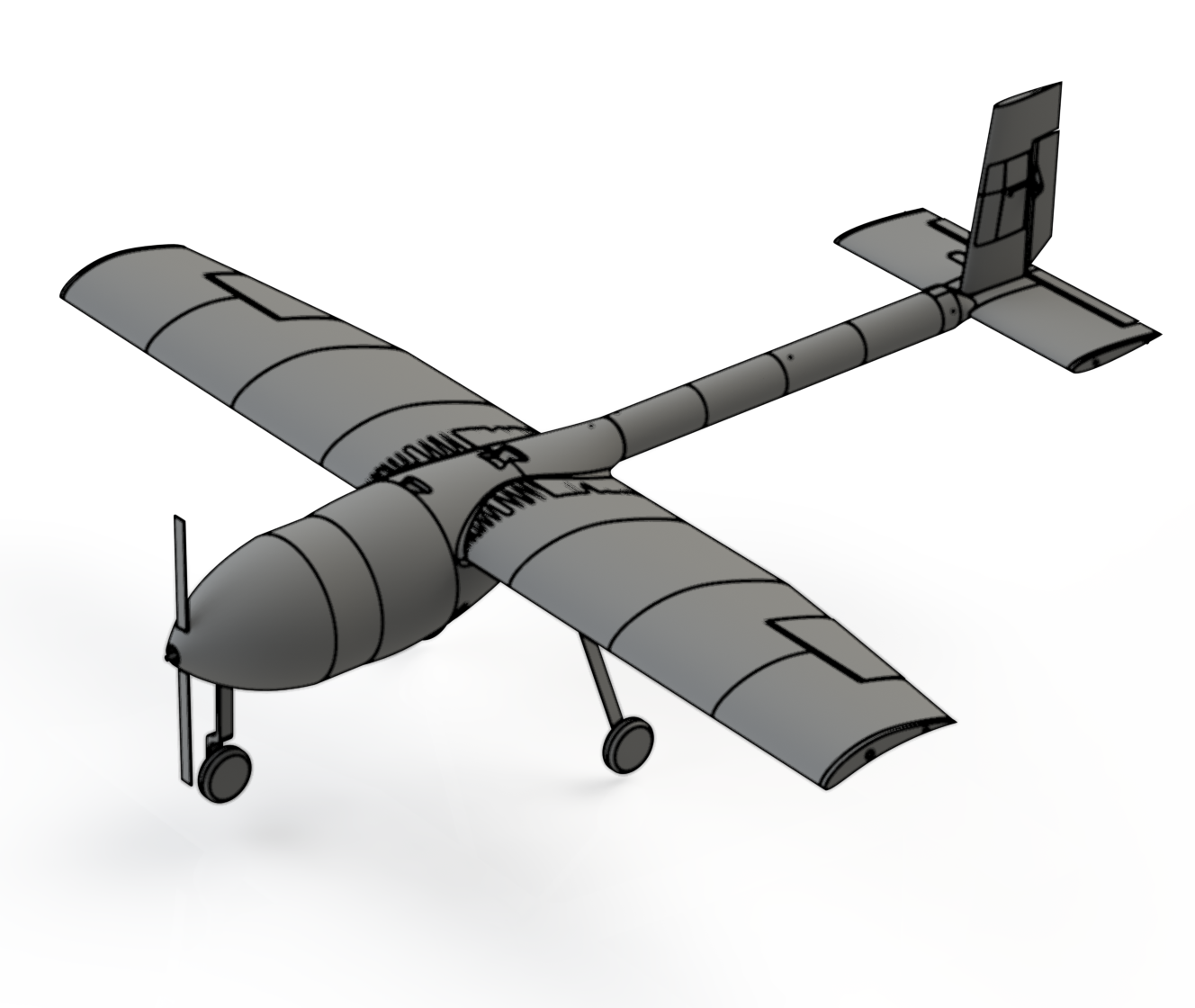

Radio controlled (RC) airplanes provide a way to push the boundaries of airplane design. The Society of Automotive Engineers (SAE) Aero Design competition is an event for college students that challenges them with designing an RC airplane fit to carry out a task. In 2020, the competition wants teams to build a short takeoff and landing airplane that can carry cargo. To meet competition requirements, our airplane can carry a size five soccer ball, one pound of cargo, and takeoff within 100 feet. Our airplane achieves this takeoff distance by using a unique airfoil for the airplane’s six-foot wing. Our airfoil has a high amount of lift at low speeds.

To be innovative, our five and a half foot long, 15-pound airplane is mostly constructed out of light weight PLA filament, a 3D printing material. This material is 50% less dense than regular PLA filaments. The lightweight filament helps us reduce the total weight of the airplane while still using additive manufacturing. The lighter our airplane is, the more cargo the team can carry, and the more points the team can score at competition. RC airplanes are typically made from balsa wood and foam which are easy to work with. 3D printing challenged us to create an airplane that is competitive with airplanes made from these standard RC airplane materials. Our airplane is made from modular parts which make it easier to repair and assemble than a traditional RC airplane. However, this also presented a challenge as parts had to be designed to be 3D printed and printed within a confined area. We aim to showcase how additive manufacturing can be used in the aerospace industry.

