Team 502’s mission is to provide a solution to

handling ceramic filters without introducing damage; our design will achieve

this by preventing visible damage at the location where the handler contacts

the filter’s outer walls.

Corning produces brittle, cylindrical ceramic filters

for vehicles with internal combustion engines to filter exhaust air. Throughout

production, these ceramic filters are at times subjected to damage when moved

from one manufacturing stage to another. Damage to these filters typically

occurs from crushing the filter’s skin, making the filters unusable. These

ceramic filters have varying sizes, with diameters ranging from 7.5 to 15

inches and weighing from 4 to 40 pounds.

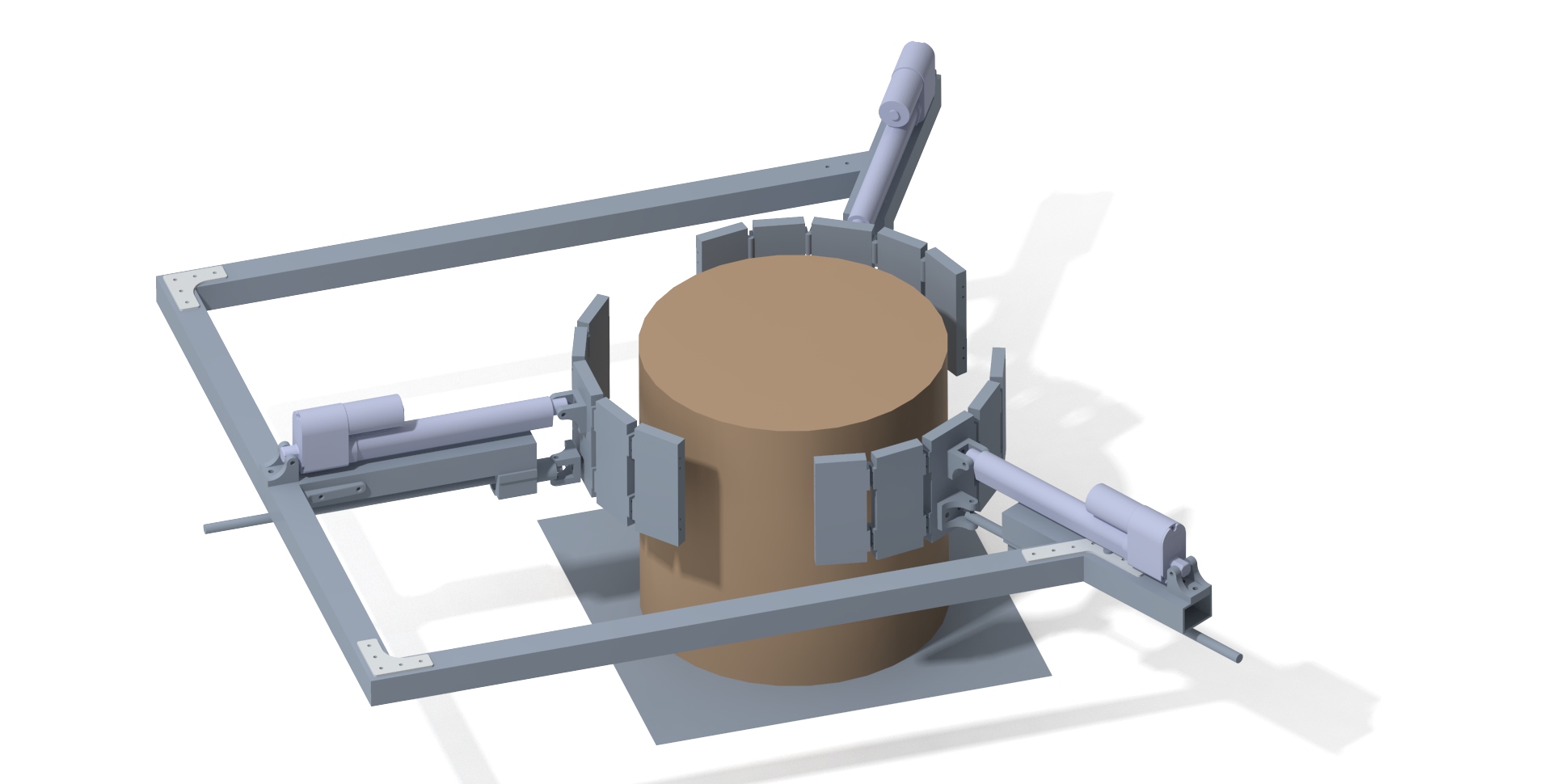

Our

handler design has three fingers that approach the filter’s surface in three

separate places around the filter’s circumference. The design is adjustable

depending on the size of the filter it is handling. There is compliant padding

attached to the design that contacts the filter’s surface to lessen the contact

forces applied on the filter. Force sensors indicate when the handler should

stop applying pressure, allowing for part movement. This procedure is quick and

consistent with the use of motors and a computer, making the design usable in a

lean manufacturing system. The linear motion of the padded three-finger design

also allows the handler to pick and place various sizes of these ceramic

filters with a controlled motion.

Corning has provided our team with part samples. Our

team will show the effectiveness of the design by evaluating the handler

performance with these sample filters. A successful test would result in the

handler not causing damage to the ceramic parts after grasping and moving the

parts. The handler design will demonstrate success by regulating the forces

applied by the handler, adding cushioning to the interface, and increasing the

contact area. Thus, reducing the damage introduced to the cylindrical ceramic

parts by handling.

Final Design

Demonstration Video

https://www.youtube.com/shorts/47-8ZaGDmPg

Makada is a current senior majoring in Industrial Engineering at FAMU-FSU College of Engineering. Upon graduation, Makada will be relocating to Chesapeake, Virginia where she will start her career as a Quality Control Engineer with Flowserve. Makada will continue as a mentor and tutor, expanding on her current role as a teacher for the nonprofit organization STEM4Girls.

Erich is graduating in Spring 2022 with a degree in Mechanical Engineering with specialization

in Mechanics and Materials. After graduation, Erich is pursuing a career in MEP engineering with

Rameriz and Azadian Analysis and Design in New York City. He dreams of making eco-friendly

buildings for the future generation.

Charles is graduating in Spring 2022 with a Mechanical Engineering degree with a focus in dynamic

systems. After graduating, Charles is moving to Corning, NY to pursue a career in process engineering

at Corning Inc.

Amelia is a senior studying Mechanical Engineering at the FAMU-FSU College of Engineering. She is specializing in the mechanics of materials. After graduating, Amelia is moving to Blacksburg, VA to start her career as a process engineer for Corning Inc.

created with

Offline Website Builder Software .