Development of a Compact Pressure Sensor for Multi-Layer Insulation in a Vacuum

Multi - Layer Insulation (MLI) is a special type of high performance thermal insulation system that

is utilized on various

spacecraft, satellites and probes. It consists of alternating layers of

ametallized polymer film such as "Aluminized" Mylar and a low conductivity spacer material like

Dacron. The reflective film layers effectively act as radiation shields, preventing radiant energy

from penetrating the MLI. The spacer which has a netting pattern ensures that no additional heat is transferred through solid conduction. However, at a certain pressure level, gaseous conduction

and convection start to become significant and could dominate radiation heat transfer.

Thus, it is important to keep track of the pressure in the interstitial region between layers.

The goal of this project is to design and implement

a compact pressure sensor to fit between layers of MLI.

It is expected that the sensor can measure a large pressure range all the way from atmospheric (101 kPa) to

roughly vacuum pressures (10^-2 Pa). The requirements set forth by our sponsor are that the sensor is minimally

invasive to the MLI's structure, and that it can operate in a temperature range of 77 K to 300 K. The desired

sampling rate is 1 sample per second. Another main objective of this project is to minimize the power

consumption and heat produced by the device.

It is expected that the sensor can measure a large pressure range all the way from atmospheric (101 kPa) to

roughly vacuum pressures (10^-2 Pa). The requirements set forth by our sponsor are that the sensor is minimally

invasive to the MLI's structure, and that it can operate in a temperature range of 77 K to 300 K. The desired

sampling rate is 1 sample per second. Another main objective of this project is to minimize the power

consumption and heat produced by the device.

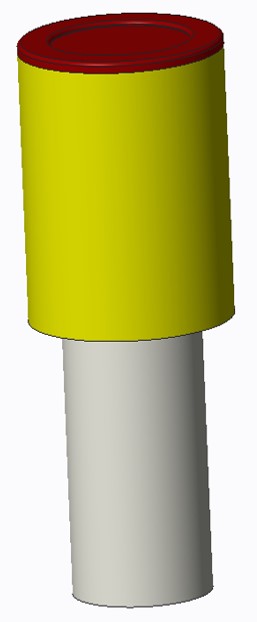

Conceptual designs

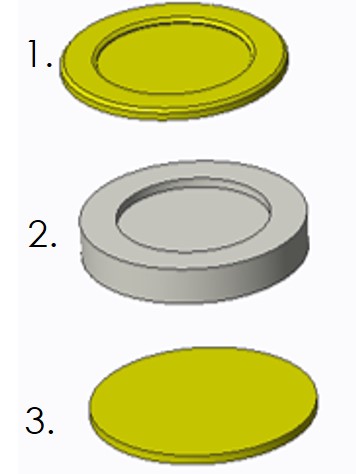

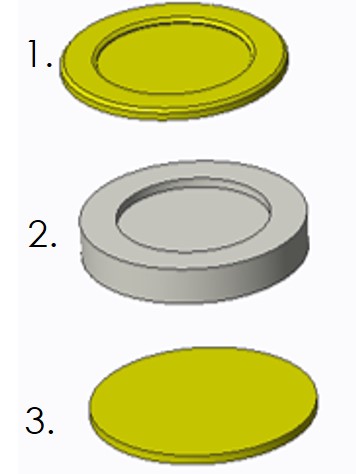

1. The first proposed idea is a variable capacitor that changes its capacitance based on an external pressure change.

The bottom plate of the capacitor is stationary and the top surface is a flexible diaphragm. It is doped with various

elements (like germanium and silicon) to increase strength and flexibility.

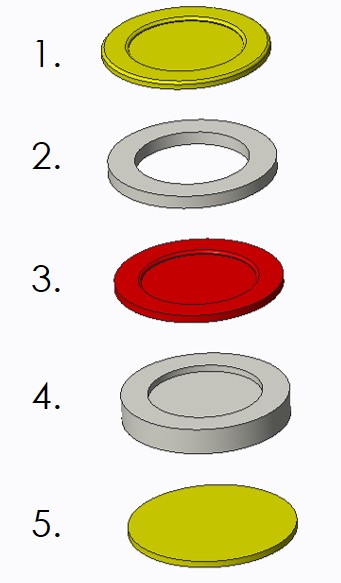

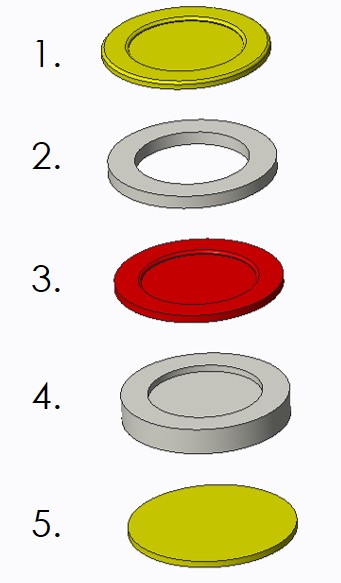

2. The second idea is an extension of the first. The Multi-Stage Capacitor would be able to read a low and a high

pressure range based on the stiffness of the red and yellow diaphragm.

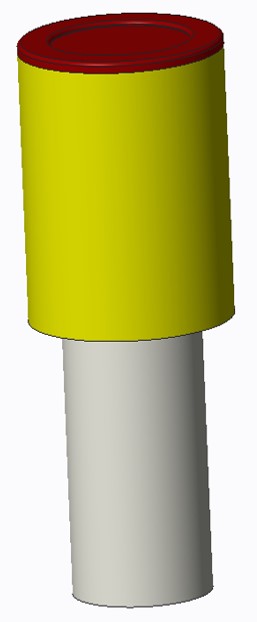

3. The fiber optic design is by far the most versatile because it can measure a very large range of pressures and is

useful even in rugged and low-temperature environments. A light source sends a signal down a fiber-optic cable where

the intensity of the light reflected off a diaphragm is measured and compared to the original intensity and correlated

to pressure. Polarization, Wavelength Change and the Phase Angle are parameters that can be related to pressure

instead of light intensity.