Team 03: Eglin/AFRL 1: Compact Pneumatic UAV Launcher

2008 - 2009 Senior Design

E: LaunchTeam09@gmail.com

Adewale Adelakun, Timothy Bartlett, Enye' Blocker & Jared Rodriguez

Project Overview

Deliverables

The Ice Breaker - Pasta Bridge

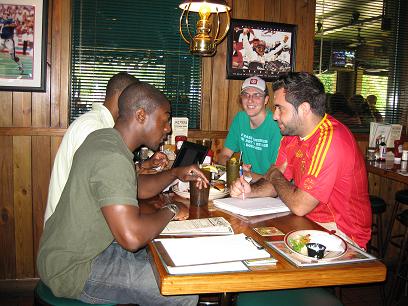

We gathered at Enye's place to work on the pasta bridge. After a few minutes of disscussion and assessing our materials, we came up with a general ideal for our bridge; keep it simple. Along with keeping it simple, we decided to use different types of pasta to increase the strength and density of the bridge. We tried to pack the pasta as tightly as possible.

Here is a list of our materials:

Here is a list of our materials:

- 1 box of Mannicotti

- 2 boxes of Vermicelli

- 2 boxes of Lasagna

- 6 bottles of various super glue

We started by stuffing the Mannicotti with the Vermicelli. Because the Vermicelli is very thin, we were able to pack it tightly inside the Mannicotti. We used glue to secure the ends of the Vermicelli inside of the Mannicotti. (Pictured right)

We started by stuffing the Mannicotti with the Vermicelli. Because the Vermicelli is very thin, we were able to pack it tightly inside the Mannicotti. We used glue to secure the ends of the Vermicelli inside of the Mannicotti.

Here is our finished product!!

The Compact Pneumatic UAV Launcher

Below are pictures of the UAV that we took when our sponsor came to the FAMU/FSU College of Engineering for a presentation. We have now been cleared for public authorization, so we could post these pictures. We have been hard at work, particularly with conceptual design. We have laid out a schedule that shows we should have a particular design chosen by the weekend of October 10th. Keep looking for Updates!

(Pictured to the left) Wale holds the UAV to show a view from the front when the wings are retracted. You can see that the back wings fold under the UAV and the front wings fold over the top. This might pose a problem when the UAV is exiting the lanch tube.

(Pictured to the right) A side view of the UAV is taken. The front of the aircraft is to the left. This picture gives one a better view of the profile of the UAV. The un-uniform shape will make it difficult to get a good seal in the tube to achieve maximum efficiency. We have been conceptualizing inorder to find alternative ways of achieving optimal results.

(Pictured to the left) The UAV is now full span. This picture is from the underside of the aircraft. The hard plastic on the bottom end of the craft might be a good point to use when applying pressure to launch. The carbon fiber body is tough, but might not be able to withstand the impact brought on by high pressure forces impacting the surface.

The UAV is pictured in flying position with the front to the right. Not pictured is the propeller that will be engaged once the UAV is in-flight or the electronics that will be inside the UAV. The UAV as a whole will weigh 3.5 lbs while the launching system cannot exceed 2.5 lbs.

Meet The Team

Adewale Adelakun

Hello, I'm Adewale "Wale" Adelakun and I'm from the San Francisco bay area, California. I chose mechanical engineering because I'm a big car guy. My dream job is driving for an F1 or rally team, but realistically, I intend to work in the defense industry.I work as a personal trainer and as a crew member on an SCCA Spec Miata race team on the weekends. This project was my first choice, and I haven't looked back since the project began.

Timothy Bartlett

Hello, I am Tim Bartlett and I am from Casselberry, Florida. At an early age, I became fascinated by how different things were put together and how this governed their motion. This interest led me to mechanical engineering. I am specializing in thermal fluids. This project was my first choice as well. I look forward to completing the challenges this project has to overcome.

Enye' Blocker

I am Enye' Blocker a senior Mechanical Engineering student from Birmingham, AL. I originally chose engineering with a serious interest in robotics but I have since found the oil and gas industry quite attractive considering several years of relevant internship experience with Shell Oil Company. I am really excited about this project and look forward to achieving all of the goals we have set forward.

Jared Rodriguez

My name is Jared Rodriguez and I reside in Tampa, Florida. I am 23 years old and have always been a Seminoles fan. I came to Florida State University my sophomore year and chose to major in Mechanical Engineering. I have been building and taking things apart my whole life. It started with legos and has culminated into this project. This project was my first choice on the list we were given. I spent this past summer at an internship at McQuay International in Staunton, VA. I also play/coach on the Florida State Men's club soccer team.