There are many key differences between a convencional piston engine and a rotary engine. Some of the most important ones is the number of pieces that the rotary engine has compared with the number found in piston engines. A four cilynder piston engine has roughly 40 moving parts while a double rotor engine has 4. Rotary engines do not have valves, cams. camshafts, valve springs, timing belts and connecting rods.

Rotary engines have higher reliability rates because they have fewer moving parts. A rotary engine is smoother in any application because all parts are rotating in the same direction while a cylinder engine has linear motion of the pistons being translated into rotating motion on the output shaft.

Parts move slower in a rotary engine because for every revolution the rotor does the output shaft is forced to rotate 3 times.

Triple rotor engine under development.

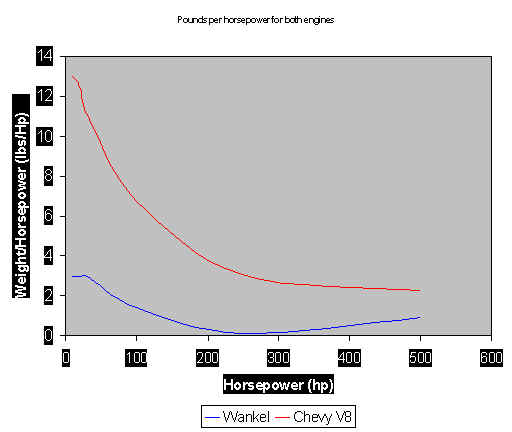

Fewer moving parts mean that a rotary engine will weigh substancially less than a cylinder engine with the same ammount of power.

The figure above shows a curve of weight over horsepower Vs horsepower for a rotary engine and a chevy V8 of comparable power. It takes substancially less weight per horsepower for a wankel engine to obtain the same ammount of power that the chevy engine. At 500 horsepower and above one can see the weight over horsepower curve increases for rotary engines but the chevy curve is already flatening out keeping rotary engines above the V8 counterpart.

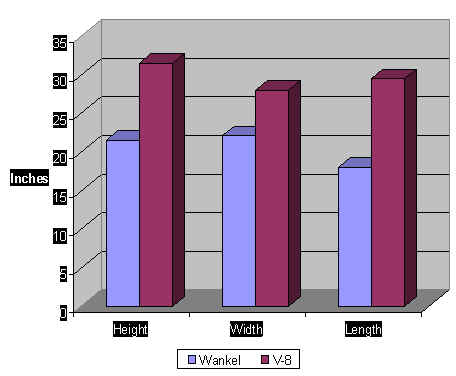

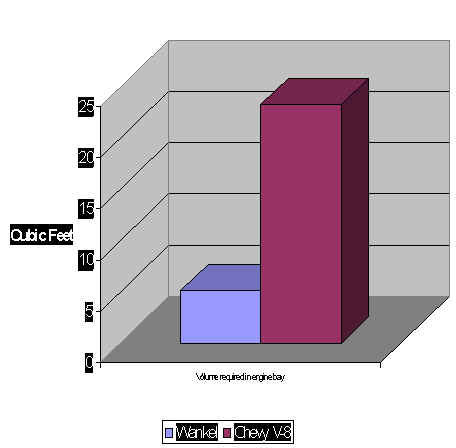

The following two pictures show the difference of weight and volume between the two engines compared above.

Figure above shows difference of size of comparable power engines.

The figure above shows volume required for engine with all accesories mounted.

Rotary engines have had a harder time meeting us emmissions making them not so popular being the california marked the biggest automobile market in the world.

In theory a rotary engine should be cheaper to build because of fewer parts. The low popularity of rotary engines makes costs higher. A car with a rotary engine costs much more money than a regular piston engine.

Rotary engines have low compression ratios because of sealing problems. Low compression makes the engine consume considerably more fuel than a regular 4 cylinder engine.

Some of these challegenes have been addressed on the new Renesys engine that will power the new mazda RX-8. Some of the solutions include a separate chamber containing the intake and exhaust ports to minimize overlap, higher compression ratio obtained by better seals, incorporates a 3 port intake and exhaust system that is actuated secuentially.

The new Mazda Renesys engine is rated at 250 Hp with a 1.3 litre displacement.