Team 522 - Rockwell Automation Manufacturing Device for Students

Abstract

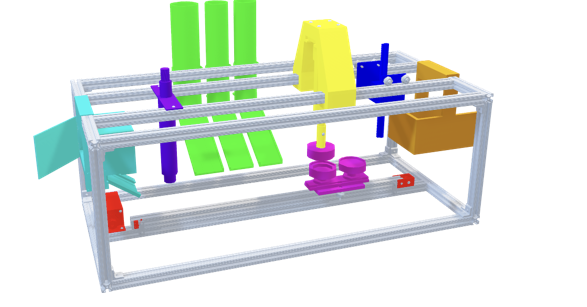

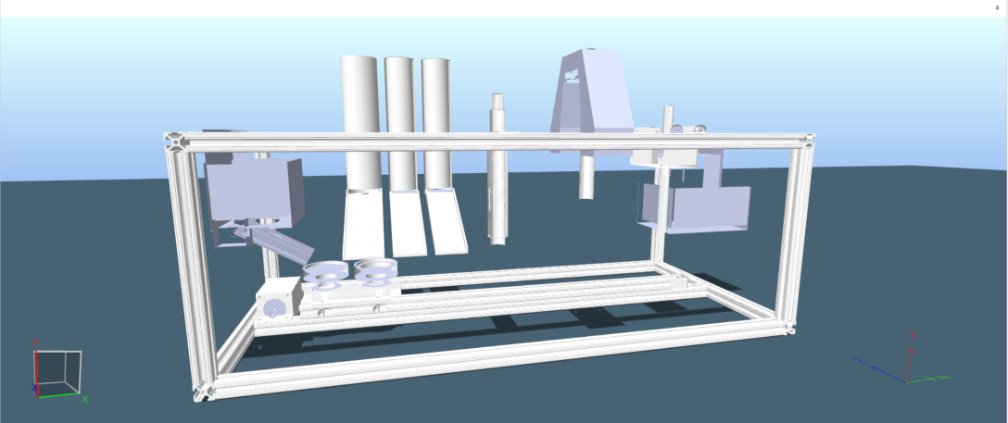

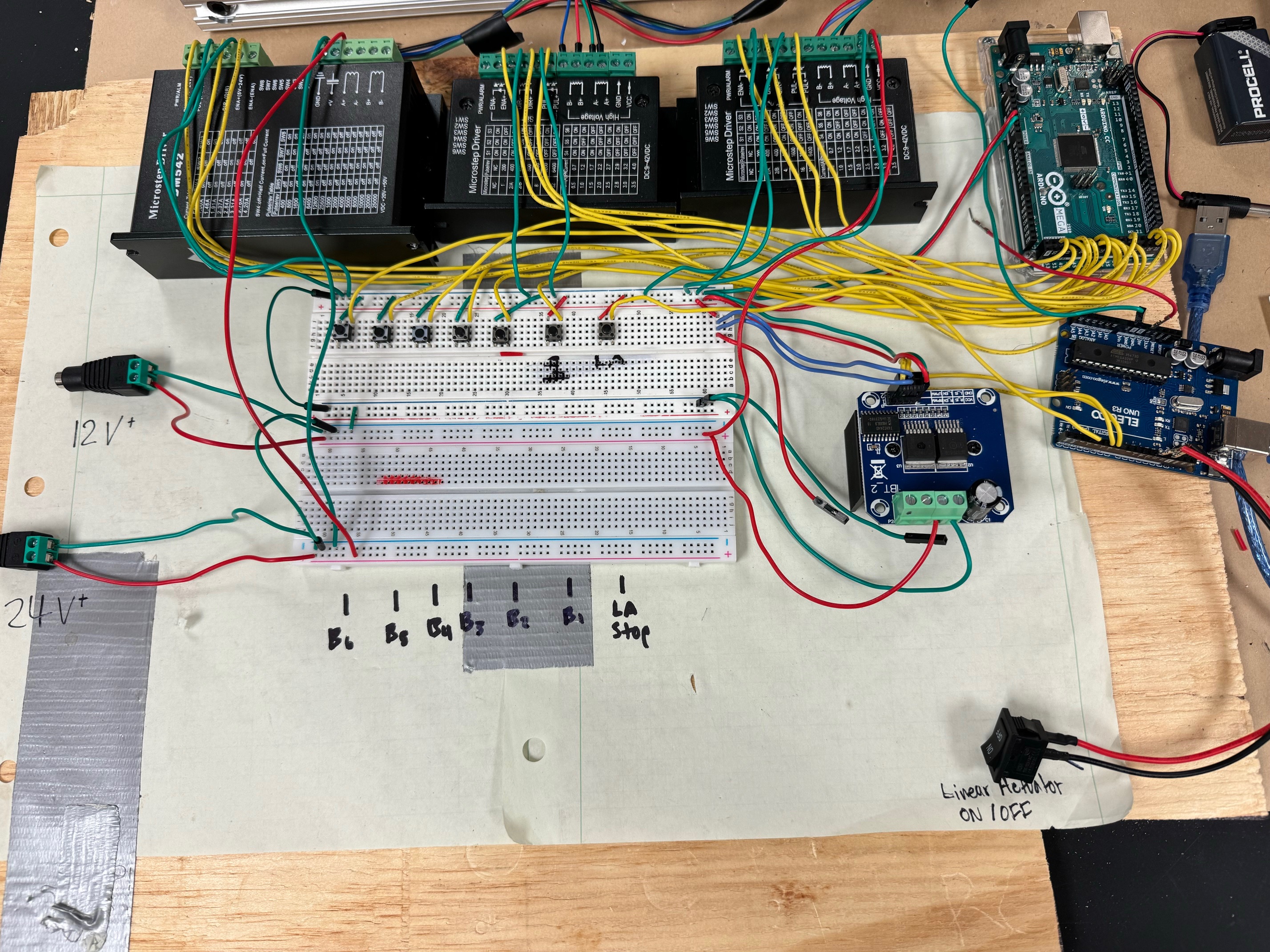

Our team is working with Rockwell Automation to create a project demonstrating automated manufacturing for K-12 audiences. Team 522 aims to educate students about manufacturing and STEM topics by building a system that produces metal pins. The system is designed to make one pin per minute and is safe for children to observe. It consists of stations showcasing different manufacturing processes, including a step where students can personalize designs. The system ensures quality control of inputs and outputs. It can display manufacturing steps on a screen while processing the pin, keeping users engaged. The team uses CAD and emulate3D software for design and testing, and Rockwell hardware for the physical model. The goal is to create a system that Rockwell can proudly showcase for public engagement in automated manufacturing.