|

PROBLEMS AND SOLUTIONS |

||

|

Problems and Solutions

|

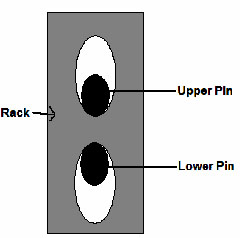

Some of the main problems we encountered throughout this project were: * The ratchet used to rotate slightly due to the large forces it was subjected to. We drilled more holes in the ratchet and inserted small tension pins to fix it in the correct position. * The pawl wasn't returning to its initial position after being released. The compression spring we were using was to small and started to deform due to the load. A larger, stronger spring solved the problem. * By buying the rack with the holes already drilled, we definitely save some tedious machining work, but the holes in the rack are not circular, they have more of an elliptical shape. In order to use this rack, we had to adapt our pins so they could constrain the sleeves in every direction. By having two holes in the sleeve, and by creating a modified pin it was possible to use the rack in our design. The modified pin consists of two original pins spaced out with the same spacing as in the sleeves, and welded together at the top.

Modified pin and rack. With two pins and two holes in the sleeve, any desired height can be achieved in increments of 2 inches. The sleeve is completely constrained after the modified pin is inserted.

|