Danfoss Turbocor manufacturers compressors for use in various applications. These compressors spin blades using a special magnetized shaft to cut down on friction. Currently, checking the quality of the magnetized part is tricky and requires too much manual work. Therefore, Danfoss requests that Team 513 create a device that can automatically read the magnetic flux, which is a measurement of the total magnetic force that passes through the shaft. Danfoss hopes this project will free up workers, lower production errors in the shafts, and save money. The nickname of the device is the AFR (Automated Flux Reader), and it is designed to measure the magnetic flux of the shafts automatically and precisely.

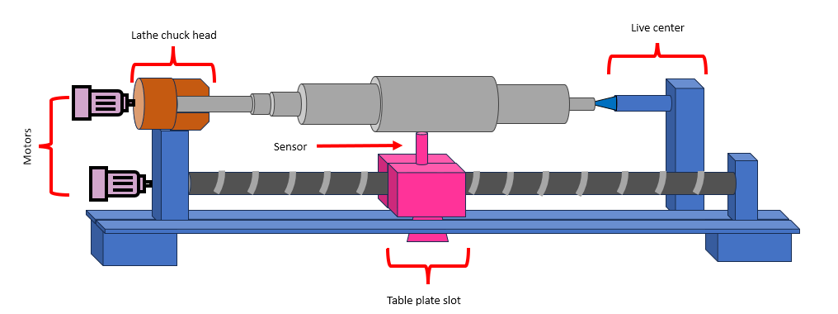

The AFR is an electronic device with two main duties. These are to move a sensor across the length and circumference of the shaft’s magnetic region. To move the sensor along the circumference of the shaft, the AFR secures the shaft in a horizontal position while spinning it using a motor. Then, the flux sensor travels the length of the shaft via a rail system that utilizes a separate motor. The spacing between flux measurements needs to be, at most, five millimeters apart. This results in the AFR taking about 2,500 measurements per test. A programmed controller manages these functions to obtain flux measurements over the shaft’s magnetic region.

The AFR helps Danfoss test shaft quality in a way that was not possible before. It gives more reliable data than before, making measurements more accurate and consistent. Additionally, AFR is easier for users because they only need to set parameters at the beginning and load the shaft. Then the AFR will automatically plot the data onto graphs. The AFR will continue to help Danfoss with improving their shaft designs for years to come. .

The objective of this project is to design a device that will be capable of fully measuring and recording the magnetic flux of compressor shafts in an automated way that allows for accurate measurements, repeatability, and less overall firsthand work for the operator.