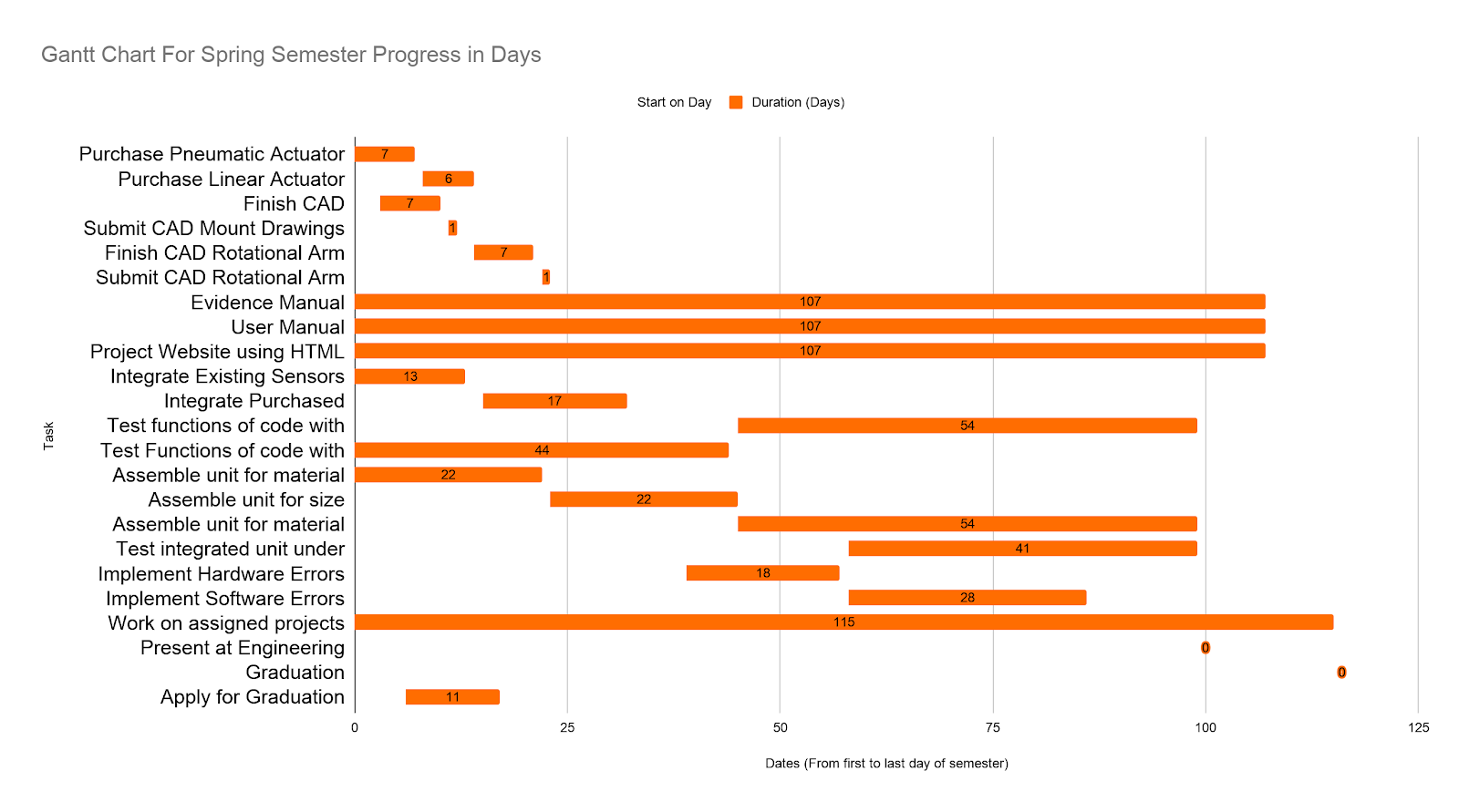

Project Abstract

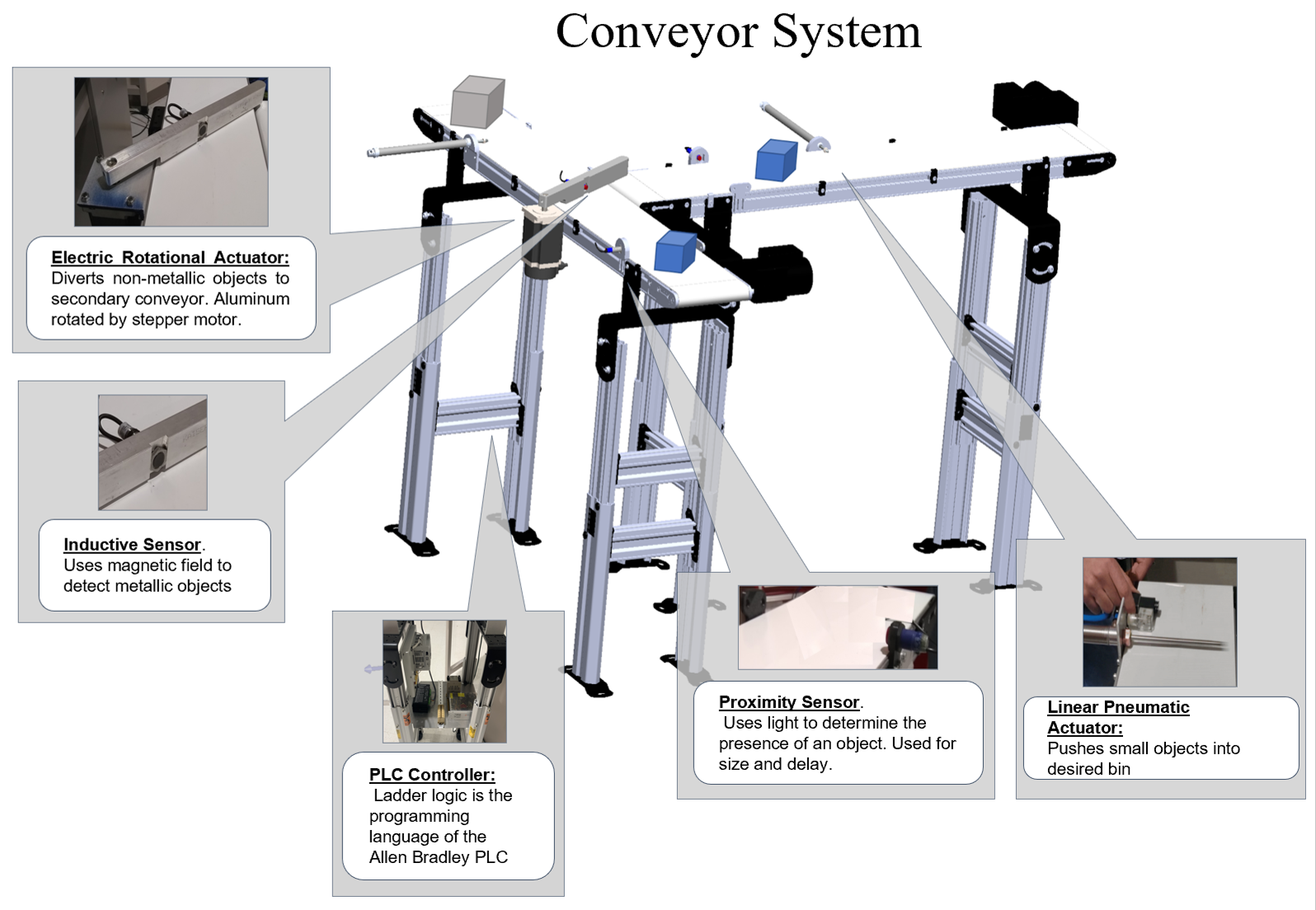

Tallahassee Community College Advanced Manufacturing Training Center students attend courses to learn to solve manufacturing plant issues. A common unit in these plants is an assembly line. Students in the advanced manufacturing courses benefit from hands on exposure to prepare them for future jobs. Senior design students at the FAMU-FSU College of Engineering must deliver a small-scale conveyor-based assembly line that sorts objects. They also provide 10 unique lab projects for Tallahassee Community College students to work on. The course teacher guides the students in the right path based on the lesson plans.

The assembly

line consists of two conveyor belts. Sensors, sorting arms,

and a programmable logic controller are the other parts.

Objects the assembly line sorts are plastic or aluminum cubes.

The cubes are different sizes. Cube size and material decide

how the unit sorts the objects. The brain of the unit is a

programmable logic controller. The controller reads in the

sensor data and decides how to sort the cubes. The sensors

control when the guide arm moves. A course book that lists

lesson plans for the 5 hardware and 5 software errors goes

along with the assembly line unit. This includes real world

assembly line problems such as blown fuses or bad sensors. The

issues could ruin the productivity of a plant if no one

addresses the issue quickly. Students become more comfortable

with the problems they face in class as they progress through

the course. The idea is that troubleshooting skills help

students get jobs which is the goal of the training program.

If students see the errors firsthand instead of just reading

about them it is more memorable. Overall, the assembly line

trainer serves to provide a learning aid to teach students to

troubleshoot common programmable logic controller issues.