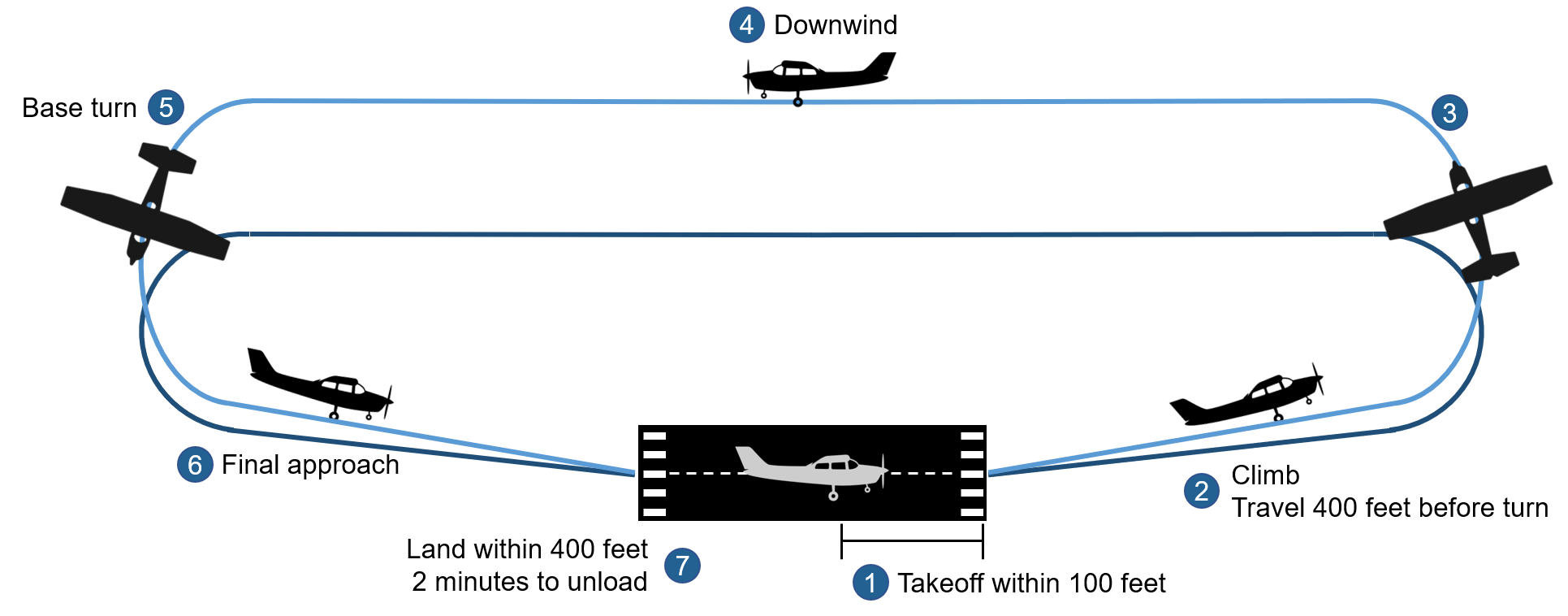

The following diagram shows the circuit that the airplane must complete at the competition.

✓

Manufacturing of the wings, boom tail, and vertical & horizontal stabilizers is completed.

✓

Team presentation of Virtual Design Review 4, showcasing our progress manufacturing the wings, boom, and tail of the airplane.

✓

Manufacturing of the fuselage, including cargo bay and electronics housing, is completed. The team will use this time to confirm the physical location of the center of gravity to determine placement of the landing gear.

✓

Team presentation of Virtual Design Review 5, showcasing our airplanes final design assembly as the team prepares to leave for competition in the days following.

✓

Functional airplane assembly is completed and ready to fly.

✓

The final wdays before the SAE Aero Design East competition will be used to make any necessary adjustments and prepare the airplane for competition.

✓

Fly high or bust! The team attends the SAE Aero Design East competition to represent the FAMU-FSU College of Engineering by competing with their regular class airplane.

✓

Following competition, the team will take time to record the competition outcome in the operation manual and reflect on their performance. We will also use this time to work on writing our conference paper to submit to [insert organization name].

✓

The operation manual will be submitted for evaluation. This manual includes relevant design documentation, assembly, operation, and repair instructions.

Team presentation of Virtual Design Review 6, showcasing our airplanes final design assembly and outcome of attending the SAE Aero Design East competition.

Nearing the end of the semester, the team will focus on completing and submitting final project documentation such as the conference paper to IEEE and complete evidence manual.

The team will showcase the airplane, even if damaged from flight at competition, at Engineering Design Day at the FAMU-FSU College of Engineering.

Update: Due to COVID-19, this event got cancelled.

Spring 2020 Graduation Ceremony for FSU Electrical & Mechanical Engineering students.