April 7 at 8 AM

FAMU-FSU College of Engineering

2525 Pottsdamer St, Tallahassee, FL 32310

United States

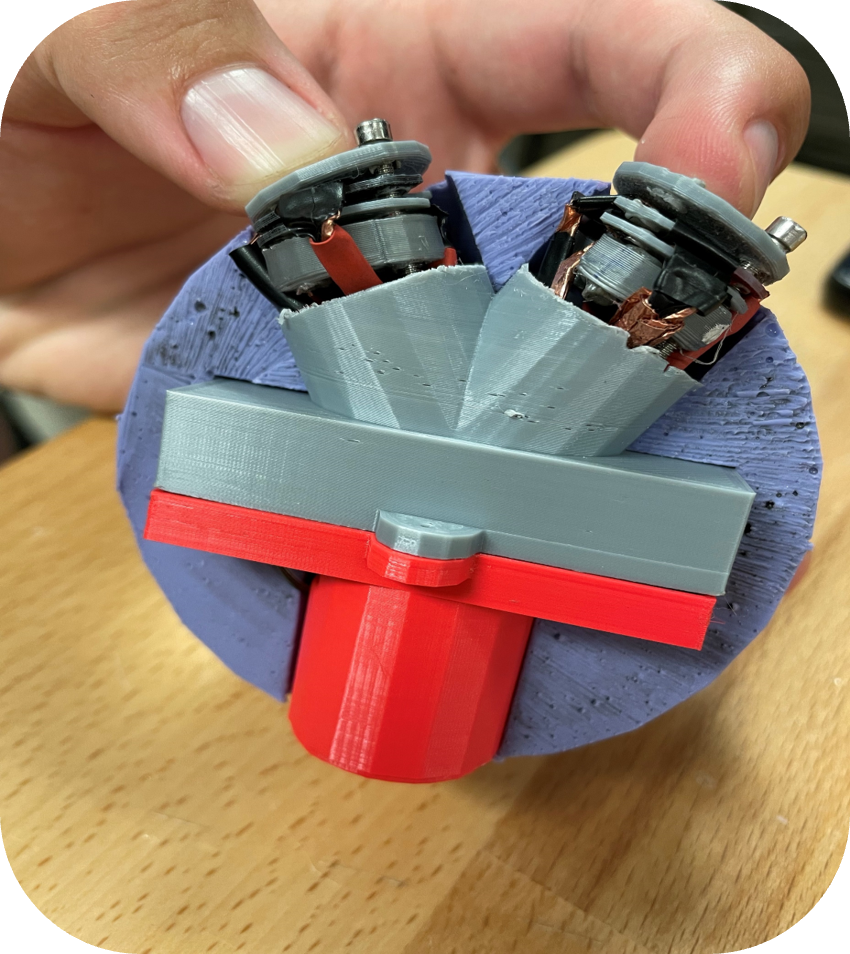

The group's main design consists of a 3D printed structure which houses the main components of our design: arduino BLE nano, battery, and both sensor stacks. One sensor stack is capable of monitoring the dynamic forces from the index finger and the other monitors the dynamic forces from the middle finger during a pitch.

The group designed a custom 3D printed mold which was used to pour a gravity mold. The casting material used was a silicon rubber due to its high tear strength and it had comparable density to rubber baseballs sold in today's market.

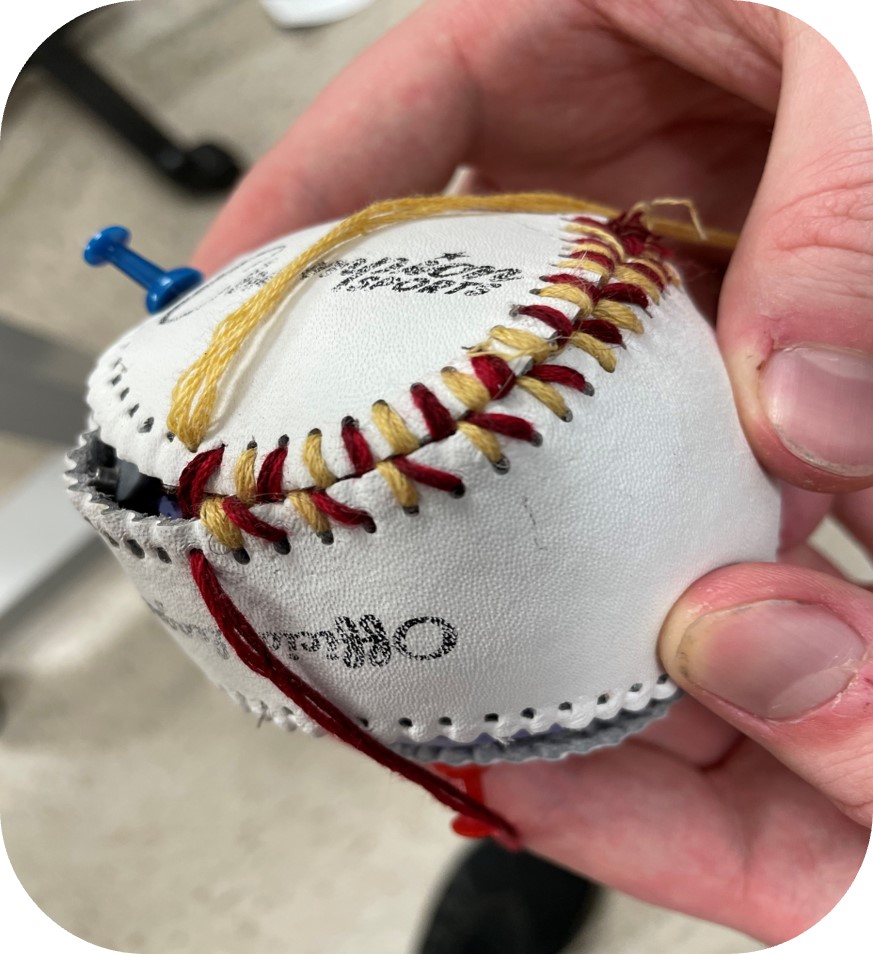

After the mold cured for 6 hours, the team extracted two half shells which allowed for our components to be placed inside (as seen in picture to the left and below).

To ensure the ball had a similar feel to an original baseball, the team hand stitched a leather cover over the rubber core.