Sponsor and Advisor

Mike Conroy

Project Sponsor

Florida Space Institute

Keith Larson

Project Advisor

FAMU-FSU College of Engineering

Project Sponsor

Florida Space Institute

Project Advisor

FAMU-FSU College of Engineering

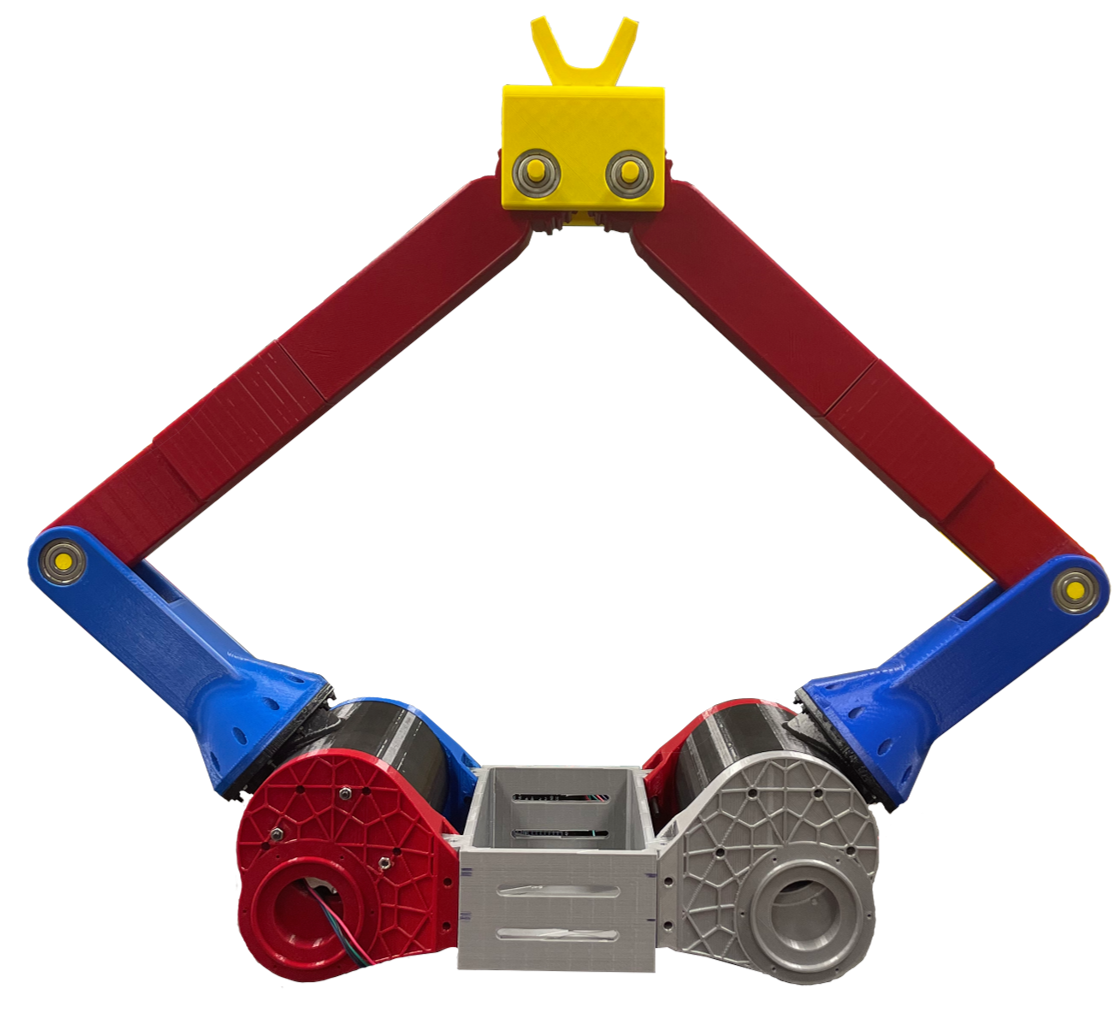

Due to the high cost of traveling to the moon Florida Space Institute proposes RASSOR, a NASA mining robot, to become a general-purpose robot. Achieving this will allow astronauts to use RASSOR for different purposes by replacing different parts. Our project repurposes RASSOR into a transport system which uses multiple robots working together to lift heavy and large objects. Our design is tested on the RE-RASSOR platform, the ''RE'' standing for research and education, which is a scaled down, fully 3D printed version of the original RASSOR robot.

The design can be split into two main components: the lifting mechanism and the payload connection. The lifting mechanism replaces the original digging drums with a five-bar mechanism to create 25 pounds of lifting force. This allows the use of the existing RE-RASSOR shoulder motors. The payload connection includes a cylindrical shaped peg rigidly attached to the payload and a U-shaped connector on the lifting mechanism. The robot lifts the payload directly under the peg and cups it with the V-shaped connector, allowing the ability to rock the payload. This ability becomes useful to adjust the angle of the payload and to balance the weight across multiple robots against uneven surfaces. This design successfully uses 4 robots to lift 100 earth-pounds, which is about 600 pounds on the moon, and handle inclines up to 5 degrees.