Background

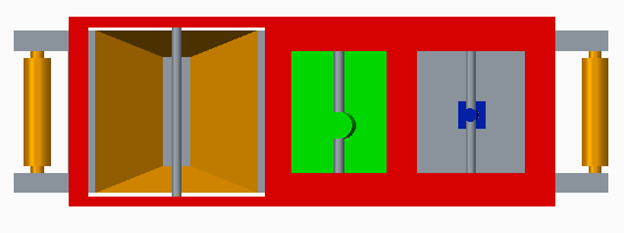

There

is a new material, developed by FMC Lithium Corp., that has been

experimentally tested to improve the first cycle efficiency and

longevity of batteries. This new material is stabalized lithium metal

powder. Our project is to develop a prototypal machine to evenly

distribute this SLMP onto an electrode. Although there is a wet method

for applying this SLMP in existance already, we aim to develope a dry

method to disperse the metal powder, which has never been successfully

done in the past. In short, our approach is comprised of a funnel being

agitated by vibration over a conveyor belt to move the electrode sheet

back and forth until the coating is even. Being a new and highly

reactive

material, there are many constraints to this project; one of the most

important being that the machine has to operate within a dry room for

the lithium powder will react with any moisture in the air.

Additionally, inside the dry room, experimenters should always be

wearing a face mask and goggles for the lithium can be hazardous if

inhaled or ingested. A tour of the dry room and more information on our

project can be found around this website on the contact and information

tab.

There

is a new material, developed by FMC Lithium Corp., that has been

experimentally tested to improve the first cycle efficiency and

longevity of batteries. This new material is stabalized lithium metal

powder. Our project is to develop a prototypal machine to evenly

distribute this SLMP onto an electrode. Although there is a wet method

for applying this SLMP in existance already, we aim to develope a dry

method to disperse the metal powder, which has never been successfully

done in the past. In short, our approach is comprised of a funnel being

agitated by vibration over a conveyor belt to move the electrode sheet

back and forth until the coating is even. Being a new and highly

reactive

material, there are many constraints to this project; one of the most

important being that the machine has to operate within a dry room for

the lithium powder will react with any moisture in the air.

Additionally, inside the dry room, experimenters should always be

wearing a face mask and goggles for the lithium can be hazardous if

inhaled or ingested. A tour of the dry room and more information on our

project can be found around this website on the contact and information

tab.

There

is a new material, developed by FMC Lithium Corp., that has been

experimentally tested to improve the first cycle efficiency and

longevity of batteries. This new material is stabalized lithium metal

powder. Our project is to develop a prototypal machine to evenly

distribute this SLMP onto an electrode. Although there is a wet method

for applying this SLMP in existance already, we aim to develope a dry

method to disperse the metal powder, which has never been successfully

done in the past. In short, our approach is comprised of a funnel being

agitated by vibration over a conveyor belt to move the electrode sheet

back and forth until the coating is even. Being a new and highly

reactive

material, there are many constraints to this project; one of the most

important being that the machine has to operate within a dry room for

the lithium powder will react with any moisture in the air.

Additionally, inside the dry room, experimenters should always be

wearing a face mask and goggles for the lithium can be hazardous if

inhaled or ingested. A tour of the dry room and more information on our

project can be found around this website on the contact and information

tab.