Our senior design group was given the objective of designing a precision reflector surface adjuster.

This detachable mechanism would be developed as a substitute for the method of manual reflector adjustment.

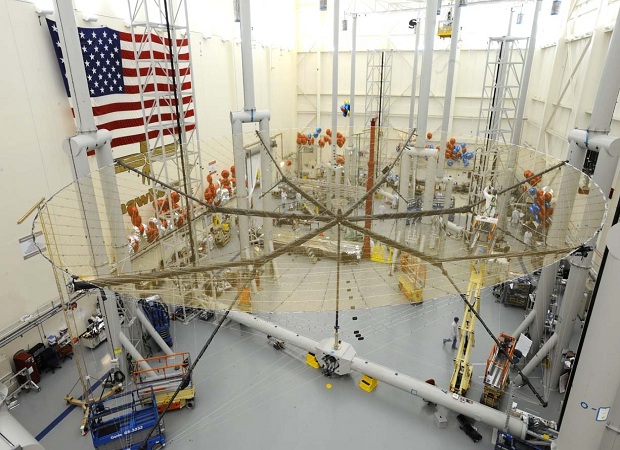

Current adjustment methods involve manual interaction with the mechanism used to tighten or loosen the yellow chords extending between each rib shown in the picture to the left.

After initial adjustments have been made, measurements are taken to determine the accuracy of the surface geometry.

Additional adjustments may be required.

This process is carried out at each of around 137 mechanism locations for a reflector similar to the one shown.

Our senior design group was given the objective of designing a precision reflector surface adjuster.

This detachable mechanism would be developed as a substitute for the method of manual reflector adjustment.

Current adjustment methods involve manual interaction with the mechanism used to tighten or loosen the yellow chords extending between each rib shown in the picture to the left.

After initial adjustments have been made, measurements are taken to determine the accuracy of the surface geometry.

Additional adjustments may be required.

This process is carried out at each of around 137 mechanism locations for a reflector similar to the one shown.

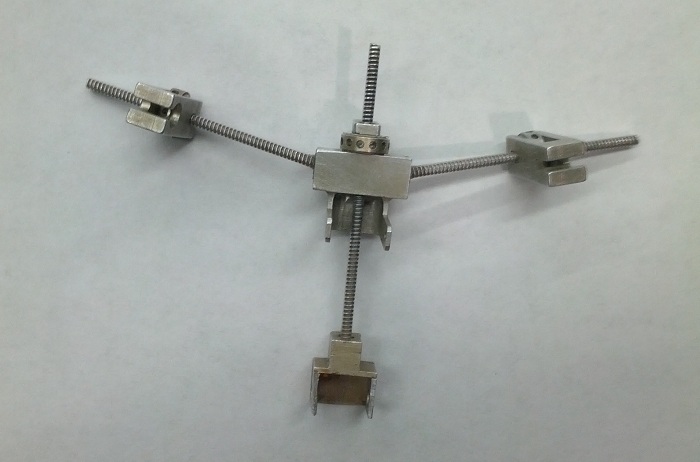

Our mechanism would be a precise, time saving device that would allow adjustments to be made wirelessly. Each individual unit would consist of three individual motors used to drive the gears that would tighten or loosen the chords attached to the reflector panel. This would eliminate the need to walk around the reflector for every single adjustment necessary.

This is an actual model of an older adjustment mechanism