Helium Cryogenics for Accelerator Applications

Superconducting radio-frequency (SRF) cavities and superconducting magnets are essential components of modern and future particle accelerators. Their performance, reliability, and safety depend critically on the behavior of cryogenic helium systems, as many accelerator beamlines operate at liquid helium temperatures and increasingly below 2.2 K in superfluid helium (He II). Failures or inefficiencies in these cryogenic environments can lead to severe consequences, including cavity quenching, violent boiling of liquid helium, and dangerous pressure buildup in cryomodules. Motivated by these challenges and by priorities articulated in the Particle Physics Project Prioritization Panel (P5) report, our group has pursued a sustained research program on helium cryogenics for accelerator applications, combining controlled experiments, theoretical modeling, and practical diagnostics.

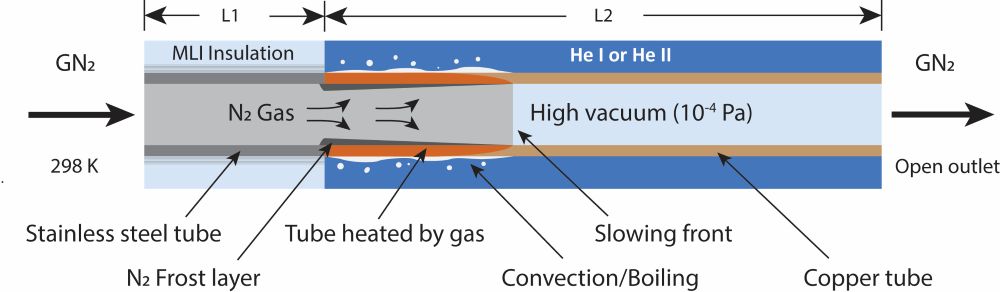

Sudden Vacuum Loss in Liquid-Helium-Cooled Beamlines: One major focus of our research addresses the dynamics of sudden vacuum loss in liquid-helium-cooled accelerator beamlines. In large SRF accelerators, cavities are housed in long, evacuated beamlines immersed in liquid helium. A catastrophic vacuum break allows room-temperature air to enter the beamline and rapidly condense on cold surfaces (see Fig. 1 for the schematic concept). The resulting heat deposition can drive violent boiling of liquid helium and rapid pressure rise, posing serious risks to both hardware and personnel. Understanding how condensing gases propagate, deposit heat, and interact with the surrounding helium bath is therefore essential for beamline safety design.

Figure 1: Schematic showing the propagation and deposition of nitrogen gas in a liquid helium cooled vacuum tube

Our group has conducted systematic experiments on gas propagation in evacuated tubes cooled by liquid helium, in both the normal-fluid (He I) and superfluid (He II) regimes. Using long copper tubes instrumented with distributed temperature sensors, we demonstrated that condensing nitrogen gas propagates far more slowly than non-condensing gases, with the gas-front velocity decreasing nearly exponentially along the tube. We developed a one-dimensional theoretical model that captures the coupled gas dynamics, radial condensation, and heat transfer to the liquid helium bath, successfully reproducing experimental temperature traces and enabling quantitative evaluation of heat deposition along the tube. More recently, we extended these studies to realistic beamline geometries incorporating bulky SRF-cavity-like structures. Experiments revealed highly anisotropic gas propagation, in which condensing gas can flush through a cavity volume before significant condensation occurs on cavity sidewalls. This behavior highlights the limitations of uniform-tube assumptions for real accelerator beamlines. Ongoing work focuses on systematic measurements in cavity-containing geometries and the development of fully three-dimensional numerical models to simulate gas propagation, condensation, and heat transfer. The results will inform safety-valve sizing, pressure-relief strategies, and beamline design codes.

