Research

The two main systems that make up the Centennial Calendar are the power generation and the time-keeping mechanism. Since the calendar must be completely mechanical, research was conducted to better understand how currently existing mechanical power generation and time-keeping mechanisms work.

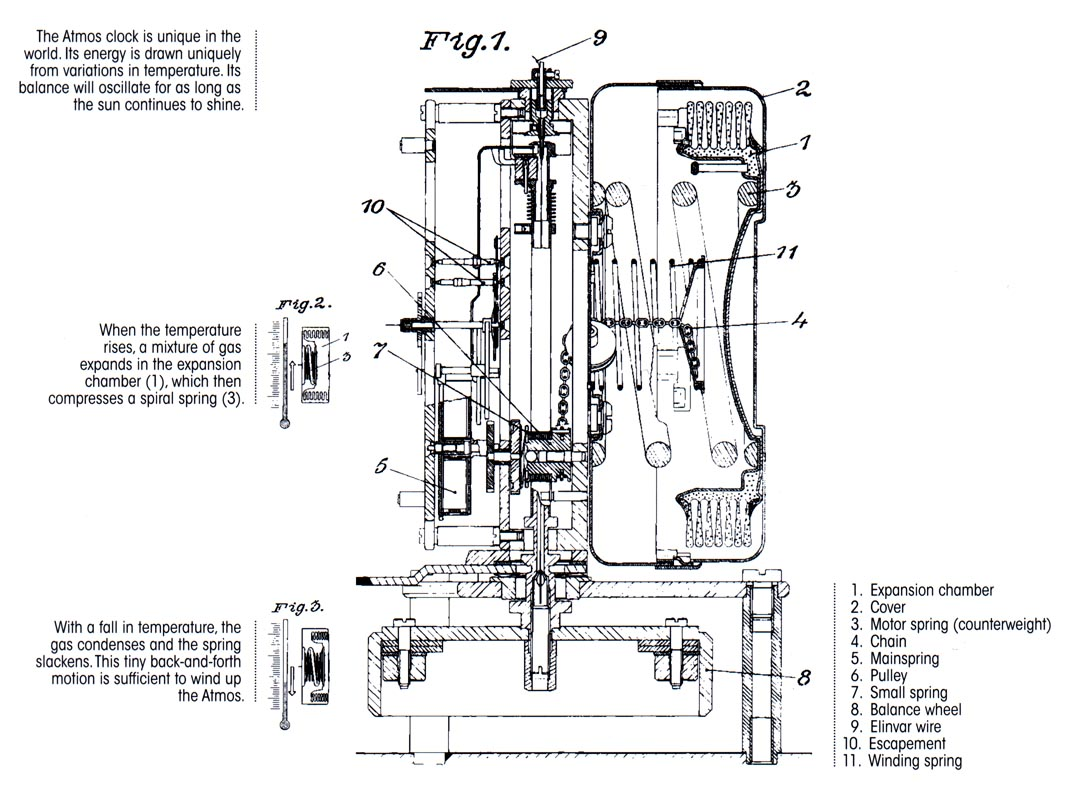

Atmos Clock

An Atmos clock is a mechanical torsion clock which requires no external power source to run. In other words, there is no need to wind the mechanism or reset a suspended weight by hand. The clock is instead powered by minute changes in atmospheric temperature. A semi-rigid pressure vessel, or capsule, containing some gas expands and contracts with changes in ambient temperature throughout the day. Modern Atmos clocks use ethylene chloride gas as the medium of expansion because it has properties of thermal expansion which allow it to expand and contract in changes of temperature as low as 1° C. This chamber of now-expanding gas is connected to a chain which winds the mainspring in the clock. The movement is similar to that of a bellows. The chamber slowly expands and contracts over the course of the day as the temperature changes. This reciprocating expansion and contraction of the capsule effectively winds the mechanism allowing it to sit unattended and unmaintained for many years at a time while still keeping an accurate time.

