As mentioned before the rotary engine is an Otto Cycle engine. It has four stages that convert an air fuel mixture into mechanical power. What is different about the Rotary engine is the way these cycles occur and the location where they happen.

In a regular piston engine the cylinder is the place where intake, compression, combustion and exhaust occur. This means that the piston cylinder is doing four different jobs at different times. For a rotary engine each part of the housing is designed specifically for each one of the major cycles.

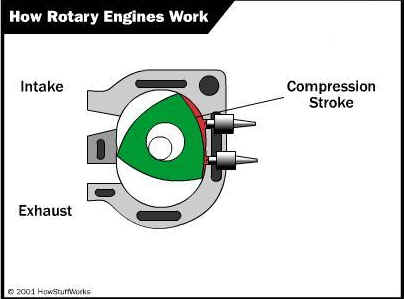

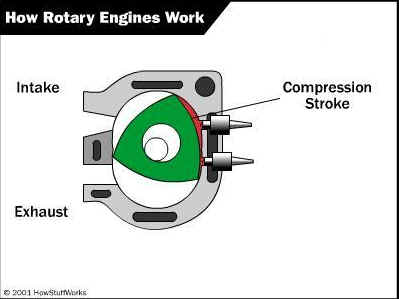

Intake is obtained in a rotary engine by volume expansion. The rotor passes by the intake ports and creates a chamber that expands its volume allowing more air to enter the engine. When the tip of the rotor passes the intake port the chamber is at its minimum volume. As volume expands the air fuel mixture is drawn into the chamber. Once the maximum volume of air is obtained the intake stroke ends with the closing of the chamber.

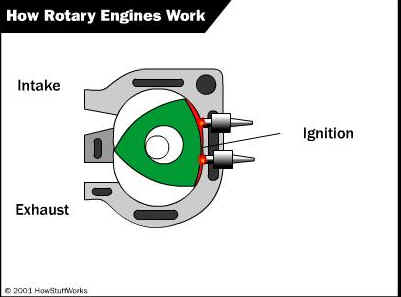

At this point compression begins. The chamber where the air fuel mixture is trapped begins to reduce its volume compressing the mixture of air and fuel. At the point the rotor tip reaches the second spark plug the volume of the chamber has been reduced to its minimum and ignition begins.

A very long chamber is obtained for ignition. The use of two spark plugs is common in rotary engines, this allows for better fuel burning in the chamber. Ignition begins when both spark plugs are fired at the same time.

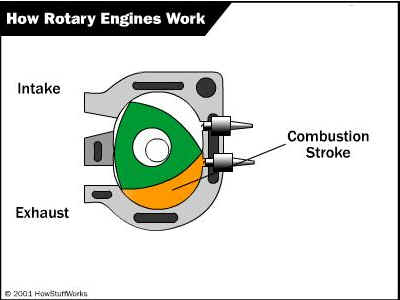

At this point the rotor is forced to rotate expanding the combustion chamber to the maximum. Combustion allows the rotor to move the output shaft creating mechanical output from the engine. The motor creates power until the tip of the rotor reaches the exhaust port.

Once the rotor reaches the exhaust ports the exhaust stroke begins. This is obtained with the reduction of volume of the chamber allowing all hot gasses to exit the chamber in a very short time. By the time the back tip of the rotor passes the exhaust port the whole cycle starts again with the intake stroke.

It is important to note that at any given time the rotary engine has three different strokes going on a the same time while a regular piston engine is only allowed to do one at the time. For every revolution the rotor does there are three different combustion strokes in it. The output shaft rotates three time fore every revolution the rotor does. This means that for every combustion stroke of the rotor there is one revolution of the output shaft.