|

|

Team CERN

Collaboration

with Romania

|

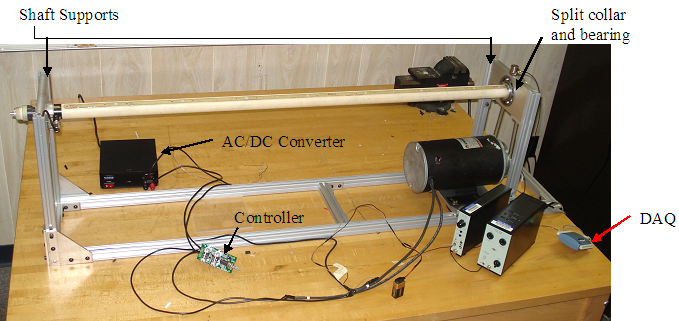

The team was able to build a

mechanically functioning machine. The split collar fits

almost perfectly on the shaft and in the bearing, and is

very well balanced (by virtue of its fabrication on a

balanced lathe). The delicate shaft mounts

appropriately on its supports without damage, and is

rotated very easily by the motor. The motor speed is

varied successfully with the controller built by the

team, and it receives enough power from the AC/DC

converter to rotate the shaft at and above the maximum

speed of interest (by visual inspection).

Figure – Complete set-up

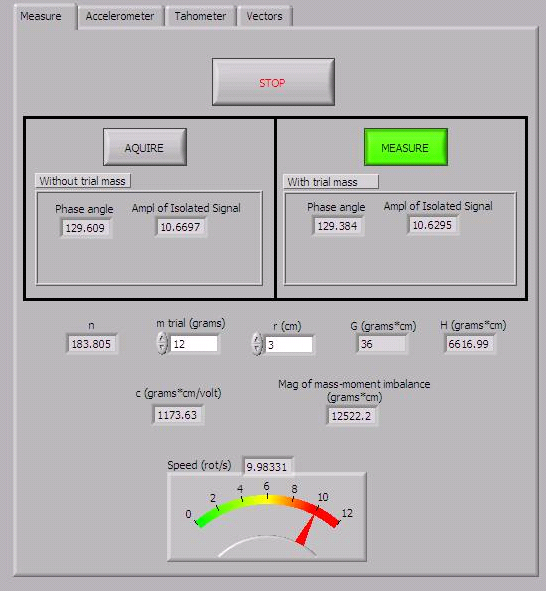

The analysis portion of the

software was a success as well. Tested with simulated

signals, it acquires the raw data from both the

tachometer and accelerometer, processes them through

filters and FFT, and performs all the required

calculations appropriately. Results are shown on the

Front Panel display on the Measure tab. See figures

below.

Figure – Front panel display showing operation buttons,

tachometer readout for rot/s, and inputs for trial mass

and radius of trial mass.

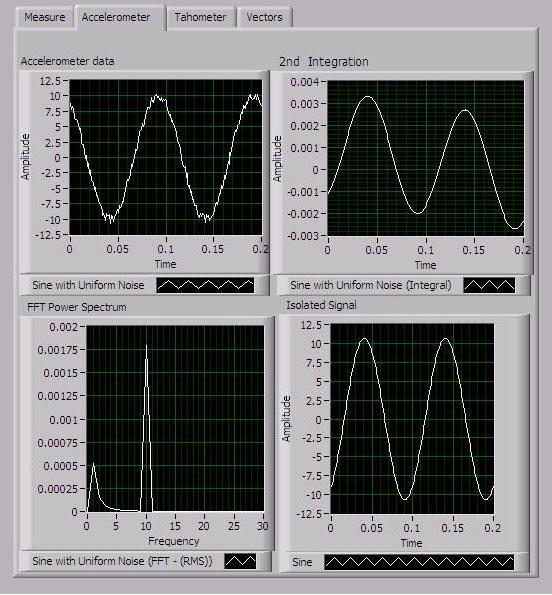

Figure – Graphs showing output for raw accelerometer

data with noise, FFT power spectrum, and the isolated

shaft signal with displacement amplitude (cm).

Figure – The tachometer tab shows the output of the

tachometer and the isolated shaft signal overlaid on

each other. This information is used to find the phase

of the signal.

Copyright

2007 CERN Team USA Group 13 Inc. All rights reserved. |