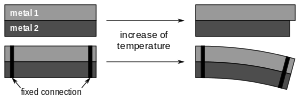

Bimetallic Strip

A bimetallic strip converts a temperature change into a mechanical movement. Generally, the strip is made of two different metals which expand at different rates under heat. These strips, most often steel and copper, are riveted or welded together. The differing rates of expansion force the strip to bend a certain way when heated and bend the opposite way when cooled. The metal with the higher coefficient of thermal expansion is the one on the outside when heated.

Bimetallic strips are already used in some clock mechanisms to keep the timekeeping mechanism accurate. A different usage of the strip in a clock is one similar to that of the Atmos clock. In this particular instance the strip takes the place of the semi-rigid pressure vessel. The strip, under oscillatory heating and cooling conditions throughout the day, will bend back and forth. This strip is attached to a chain which winds a torsional spring or resets a counterweight. Using changes in ambient temperature as a source of power generation is a potential solution because changes in temperature are consistent enough to cause the strip to move and the amount of energy harnessed by winding the mechanism or resetting a weight is more than enough to power the clock movement for a day.

Rainwater Collection Device

One way we can utilize the power of rain is by creating a type of reservoir which could collect and catch the rain as it falls. This reservoir can be connected through a ratchet-like device which in turn can be attached to a main spring, which runs the mechanism. The reservoir can act like refillable weight, with the rain filling up the reservoir to create the weight. The reservoir could be on a seesaw like device which connects via an axle to the ratchet. One side of the device would be the reservoir and the other side would be a small weight or handle. This will act like a wind-up key, where the spring is wound when the water fills the reservoir enough to turn the axle connected to the spring. As the spring continues to unwind and run the entire system, the reservoir turn-key will slowly rotate back around, and the water will either fall out or evaporate. Once the turn-key device rotates back around, rain will eventually fill up the reservoir again and the process will repeat, continuously providing energy into the system over the course of its lifetime.

While using a naturally reusable power source is a potential solution, there are a few difficulties which might be encountered when implementing this concept. While rain patterns can be somewhat predicted using current technology, these predictions are not always accurate. The main spring will have to store enough energy to run the calendar during the periods between rainfall, or there will need to be another power source for the calendar to use if there is no rainfall for a long period of time. Using water also means that part of the system will need be open to the elements. This could potentially cause rust or leaks into the rest of the system, if the system is not sealed properly. The turn-key device will also have to be strong enough to withstand storm or hurricane rain and wind since it must be exposed to the elements. These are the things we are considering before implementing this concept.

