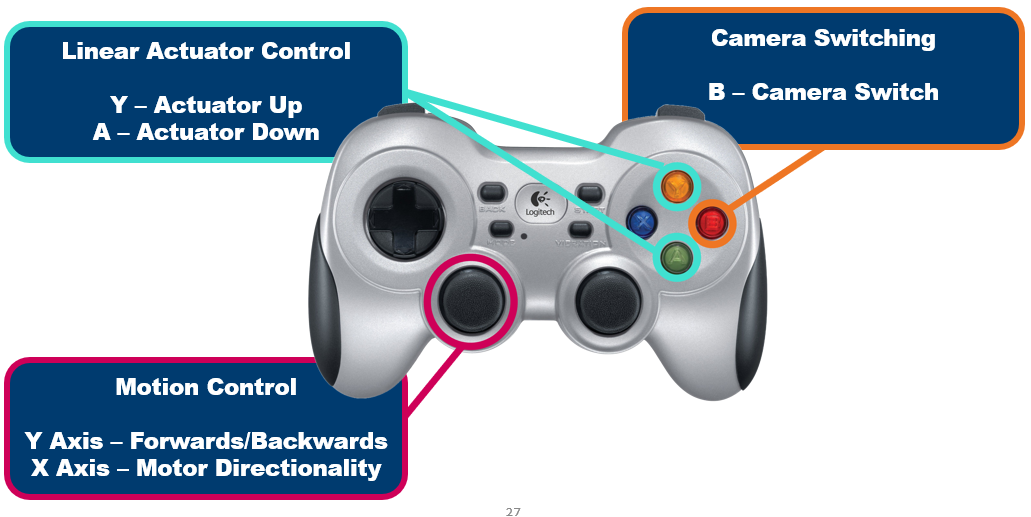

enter. The worker will have a controller that controls Luffy’s tank tracks and a telescoping arm.

The arm helps Luffy climb up or down a pipe by constantly pressing against the pipe wall. The

robot body holds three gas sensors and two wide-angle cameras. These parts should allow the

user to inspect cracks and gas levels inside a pipe without exposing the worker to a toxic

environment.

The following constraints motivated the design of Luffy: it must fit within different pipe

sizes, move using a remote control, and use gas sensors to detect gas leaks. These limited the list

of solutions that satisfied the project objective. This gave the team more time to evaluate and

verify the final design. Luffy successfully moved through pipes and climbed areas with 45- to 90-

degree inclines. The cameras mounted on Luffy successfully livestreamed video to a computer

screen with minor delay. Also, the gas sensors reported accurate air quality levels to the user

through Wi-Fi. Team 514 created a successful design that can help identify basic inspection

targets like gas leaks and pipe cracks.

Meet the mentors that make this project possible.

Meet the mechanical engineers in charge of completing this project at the FAMU-FSU College of Engineering.

Design & Manufacturing Engineer

Florida Agricultural and Mechanical University

Photos of the progress we have made.

All of our hard work for you to see:

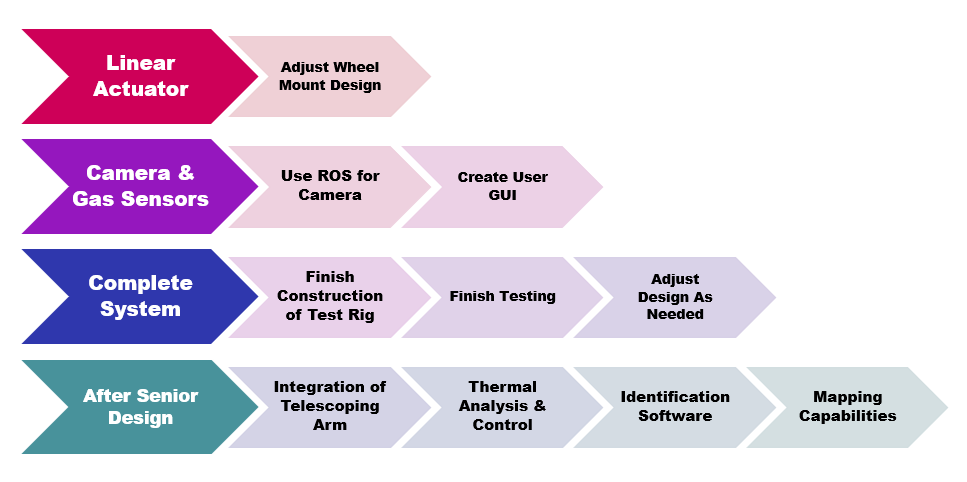

An overview of the work remaining for this project.