IGVs

Compressors require a means of controlling the capacity, when the speed drive is constant. The most common way to alter the capacity is to create a swirl in the refrigerant prior to entering an impeller. Inlet guide vanes, IGV, also referred to as pre-rotation vanes, produce the swirl. To throttle the flow, IGV rotate from being parallel to the flow all the way to being perpendicular. The flow is throttled to reduce the work needed at the desired air outlet conditions. This decreases the input work and improves the specific power. The IGV can also increase the flow by pre-rotating the flow against the impellers direction of rotation.

Performance:

- The efficiency increase from having IGV on only the first stage decreases as the number of compression stages increase

- The more precise the IGV are adjusted, the greater their impact on performance will be

- IGV are only beneficial when the compressor is not fully loaded

- IGV benefit the power input when partially loaded

- IGV at over-throttle can increase the flow rate

- IGV must be positioned as to not allow harmonics between the IGV and impeller

- IGV don't increase turndown, they enhance efficiency during turndown

IGV main benefit is the turndown control. IGV reduce the power input when the compressor is running at a flow rate lower than that of its design.

There are other ways to control the flow such as;

- Butterfly Valves

- Variable Speed Drive Compressor

- Suction Throttling

- Impeller Throttling Sleeve

- Adjustable

Diffuser Vanes

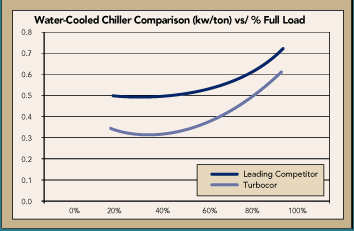

IGV are just more efficient at turndown control. This other methods however, can be combined with IGV to create an even higher efficiency, like the compressor that Danfoss Turbocor builds, maintains and designs. Danfoss Turbocor’s compressor is a combination of the variable speed drive and IGV. This leads to higher efficiency than the leading oil-flooded screw compressor.

|

Fig. 01 - 75 Ton Danfoss Turbocor Compressor vs. Leading Oil-Flooded Screw Compressor. |

As

can be seen in the

above figure, Danfoss

Turbocor’s compressor is more efficient

at

100% of the load. However, at 20-60% the Turbocor compressor requires

significantly less power, thus leading to a much higher

efficiency and the need for IGV’s.