Project Overview

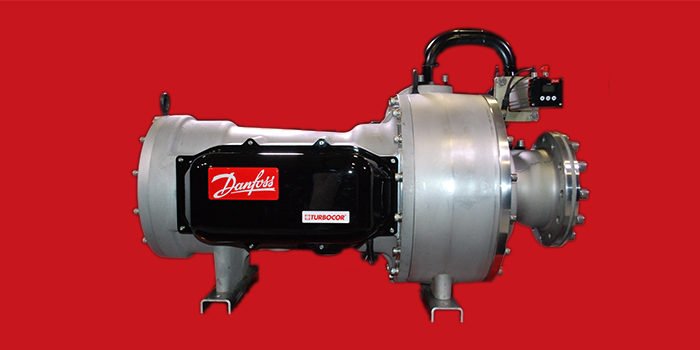

Danfoss Turbocor is a

world leader in the centrifugal compressor market. Their proprietary

maglev technology solidifies their compressors position as a top of

the line product. As developing technologies create competition for

Turbocor, they aim to add value to their product. To this extent,

Senior Design Team 5 has been tasked with the development of a

sensor package with the ability to determine real time efficiency.

Discussions with

Turbocor contacts as well as the teamís advisor Dr. Shih have

defined the direction of this project. The team is focusing its

major efforts into developing and integrating the sensor package to

work in conjunction with existing Turbocor monitoring systems. This

package integration is to be a stepping stone to the development of

a Failure modes prediction system in the future.

Adding the ability to predict failures will make the systems more reliable and stable. If the need for nonstandard maintenance can be predicted than it can be prepared for. This prevents undesirable downtime and possible catastrophic failures. Turbocor compressors are used in many different environments. While having the office HVAC fail would be highly annoying, if the same were to happen to a data center or other critical facility then results could be tremendously expensive. By predicting these possibilities they can be prevented. In addition, the extra gathered data can be used to improve future iterations through better understanding of their long term behavior.

We incorporated a Dalian Hipeak TDS100-F ultrasonic flow meter into Turbocor's existing framework. In addition a mounting system was designed to make installation easier and more flexible. The sensor output was exceedingly smooth and within 5% of what the current inline flow sensor was reading. For a full overview of our project please read the project Final Report.

Turbocor Compressor Basics

Danfoss Turbocor created the first magnetic bearing, variable speed compressor on the market. Below is a link to a video showing some of the features and key ideas behind these amazing machines.

Ultrasonic Mass Flow Sensors

Ultrasonic mass flow sensors use high frequency sound waves emitted and received by transducers externally mounted to a pipe. The time differential between upstream and downstream measurements along with other know parameters can determine the flow rate inside of the pipe. Check out our documentation or click the link below to view a brief video explaining the technology.