Magnet Return System

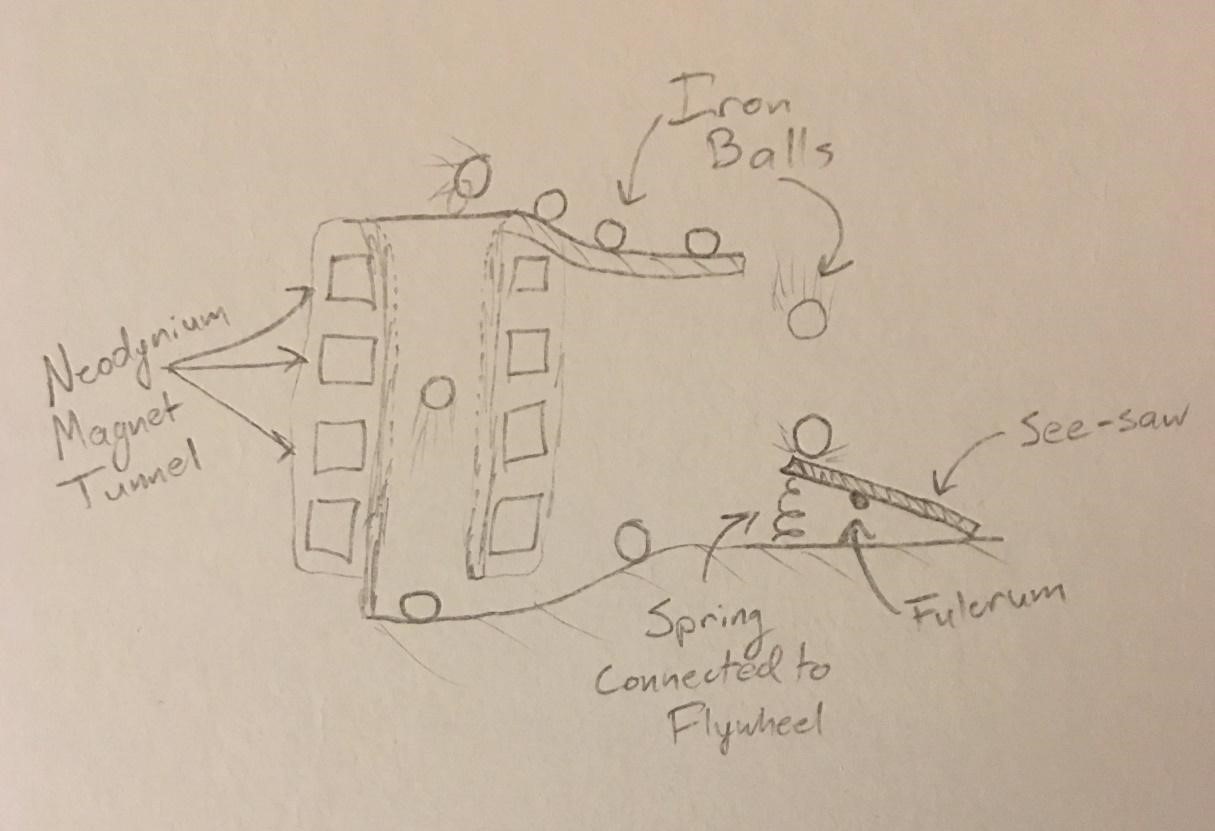

Knowing that permanent magnets, such as neodymium, retain their magnetic prowess for extreme lengths of time, a system that utilizes these permanent magnets to raise the height of ferromagnetic objects seems promising. These raised ferromagnetic objects could then be dropped in order to harness their kinetic energy, and then be raised back up to their original height by the permanent magnets in order to be dropped again. This cycle could theoretically continue endlessly, allowing for a near infinite energy source, at least until the permanent magnets lost their magnetism.

Neodymium magnets in particular lose their magnetic prowess at a rate of around one percent over the course of 100 years. Therefore, they would likely be the permanent magnet utilized if a system such as the one described above were to be implemented. The ferromagnetic objects would be heavy in iron content so as to be easily influence by the magnetic fields created by the neodymium magnets, and their shape would be spherical so frictional forces of the moving object will be at a minimum. These iron balls would start at a raised height and be dropped onto a device that would store the kinetic energy, likely a seesaw type device that has a spring underneath the side of the fulcrum in which the iron balls would hit. This spring would be connected to a flywheel in order to extract and move this kinetic energy to the energy storage system of the Centennial Calendar for later use. After the balls fall and hit the seesaw, they would be funneled into a tunnel composed of neodymium. This tunnel would focus the magnetic field in the center of the tunnel and would pull the iron balls from the bottom funnel back to their starting point at the top of the device. Figure 3 roughly visualizes how this system would be laid out.

The main issue with this device which hinders it from being fully implemented, is its inconsistency with returning the iron balls to their starting location at the top of the device. Unless the center of mass of the iron balls could be perfectly aligned with the center of the magnetic field produced by the neodymium tunnel, they will shift to one side of the tunnel and simply stick to the magnets. This will completely stop the mechanism, not allowing for any energy to be harnessed. Since this mechanism needs to run constantly for 100 years, the likelihood of the iron balls being attracted to the wall of the tunnel at some point due to an imperfect alignment is far too high to consider it as a reliable source of energy in the Centennial Calendar. Because of this, the magnetic return system will not be utilized within this project.

