Senior Design 2004/5: Group 10

Permanent Magnetic Return Torque Micro Bearing

John Anderson

Scott Kruse

Jacob Reese

Jared Smith

Cherrod Williams

| Home | Project Overview | Final Presentation | Assembly | The Group |

This design project was commissioned by Sandia National Laboratories. They needed a micro-bearing that would allow limited rotation and return to its original position once the rotational force is removed. Currently a bearing is in use by Sandia that uses springs for the return torque, but the assembly of this component into the system requires extra grounding for the spring. They suggested creating a bearing that uses magnetic material contained within the bearing to return the shaft to its original position. Sandia could not specify the mechanism our bearing would be used in, due to proprietary restrictions, but indicated it would be used as a safety mechanism.

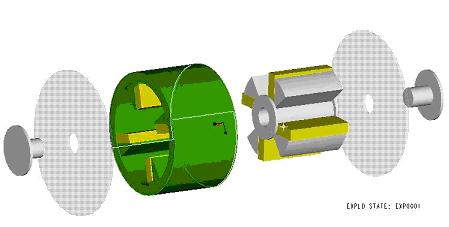

Sandia created a magnetic bearing prototype (pictured above) and wanted our design group to come up with our own concept to improve the bearing's performance.

This is our final design concept. The outer shell and inner rotor contain magnetic material placed so that movement is restricted and maximum repulsive force occurs when it is fully extended. The side walls (made of plexiglass in our prototype) are connected to the outter shell and the coupler pegs are connected to the inner rotor.