Non-Contact Detection of Hot Spots in He II: A second thrust of our research focuses on diagnosing quench hot spots in SRF cavities cooled by He II. Although He II provides exceptional cooling capability, the maximum accelerating gradient of an SRF cavity is often limited by quenching triggered by sub-millimeter surface defects. Accurately locating these defects is essential for cavity processing and performance improvement.

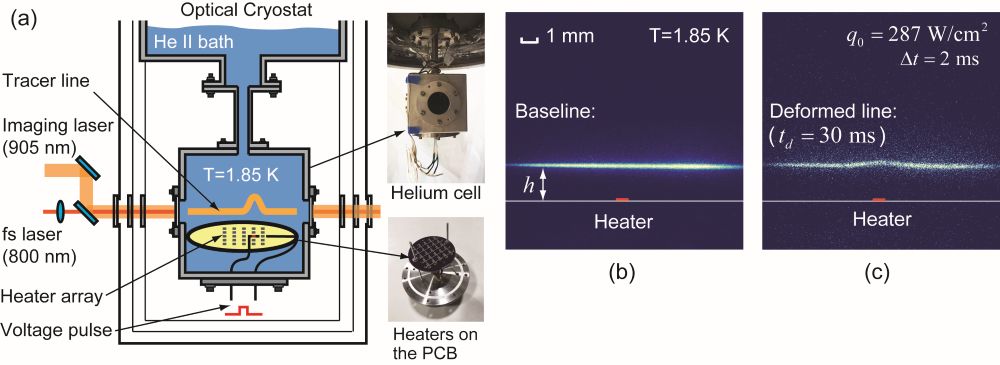

We pioneered a non-contact hot-spot detection approach based on flow visualization in He II. Using molecular tagging velocimetry (MTV) with metastable He2* tracers (Fig. 2), we demonstrated sub-millimeter localization of heater-simulated quench spots by imaging normal-fluid flow driven by localized heating. We further developed stereoscopic MTV techniques capable of reconstructing hot-spot locations in three dimensions. To enable broader adoption in accelerator laboratories, we are now developing particle tracking velocimetry (PTV) as a more practical alternative. PTV uses micron-sized tracer particles and simpler optical systems while retaining full-field velocity measurement capability. Our experiments show that tracer trajectories diverge radially from heated regions in He II, providing a robust signature for hot-spot localization. Ongoing work focuses on quantifying spatial resolution, extending the technique to three dimensions, and identifying tracer materials compatible with accelerator environments. We also conduct complementary numerical modeling based on the two-fluid equations of He II to study transient heat transfer from localized defects. These simulations clarify how heat is partitioned among boiling, quantized vortices, and second-sound emission, and provide quantitative criteria for reliable hot-spot detection.

Figure 2: (a) Schematic of the experimental setup used to demonstrate hot-spot detection in He II using the molecular tagging velocimetry (MTV) technique. (b) and (c) show representative fluorescence images of the He2* molecular tracer line at t = 0 and t = 30 ms, respectively, following a heat pulse generated at the hot spot.

Supercritical Helium Cooling for High-Temperature Superconducting Systems: A more recent direction of our research addresses cryogenic challenges associated with high-temperature superconducting (HTS) magnets for next-generation accelerators. HTS materials enable operation at higher temperatures and magnetic fields, but place stringent demands on coolant performance. Supercritical helium (SHe) is an attractive coolant because it avoids phase transitions while offering high thermal conductivity, large heat capacity, and improved thermal stability. Despite its importance, reliable experimental data on heat transfer in supercritical helium under accelerator-relevant conditions remain scarce, particularly near the pseudocritical region where thermophysical properties vary rapidly. To address this gap, we have initiated a dedicated experimental program to measure forced-convection heat-transfer coefficients of supercritical helium across a wide range of pressures, temperatures, and flow conditions. Using a purpose-built flow loop with precise control of operating parameters, we aim to generate benchmark heat-transfer data for validating and improving design correlations used in HTS magnet cooling. These results will directly support the development of stable and efficient cryogenic systems for future accelerator facilities.