Perpetual Motion

The first wheel power source that we are researching is the flywheel battery. The basic concept of a flywheel battery is a cylinder which is suspended on an axle, as can be seen in Figure 4. A flywheel can be spun at high speeds in order to create or store energy. In essence, a flywheel is an electromechanical battery. Currently, flywheels spin using a motor-generator which both spins the wheel and collects the energy output. Advancements in technology have allowed the flywheel design to be more optimized through the use of vacuums and magnetic bearings. This has led to some experimental flywheels running up to two years without additional energy input.

Since the flywheel battery requires a motor-generator to convert mechanical energy into electrical energy and our system cannot have any electrical components, the electromechanical version of the flywheel has been discarded as an option. The concept of the flywheel, however, has led into the next phase of research, which is perpetual motion. The idea of the perpetual motion wheel is similar to the flywheel battery in that a wheel is turned in order to create energy, but the motion of the wheel is continuously powered by its own mechanical means.

One of the early perpetual motion wheels that has been designed is the Bhaskara wheel, which can be seen in Figure 5. The Bhaskara wheel is made up of spokes attaching from the center of the wheel, with tubes filled with a dense liquid attached to each spoke. These tubes are all placed at an angle to the wheel and are only about two-thirds of the way filled with the liquid. After an initial spin to start the rotation of the wheel, the liquid falls to the bottom of the tubes on one side of the wheel as it rotates. This provides the force needed to keep the wheel spinning. As the wheel continues to spin, the liquid settles to the bottom of the tube until the tube is tipped again, after the wheel completes another revolution.

This version of the perpetual motion wheel has failed, as have many of the other designs explored afterwards. One example being the Articulated Arm Wheel, as depicted in Figure 6, which uses hinged weighted arms, instead of liquid, to swing the wheel every revolution. In the end, none of these perpetual motion wheels work because the system can never output more energy than was initially input into the system, or in other words, there is no gain in the net energy. In addition, neither the shifting masses nor gravitational force do any net work on the wheel, and therefore, the wheel will eventually stop, no matter how well it’s designed. It is for this reason that this design has also been discarded.

The last perpetual motion device that has been researched is the Free Energy Magnet Motor. This idea is, again, similar to the flywheel, in that it can be used to produce electrical energy, but like the Bhaskara Wheel, it can theoretically run forever. The Free Energy Magnet Motor can be created by attaching small magnets, with one or alternating poles facing outward, to a fan or a wheel with spokes. An example of how these motors are often portrayed online can be seen in Figure 7. When a larger, standalone magnet of the opposite pole is brought close to the fan, the small magnets are repelled by the larger magnet and cause the fan to spin. This has turned out to be mostly an online hoax, as the small magnets, no matter how strong or how precisely they are positioned, will always be attracting the larger magnet at some point in the revolution, which quickly brings the fan to a stop. It has been discovered that no instance of perpetual motion has ever been successfully implemented, so the entire concept of perpetual motion has been completely disregarded.

House of Quality

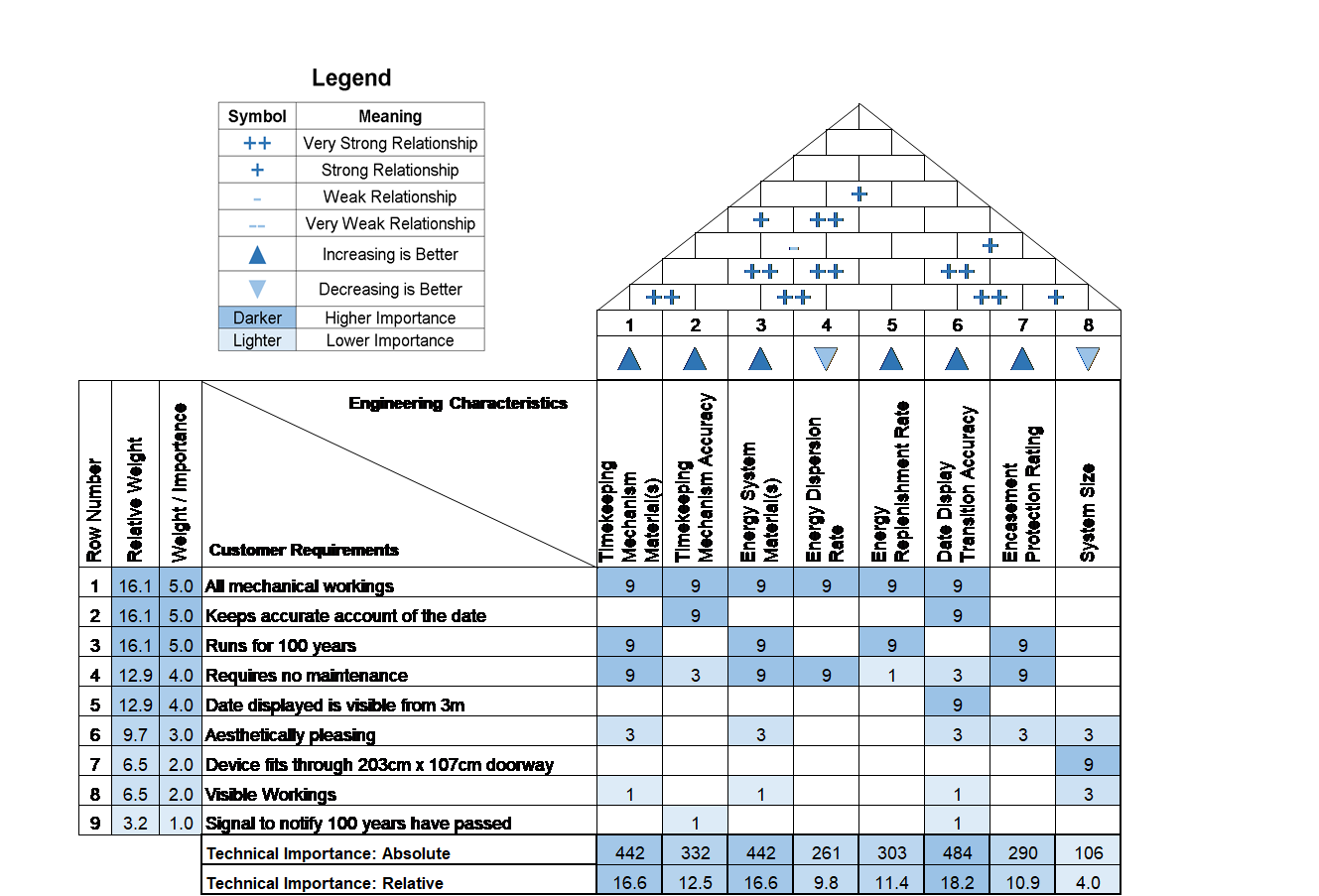

In order to determine which of the subsystems listed in the functional decomposition and which of their respective characteristics were the most important to the success of the project, Team 18 created a house of quality

From this house of quality, it was determined that a strong emphasis needs to be put into picking the correct materials for both the timekeeping mechanism and the various components of the energy system as a whole. This makes sense that material selection is such a crucial portion in the success of the project, as the device must run for 100 years without degradation of the components in order to ensure the device can last such a length of time. Likewise, a strong emphasis needs to be put into perfecting the accuracy of the date display, as a calendar that cannot provide the correct date is a useless calendar.

Following these three crucial aspects of the device, the house of quality also tells us that we need to focus on the perfecting accuracy of the timekeeping mechanism accuracy and energy replenishment rate next. The accuracy of the timekeeping mechanism goes hand-in-hand with the accuracy of the date display, the most crucial aspect of the entire device, since the date will change based on information transferred from the timekeeping mechanism of the device. It is then crucial to ensure enough energy is replenished as time goes on else the device can run out of energy and stop working. Energy replenishment rate coincides directly with the energy dispersion rate, the next most important criteria to focus on. If the device uses up energy quicker than the energy can be replenished, failure of the device will be inevitable.

According to the house of quality, two of the least important factors to focus on are the encasement protection rating and the actual size of the system itself. This makes sense, as if we have a perfectly weather-proof encasement that can withstand the Florida elements for 100 years, but no working calendar to put inside of it we will have nothing more than a glorified box. Likewise, the size of this box is unimportant to the overall success of the project. It will be more important for Team 18 to focus on creating a working, self-sustaining timepiece than to ensure the encasement for the workings is reasonably sized and able to last outside in the Florida elements for 100 years.

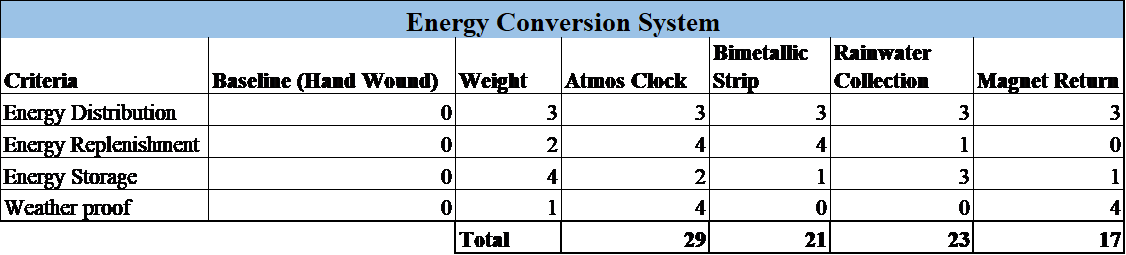

In order to properly determine which of our energy conversion concepts are optimum we first had to determine the criteria in order to rate each system. In order to determine this, we used a decision matrix. These criteria were determined from the functional decomposition. Each system must have energy distribution, replenish that energy, store it, and be weather-proof in order to allow the system to operate under normal conditions.

A baseline had to be determined as well in order to rate each system off of. Considering the absence of an existing concept to improve on, a generic hand wound energy system was used as the baseline. This baseline was given a rating of 0 in each category to show that each subsequent energy conversion concept is an improvement to the existing hand winding method. Each criteria is then given a weight, the highest weight being the energy storage because storing the energy produced is paramount, and the lowest weight being the weather proofing because the production and sustainability of energy is more important. The concepts are then rated for each criteria from 0 to 4. That number is multiplied by the weight of the criteria to come up with a final value. These values are added up for each concept to determine the totals. Based on the given weights of each criteria and the how well each energy system fulfills those criteria from 0 to 4, 4 being the highest weight, a higher total value means the system fulfills the criteria more effectively. From the decision matrix, it can be determined that the Atmos clock is the most effective model as an energy conversion system

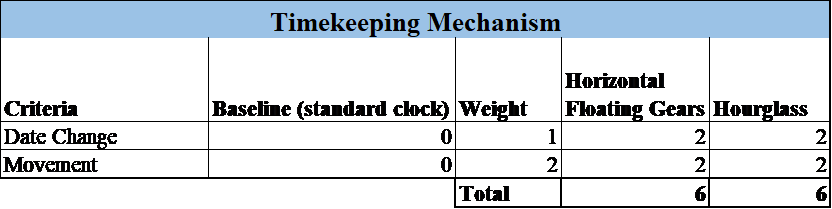

The timekeeping mechanisms were rated in a similar fashion. A standard clock is used as the baseline and the movement is given the highest weight because the mechanism must move in order to operate. The concepts rated are the horizontal floating gears and the hourglass. Both concepts were given the same rating. However, we determined that the most important concept and the one that we will likely pursue is that of the horizontal floating gears. This is due to the consistency inherent in solid gears and potential inaccuracy associated with a fluid keeping time in the hourglass.